Structure for realizing automatic de-molding of product by utilizing line thimble

An automatic demoulding and positioning technology, applied in the field of mold structure, can solve problems such as inability to eject products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

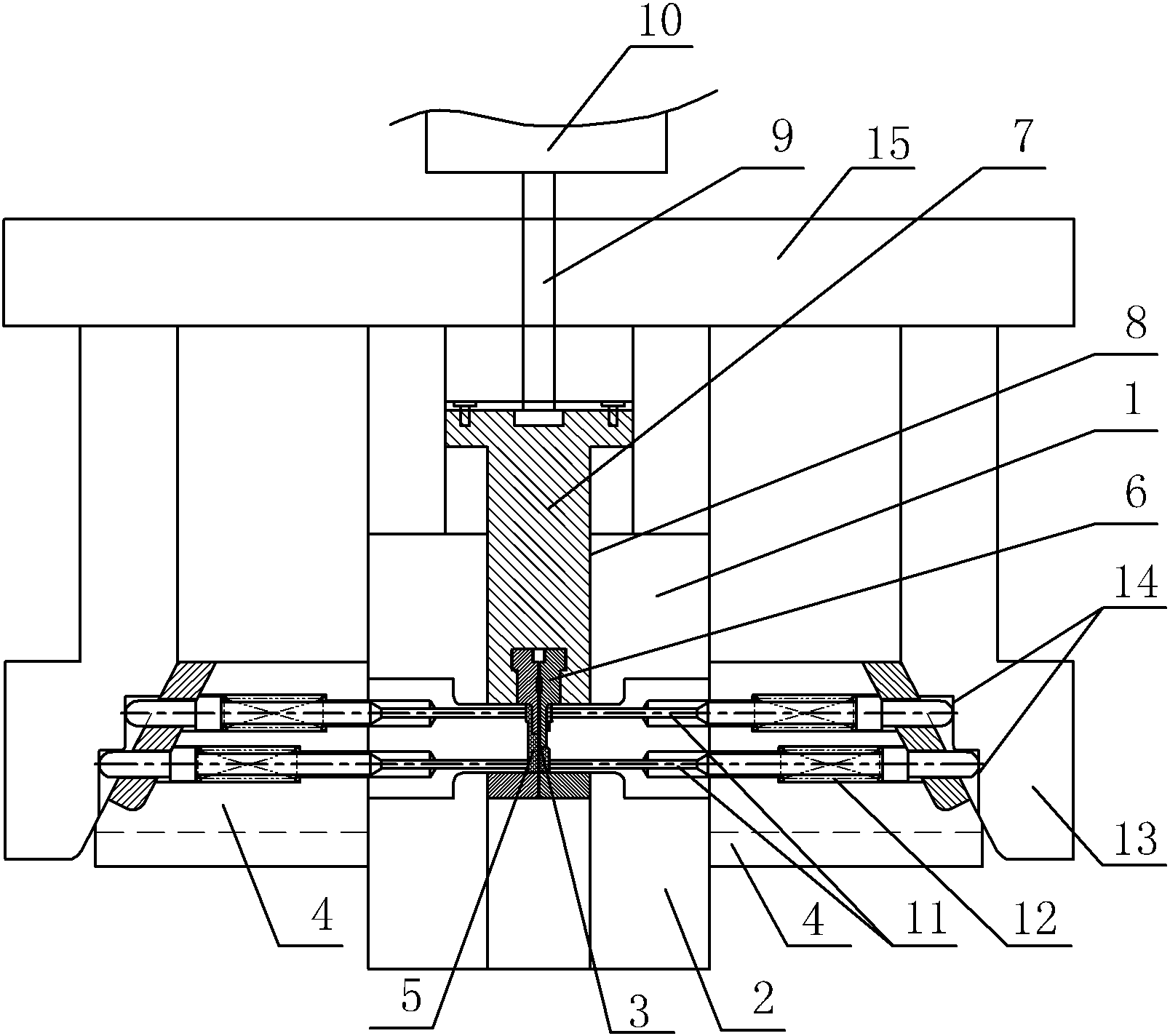

[0008] See figure 2 , which includes a front mold core 1, a rear mold core 2, a front mold insert pin 3, and inserts 4 on both sides. 3 goes deep into the cavity 5, the front mold needle 3 runs through the front mold needle fixed structure 6, and the front mold needle fixed structure 6 is fastened to the front mold needle first core-pulling mechanism 7 on its upper part, and the front mold needle first The core-pulling mechanism 7 penetrates the straight line groove 8 of the front model core 1, and then its top is fastened to the driving structure 10 by bolts 9. The inserts 4 on both sides are respectively provided with row position thimbles 11, and the middle parts of the row position thimbles 11 are all provided with row position thimbles. The thimble return spring 12, the tail of the row position thimble 11 is mounted on the delay ejection mechanism 14 of the row position shovel 13, and the upper part of the front model core 1 is fastened with the upper fixing plate 15 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com