Apparatus and method for bonding fibers

一种粘合装置、粘合纤维的技术,应用在喷射装置、液体喷射装置、家用元件等方向,能够解决粘合剂用量高等问题,达到用量最小化、优化控制和调节的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

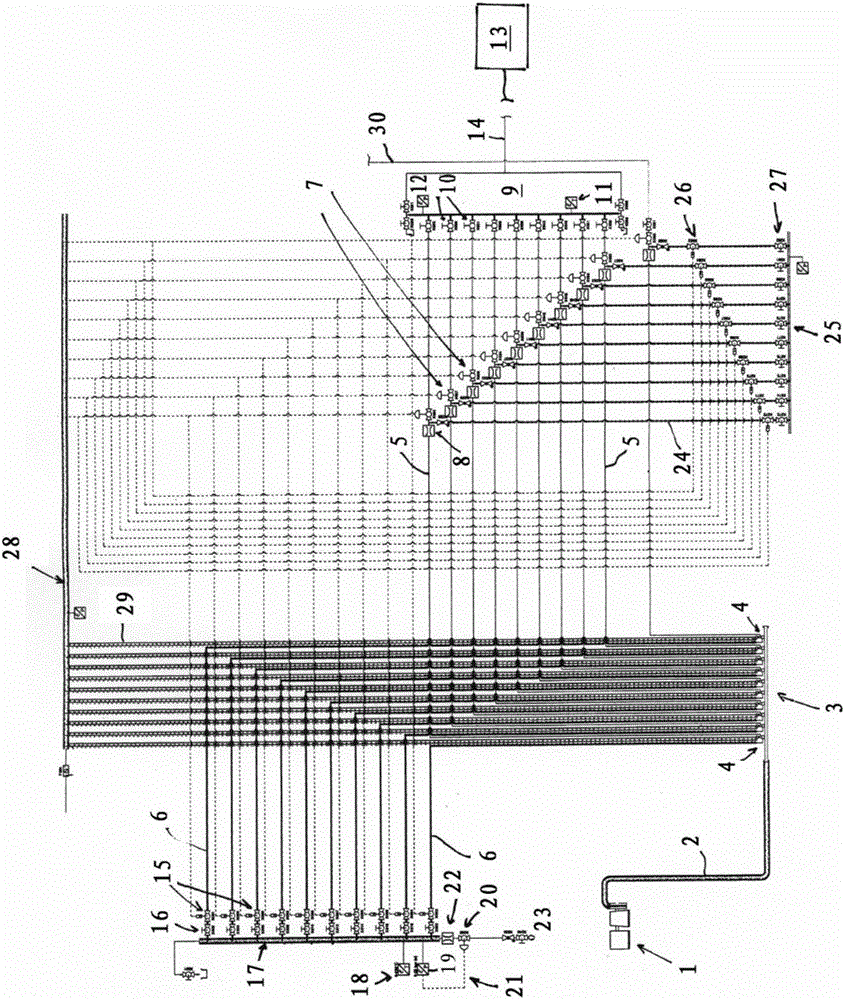

[0026] The drawings show a bonding device for bonding fibers or similar particles for the manufacture of wood boards, for example fibreboards. Therefore, this bonding device is integrated in a plant for the production of wood panels.

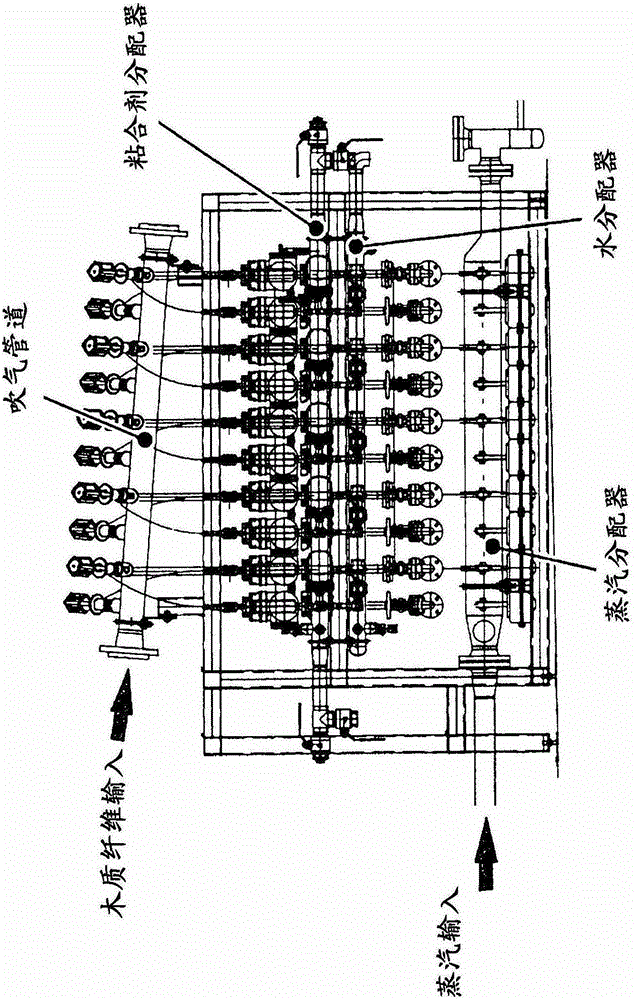

[0027] The fibers are produced, for example, from wood chips in a defibrator or refiner 1 in a known manner. The high steam pressure present in the refiner is used to blow the fibers from the refiner 1 via the fiber delivery line 2 into the blow line 3 , which is also referred to as the “blow-line”. The blowing duct has a smaller diameter, for example 50 mm to 200 mm, preferably 80 mm to 120 mm. The blowing duct 3 can be provided with one or more pressure sensors respectively on the input side and the output side, these pressure sensors are not shown in the figure. A plurality of nozzles 4 are connected to the blowing duct 3 , with which the fibers conveyed through the blowing duct can be sprayed with adhesive. In this exemplary embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com