Continuous hydrothermal carbonization system and process for livestock and poultry excrement

A technology of livestock and poultry manure and carbonization system, which is applied in the field of resource utilization of livestock and poultry breeding waste, can solve the problems of complexity and high energy consumption, achieve low production costs, reduce equipment production and operation costs and energy consumption, and promote flow and the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

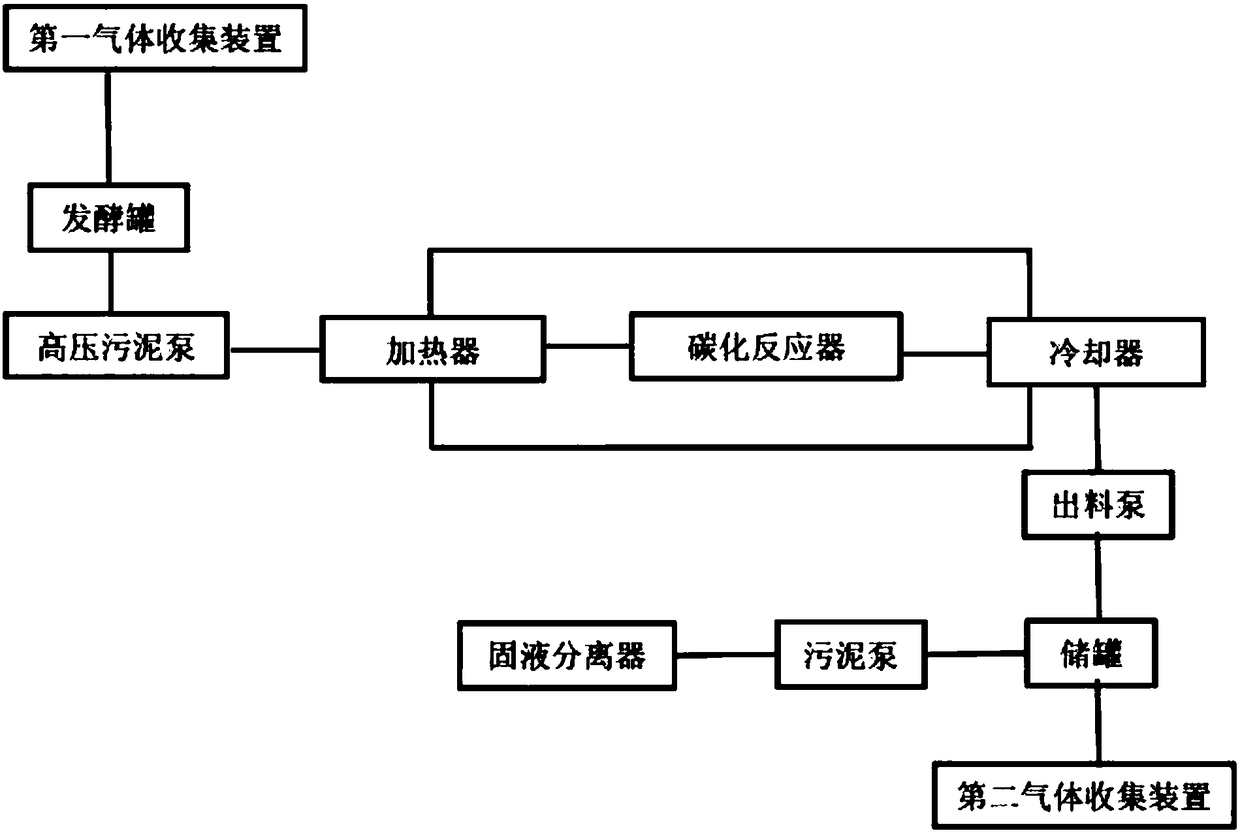

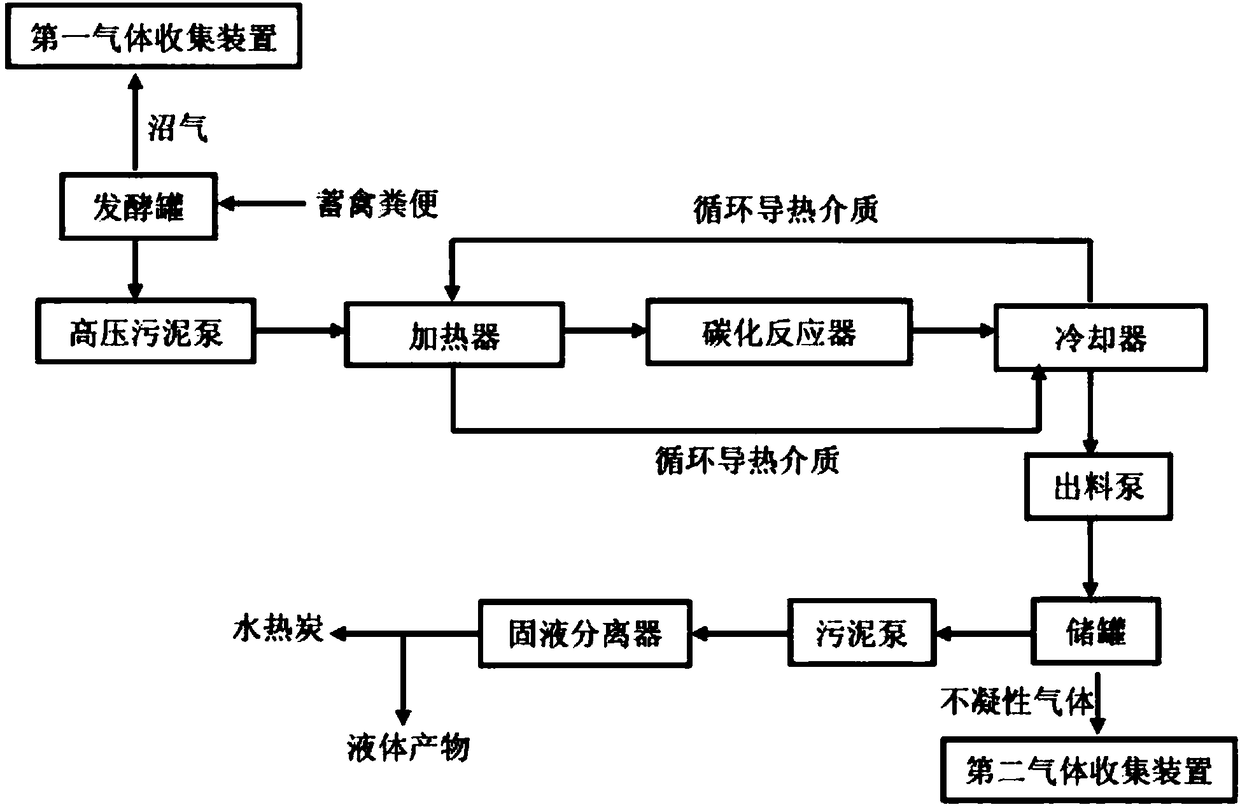

[0038] A continuous hydrothermal carbonization system for livestock and poultry manure, such as figure 1 As shown, it includes a fermenter, a high-pressure sludge pump, a heater, a carbonization reactor, a cooler, a storage tank, a sludge pump, and a solid-liquid separator connected in sequence, and the fermenter is also connected to the first gas collection device through a pipeline, and the storage The tank is also communicated with the second gas collection device through pipelines, the first pipeline and the second pipeline are arranged between the cooler and the heater, and the heater, the first pipeline, the cooler and the second pipeline form a heat cycle; The stirrer, the heater, the carbonization reactor and the cooler are all equipped with screw stirrers.

[0039] The first gas collection device is used to collect biogas produced after the fermentation of livestock and poultry manure, and the second gas collection device is used to collect non-condensable gas generat...

Embodiment 2

[0056] A continuous hydrothermal carbonization system of livestock and poultry manure is the same as that in Embodiment 1, except that the circulating heat transfer medium is heat transfer oil.

[0057] A continuous hydrothermal carbonization process of livestock and poultry manure, such as figure 2 shown, including the following steps:

[0058] (1) The water content of livestock and poultry manure after pretreatment is 85%, and it is placed in a fermenter, and a cow dung fermentation agent is added at the same time, and digested fecal sludge is obtained after anaerobic fermentation for 10 days. Gas collection device collection;

[0059] (2) The digested fecal sludge obtained in step (1) is continuously input into a heater at a speed of 100 L / h through a high-pressure sludge pump, and then enters a tubular carbonization reactor for hydrothermal carbonization reaction to obtain a carbonized product;

[0060] (3) After the carbonized product obtained in step (2) is cooled by ...

Embodiment 3

[0068] A continuous hydrothermal carbonization process of livestock and poultry manure, such as figure 2 shown, including the following steps:

[0069] (1) The moisture content of livestock and poultry manure after pretreatment is 65%, placed in a fermenter, and digested fecal sludge is obtained after anaerobic fermentation for 8 days. At the same time, the generated biogas is collected by the first gas collection device, and added to the Concentrated sulfuric acid with 0.75% of fecal sludge mass percentage is used to adjust pH;

[0070] (2) The digested fecal sludge obtained in step (1) is continuously input into a heater at a speed of 150L / h through a high-pressure sludge pump, and then enters a carbonization reactor for hydrothermal carbonization reaction to obtain a carbonization product;

[0071] (3) After the carbonized product obtained in step (2) is cooled by the cooler, it enters the storage tank after the discharge pump releases the pressure. The non-condensable ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com