A method for recycling and utilizing spent cathode carbon blocks from electrolyzer overhaul slag

A technology of waste cathode carbon block and overhaul tank slag, which is applied in the direction of carbon preparation/purification, etc., can solve problems such as the influence of cement strength, inability to achieve, and fluorine air pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

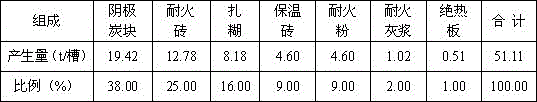

[0023] Embodiment 1 of the present invention. The method for recycling the spent cathode carbon block of electrolyzer overhaul slag comprises the following steps:

[0024] a. Sorting the overhaul slag of the electrolyzer to obtain the spent cathode carbon blocks.

[0025] b. Carry out water immersion to waste cathode carbon block, fluoride salt is dissolved in water, and the cathode carbon block that has absorbed fluoride salt will disperse, obtain the powder material and block material that immerse and disperse, select the block material among them, The selected block material has less fluoride salt adsorbed, the selected block material is crushed, soaked in water again to further remove the fluoride salt, and the selected block material is dried again as the aggregate for making the cathode carbon block, and the remaining The powder is subjected to grinding treatment, and then flotation to obtain carbon powder. The aggregate and carbon powder of the obtained cathode carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com