A Crankcase Combination for Reduced Engine Oil Loss

A technology of crankcase and right crankcase, which is applied in the direction of crankcase ventilation, mechanical equipment, engine components, etc., can solve the problem that the engine oil is easy to be ejected from the exhaust nozzle with the exhaust gas, so as to protect the normal operation, easy to separate, reduce the The effect of abnormal wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

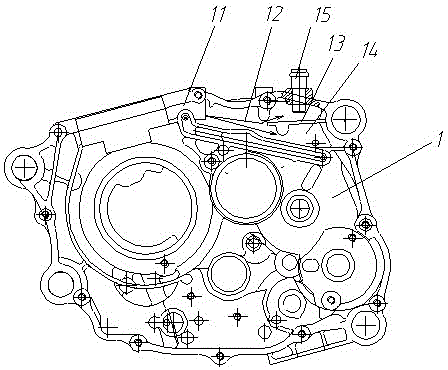

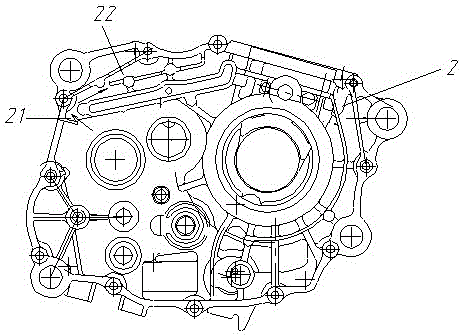

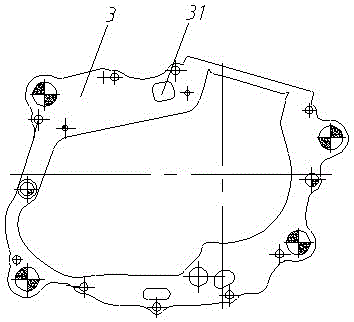

[0018] Crankcase combination of the present invention is the same as prior art, comprises right crankcase 1 and left crankcase 2, is provided with fastening screw hole at left crankcase and right crankcase periphery, and fastening bolt passes through fastening screw hole and left crankshaft The case and the right crankcase are fixedly connected, and a gasket 3 is provided on the surface of the case to seal. In addition to preventing oil leakage after the combination of the left and right crankcases, the gasket also guides the direction of oil and gas, making it follow the set path.

[0019] The right crankcase 1 is provided with a right crankcase exhaust gas inlet 11, and the right crankcase exhaust gas inlet 11 communicates with the right crankcase exhaust gas passage 12. In the rear section of the right crankcase exhaust gas passage, a separation plate 13 is formed to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com