Plasma catalysis ignition integrated nozzle

A catalytic ignition and plasma technology, applied in combustion methods, combustion chambers, combustion equipment, etc., can solve problems such as complex reaction processes, achieve the effects of reducing activation energy, preventing carbon deposition in nozzles, and avoiding arc discharge at the end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

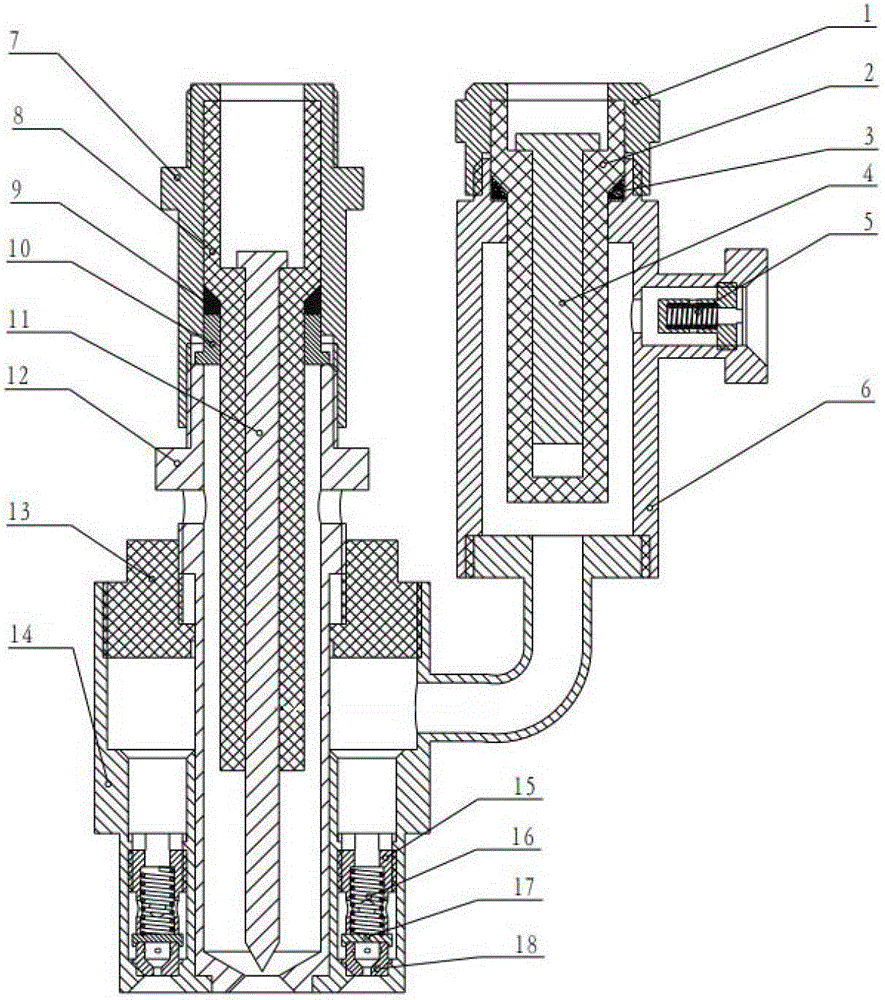

[0022] The structural composition of the plasma catalytic ignition integrated nozzle of the present invention includes a catalytic nut, a catalytic ceramic 2, a gasket, a catalytic cathode 4, a fuel filter 5, a housing 6, an ignition power connector nut 7, an ignition ceramic 8, a gasket 9, Compression ring 10, ignition cathode 11, anode 12, upper cover 13, base 14, compression cover 15, spring 16, swirl cover 17 and swirl piece 18.

[0023] The ignition cathode 11, the anode 12 outside the ignition cathode, the ignition ceramic 8 between the ignition cathode and the anode, and the high-energy plasma ignition assembly composed of the ignition power connector nut 7. A compression ring 10 is arranged between the anode and the ignition ceramic, a certain gap is formed between the anode and the ignition ceramic, and a gasket 9 is arranged at the contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com