Liner supporting device provided with lengthened power spinning tube, supporting bars and ribbed plates

A technology of support device and support rod, which is applied in the fields of pressure vessel machinery, machinery, vehicle-mounted liquefied natural gas storage tank liner support machinery, and liner support device fields, can solve the problem of difficulty in achieving fatigue resistance, lack of scientific rationality, and temperature changes. Deformation and other problems, to achieve the effect of significant and reliable effect, scientific and reasonable design, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

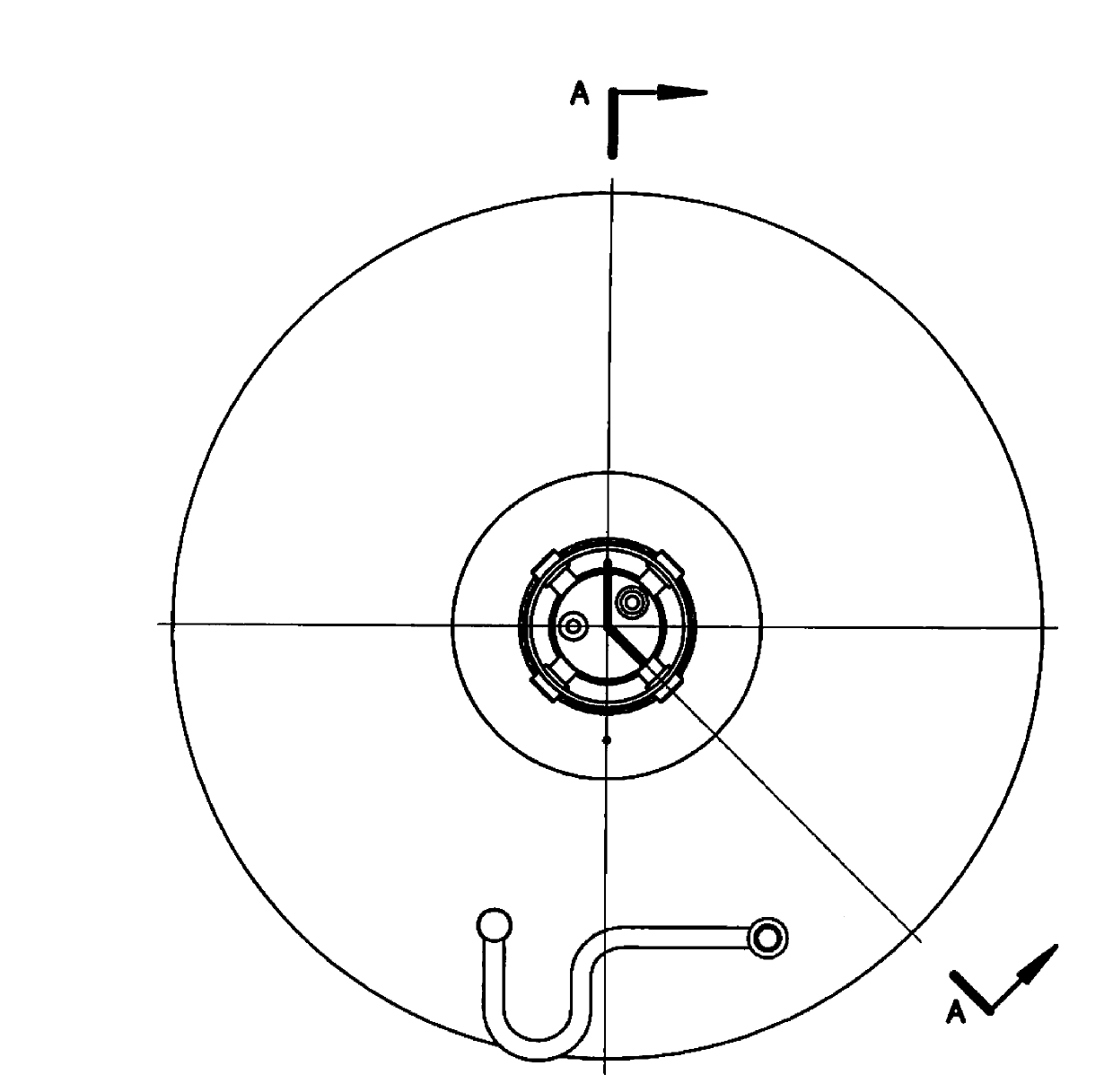

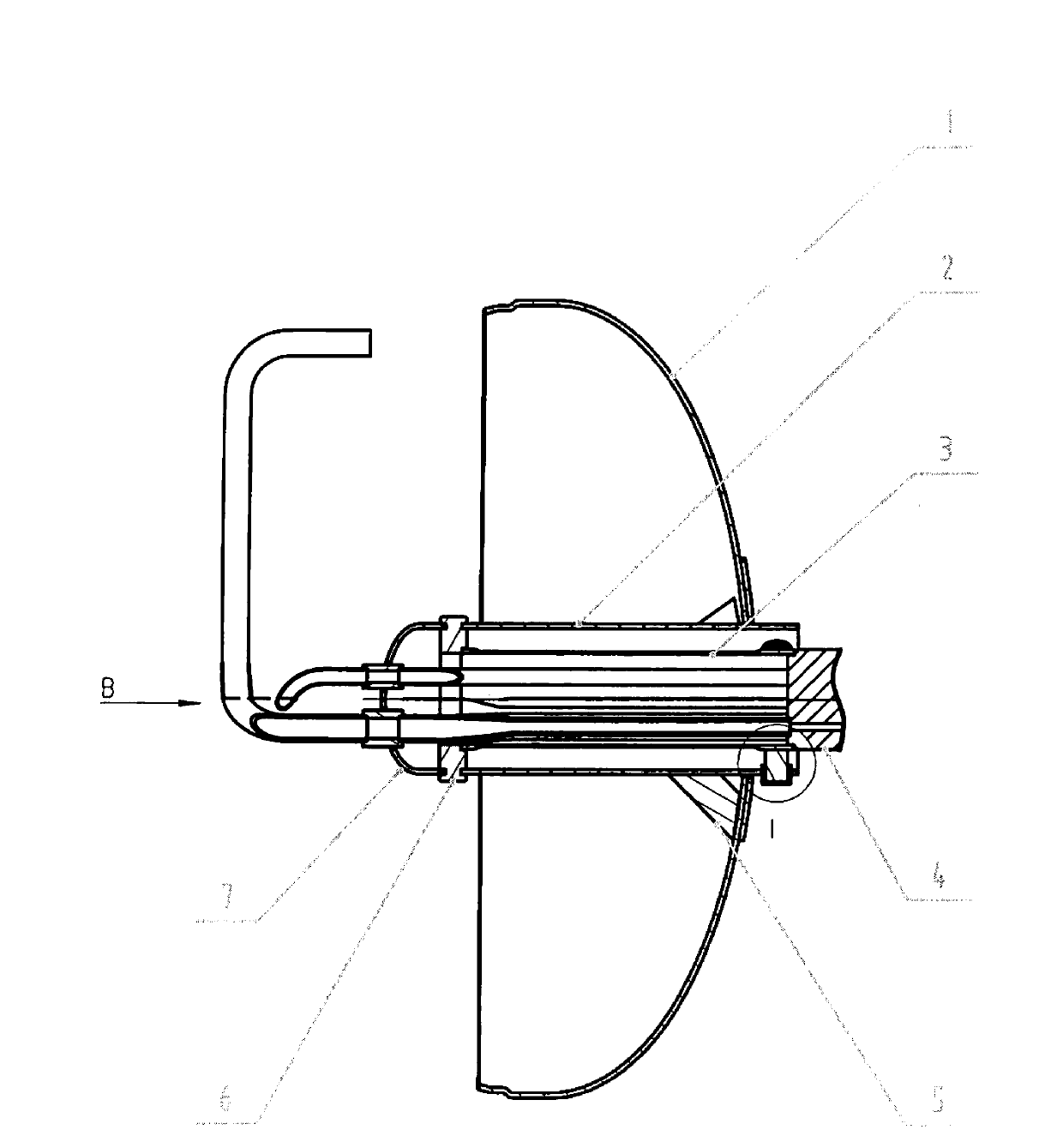

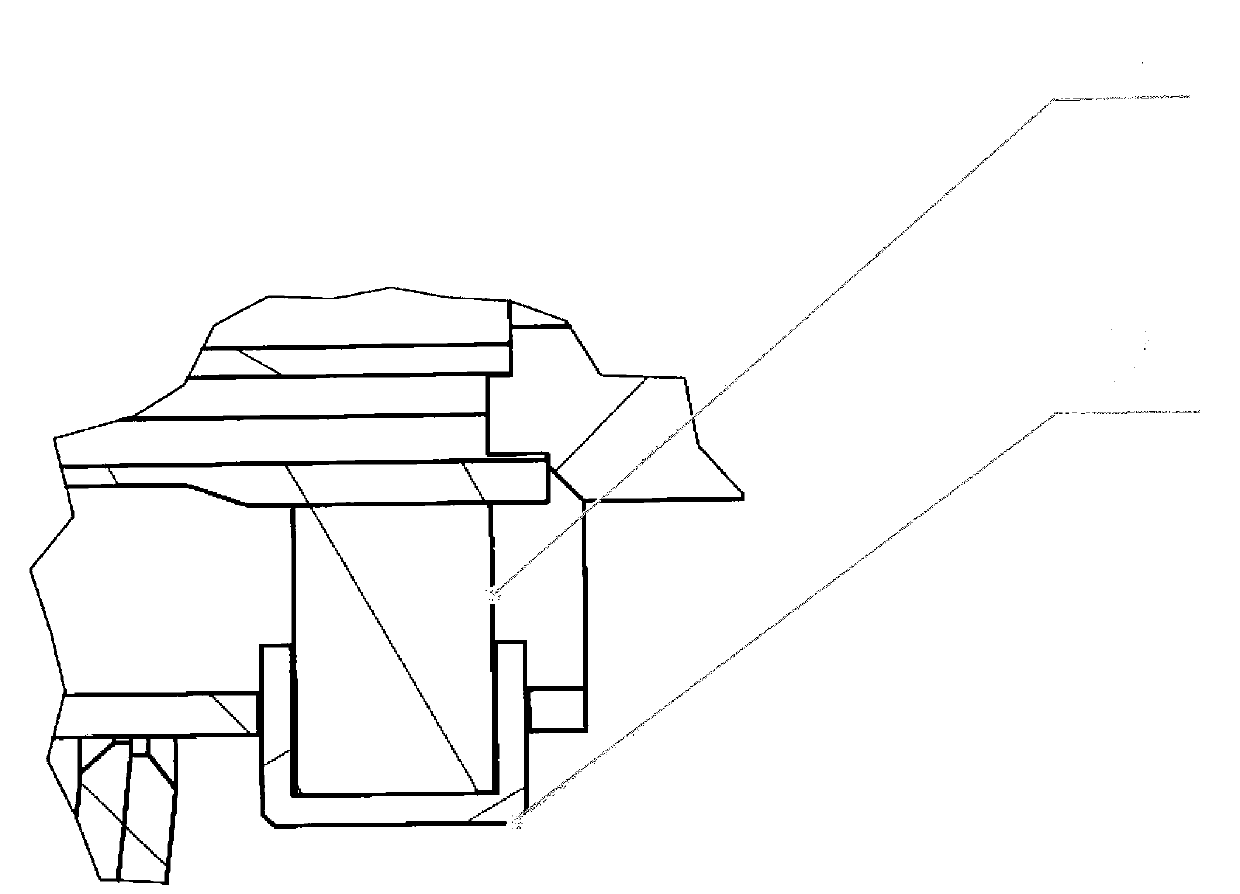

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0029] A liner support device provided with extended strong coils, support rods and ribs, consisting of a front head of the liner 1, a cylinder body 2, a strong coil 3, a manifold valve seat 4, ribs 5, and a support ring 6 , head 7, inflation pipe 8, vent pipe 9, liquid outlet pipe 10, support rod 11, support rod end cover 12;

[0030] In the liner support device provided with extended strong coils, support rods and ribs, the center hole of the front head 1 of the liner and the outer end section of the cylinder 2, the inner end of the cylinder 2 and the support ring 6 One side, the other side of the support ring 6 and the head 7, one side of the support ring 6 and the inner end of the strong coil 3, the outer end of the strong coil 3 and the manifold valve seat 4, one end of the rib plate 5 and the cylinder body 2 while the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com