Apparatus and method for charging nanoparticles

A nanoparticle and equipment technology, applied in the field of nanoparticle charging equipment, can solve the problems of not being able to be used on an industrial scale, difficult charging of nanoparticles, and ineffective charging of nanoparticles, and achieve the effect of uniform flux or distribution and uniform flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

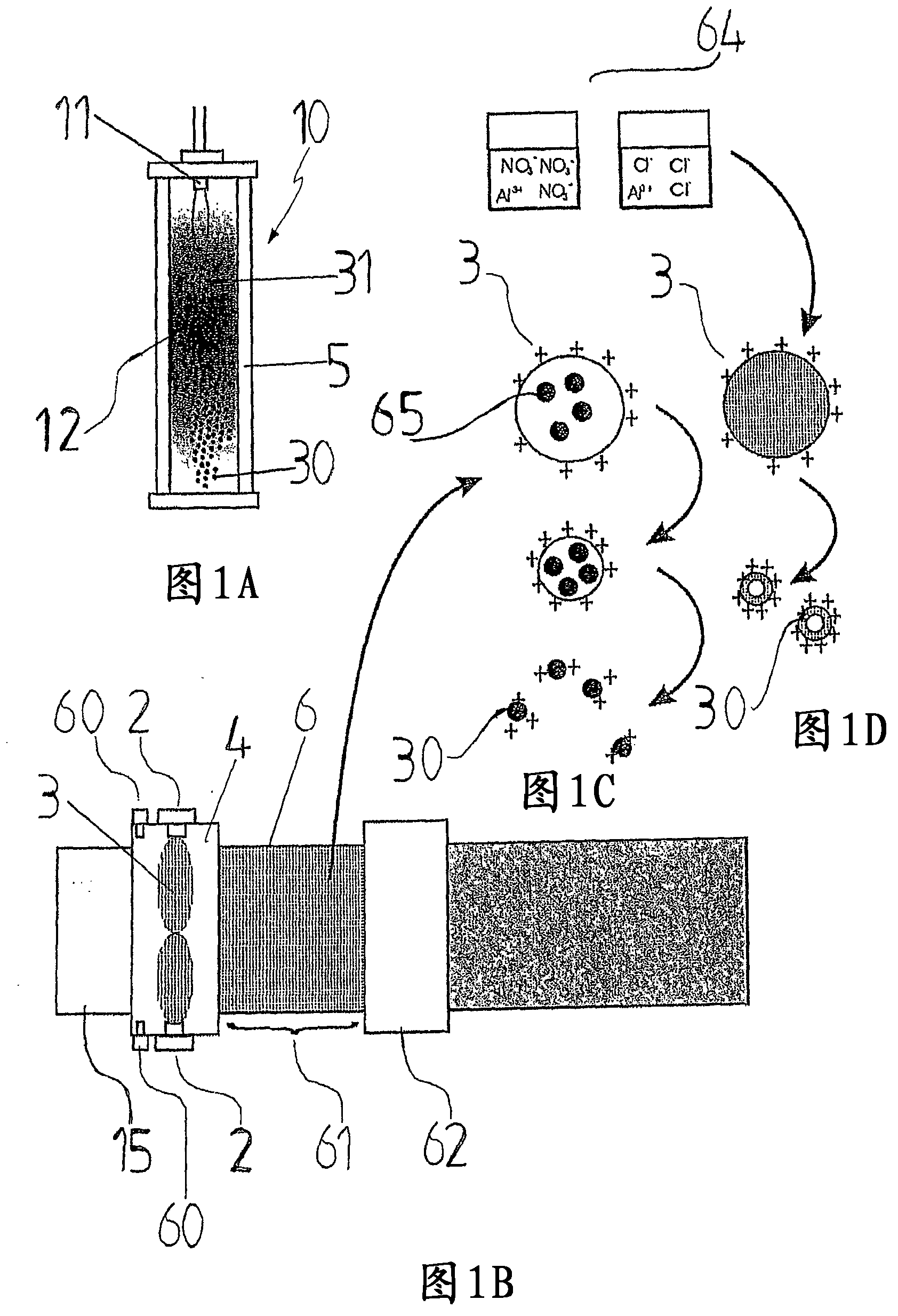

[0012] Figure 1A Device 10 for producing nanoparticles 30 is shown. Device 10 includes an atomizer 11 for atomizing one or more liquid feedstocks into droplets 31 in chamber 5 . The liquid feedstock is preferably atomized using a two-fluid atomizer 11, wherein one or more atomizing gases are supplied to the two-fluid atomizer 11 to atomize the liquid feedstock into droplets 31 . The formed droplets 31 are further guided to a flame 12 generated by means of fuel gas and oxidizing gas. The flame 12 is preferably provided by a two-fluid atomizer 11 , by providing the fuel gas and the oxidizing gas from the atomizer 11 , so that the droplets 31 and the flame 12 are formed in the same device. Fuel gas and / or oxidizing gas may also be used as atomizing gas to form droplets 31, or they may be provided independently of the atomizing gas. The droplets 31 enter the flame 12 in liquid form, and in the flame 12 the liquid feedstock is converted into nanoparticles 30, which may have a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com