Rectification method for improper flanging angle and uneven flanging surface of automobile L-shaped stamping parts

A stamping and L-shaped technology, which is applied in the field of rectification of insufficient flanging angle and uneven flanging surface of automotive L-shaped stamping parts, which can solve the problem of uneven flanging surface of L-shaped stamping parts, large matching gap, affecting welding quality, etc. problems, to achieve the effect of ensuring accuracy and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The L-shaped stamping parts on the car are mainly formed by the forming process, and the flanging angle is 90 degrees or greater than 90 degrees.

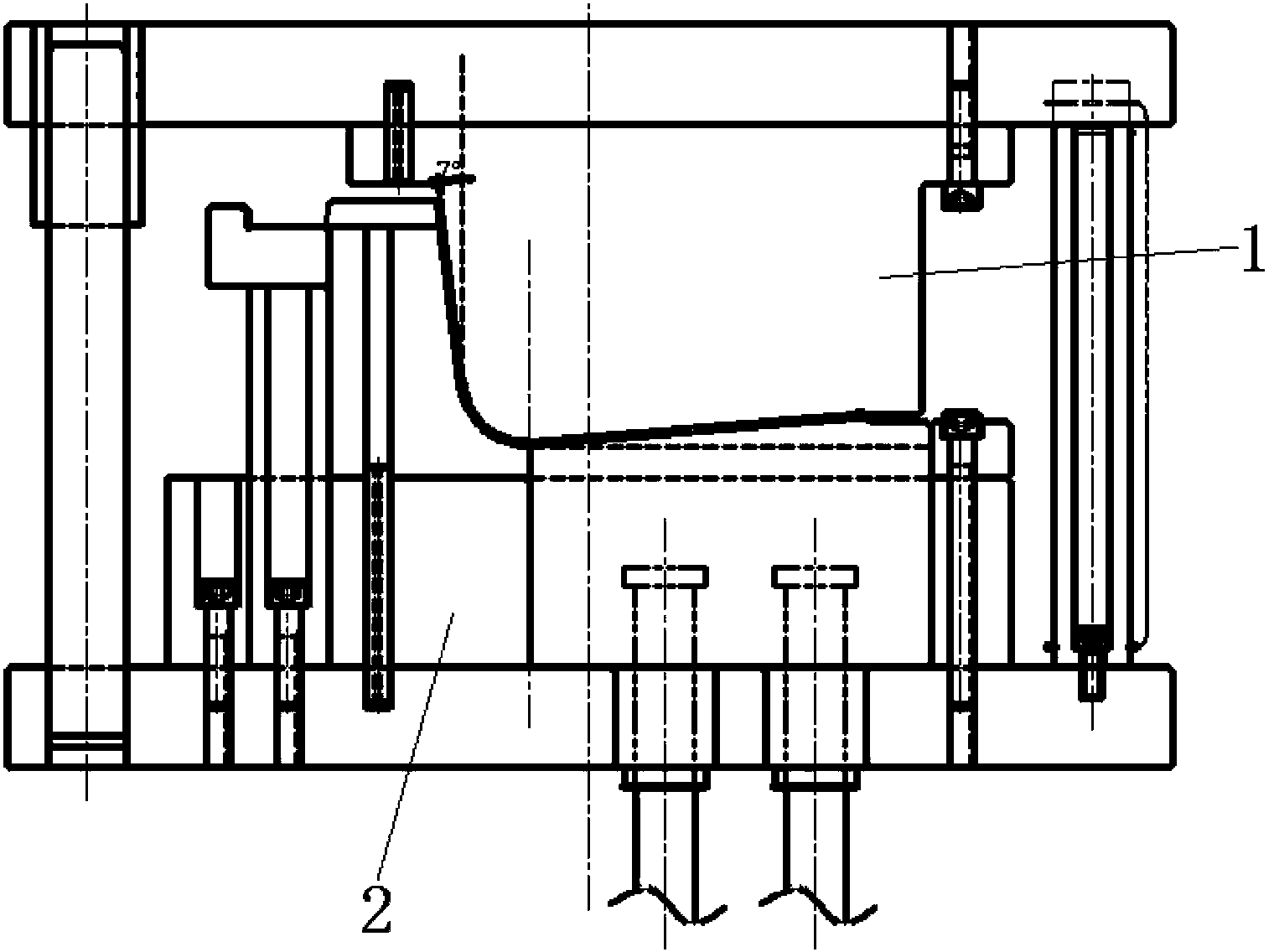

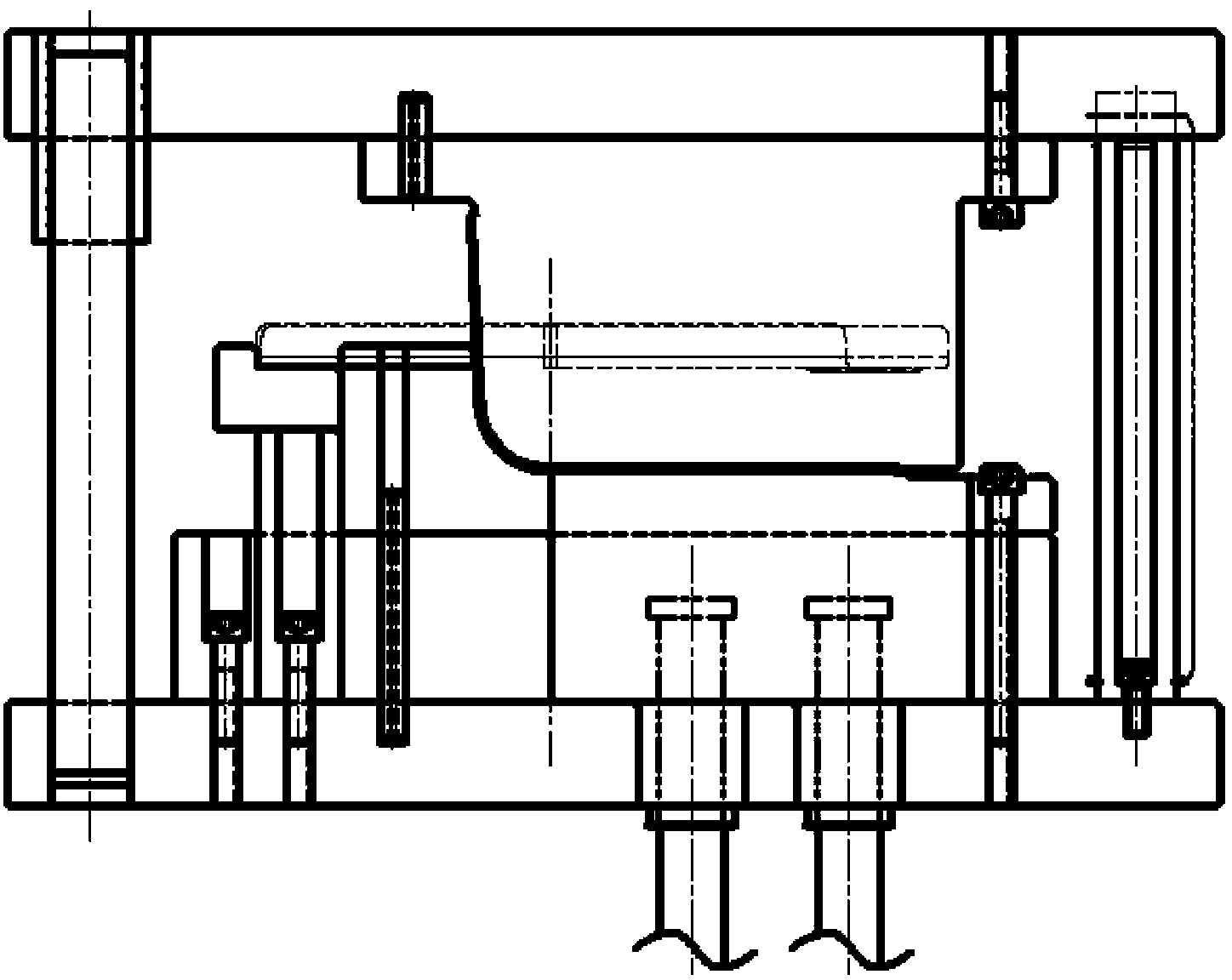

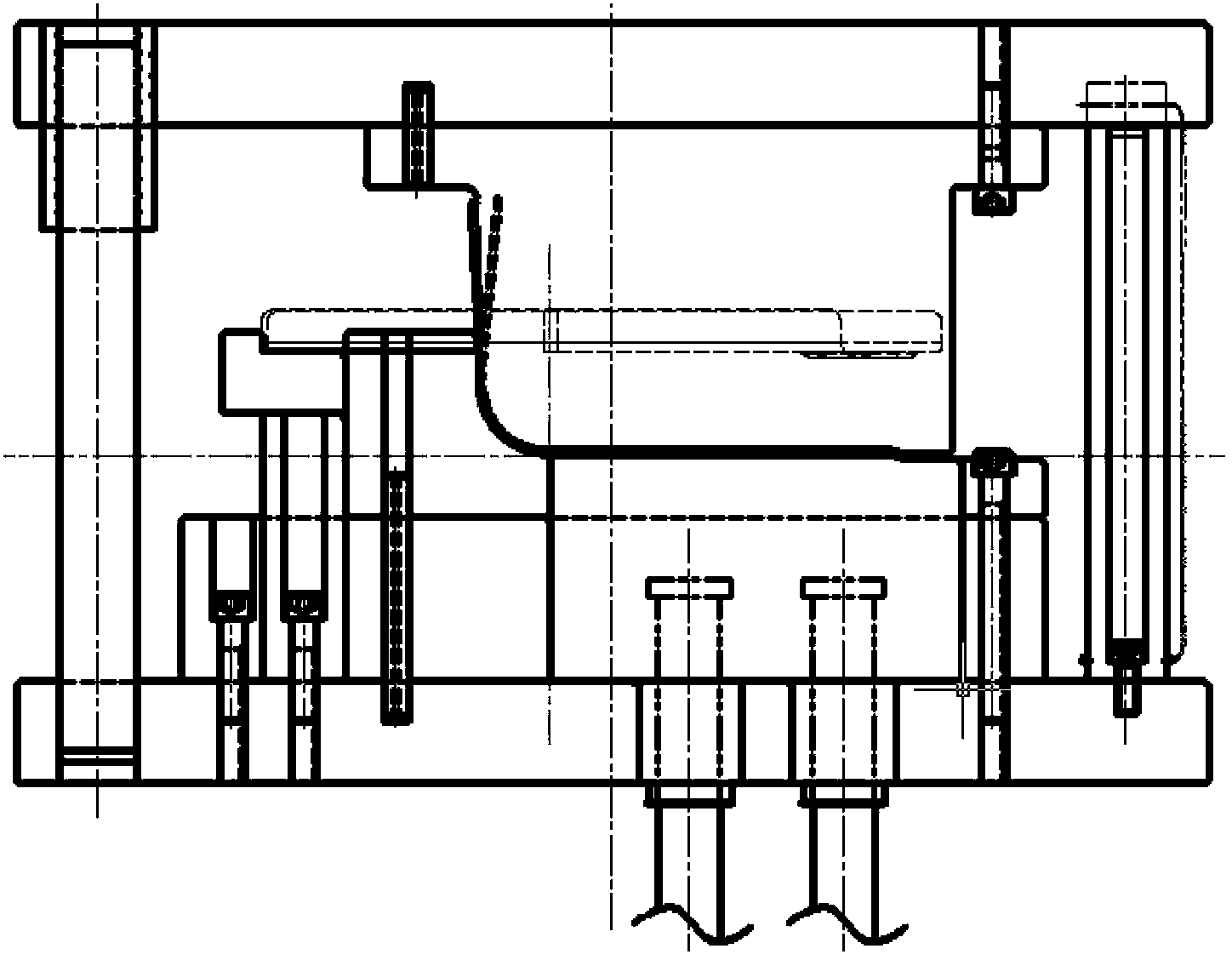

[0019] The invention discloses a method for rectifying the flanging angle of an L-shaped stamping part of an automobile that is not in place and the flanging surface is uneven, such as figure 1 As shown, in the stamping process of L-shaped parts, the die 2 of the mold includes the flanging surface of the stamping part, the working surface of the side part of the die 2 and the working face of the side part of the punch 1 are inclined outwards, and the concave The working surface on the upper part of the mold 2 is a slope inclined downward toward the side of the die 2, and the working surface on the upper part of the punch 1 is a slope inclined downward toward the side of the punch 1, and the workpiece is rotated on the mold for 2~ 7 degrees, the rebound process allowance is reserved on the part, so that the stamping angle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com