A kind of processing method of golden camellia purple bud green tea

A processing method and technology of golden camellia, which is applied in the processing field of golden camellia purple bud green tea, can solve the problems of not obvious aftertaste, opaque soup color, loss of anthocyanins, etc., and achieve obvious aftertaste, unique quality and sweet taste alcohol effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

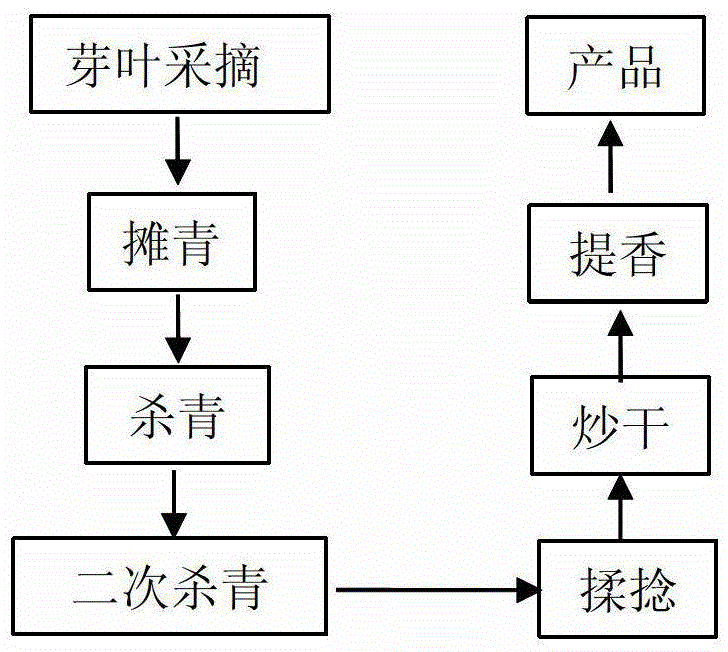

Method used

Image

Examples

Embodiment 1

[0027] Pick 40kg of golden camellia with one bud and one leaf and one bud and two leaves of purple buds as raw materials. The fresh leaves are placed in an air-conditioned room to spread green. The humidity in the air-conditioned room is 80%~90%. 1~2cm, put it on a bamboo mat and stand green for 7 hours, until the leaves become soft, and the water loss rate of fresh leaves is 18%. Spread the green leaves for microwave killing, the temperature is 100°C, and the time is 2 minutes. The killing standard should reach full ripeness, the green gas is lost, and the hand feels soft, and then spread for 30 minutes. Put the first greening leaves into the roller greening machine, carry out the second greening, the temperature is 200 ℃, when the water loss rate of the green leaves reaches 70%, finish the second greening, and knead while it is hot. The kneading method is to press lightly for 18 minutes first, then press for 5 minutes, and finally loosen the pressure for 26 minutes. Knead t...

Embodiment 2

[0030] Pick 60kg of golden camellia tea with one bud and two leaves and purple buds as raw materials, and put the fresh leaves in an air-conditioned room to spread green. The humidity in the air-conditioned room is 80%~90%, and the indoor temperature is kept at 22°C. Spread green on the bamboo mat for 7 hours, until the leaves are soft, and the water loss rate of fresh leaves is 30%. Spread green leaves to carry out microwave deenzyming, temperature is 105 ℃, time is 5min, the standard of deenzyme should reach complete ripeness, green gas dissipates, feel soft, then spread out to cool for 30min. Put the first-time greening leaves into the roller greening machine for secondary greening at a temperature of 240°C. When the dehydration rate of the green leaves reaches 75%, finish the second greening and knead while it is hot. For kneading, press lightly for 20 minutes first, then press for 10 minutes, and finally loosen the pressure for 25 minutes. Knead the leaves and put them i...

Embodiment 3

[0033] Pick 20kg of golden camellia with one leafless bud and one purple bud with one leaf as raw materials. Place the fresh leaves in an air-conditioned room to spread green. The humidity in the air-conditioned room is 80%~90%. 1~2cm, placed on a bamboo mat for 7 hours, until the leaves become soft, and the water loss rate of fresh leaves is 25%. Spread green leaves to carry out microwave killing, temperature is 108 ℃, time is 6min, the killing standard should reach fully ripe, green gas dissipates, feel soft, then spread cool 30min. Put the first-time greening leaves into the roller greening machine for secondary greening at a temperature of 230°C. When the water loss rate of the green leaves reaches 65%, finish the second greening and knead while it is hot. For kneading, lightly press for 25 minutes first, then press for 7 minutes, and finally loosen the pressure for 24 minutes. Knead the leaves and put them into a drum frying machine to dry and set the shape until the tea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com