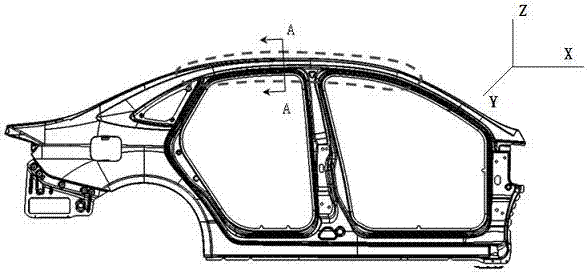

A structure and its design method of the overlapping area of the top cover of the outer panel of the automobile side wall

A side wall outer panel and area structure technology, which is applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problem of side rebound of side wall outer panel and top cover overlapping area, and material utilization rate of side wall outer panel Low, cracked door openings on the outer panel of the side wall, etc., to reduce the risk of springback, improve the appearance quality, and ensure that the A surface is not deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

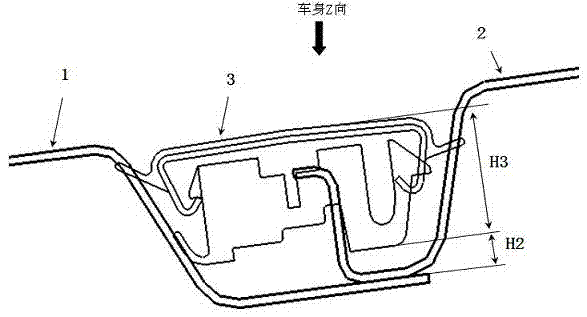

[0043] Combine below Figure 4 , the present invention is further described:

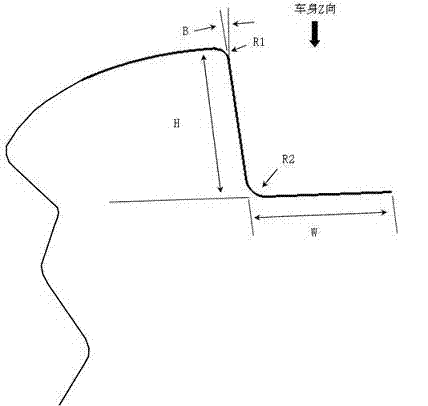

[0044] At the joint between the side wall outer plate and the top cover outer plate, the shape of the side wall outer plate is convex and arc-shaped. According to the material forming principle, when the side is shaped, due to the anisotropy of the material, it is easy to cause the A side of the side wall outer plate (ie The deformation of the exterior surface of the car), and the welded surface after side shaping is prone to wrinkling, stacking and springback.

[0045] Over-drawing, side shaping stamping process is adopted in the overlapping area of the top cover of the side wall outer plate. If the depth of the side shaping steps is inconsistent, there will be serious deformation defects on the A surface of the part after side shaping. In order to reduce the risk of surface A deformation caused by side shaping, improve the structural strength of the upper part of the part, and reduce the risk o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com