Structure for aviation gas turbine rotor supporting point ball bearing axial pre-load

An axial load, fulcrum ball technology, used in engine lubrication, engine components, turbine/propulsion lubrication, etc., can solve problems such as main bearing slippage, slippage damage, engine normal, reliable work threats, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

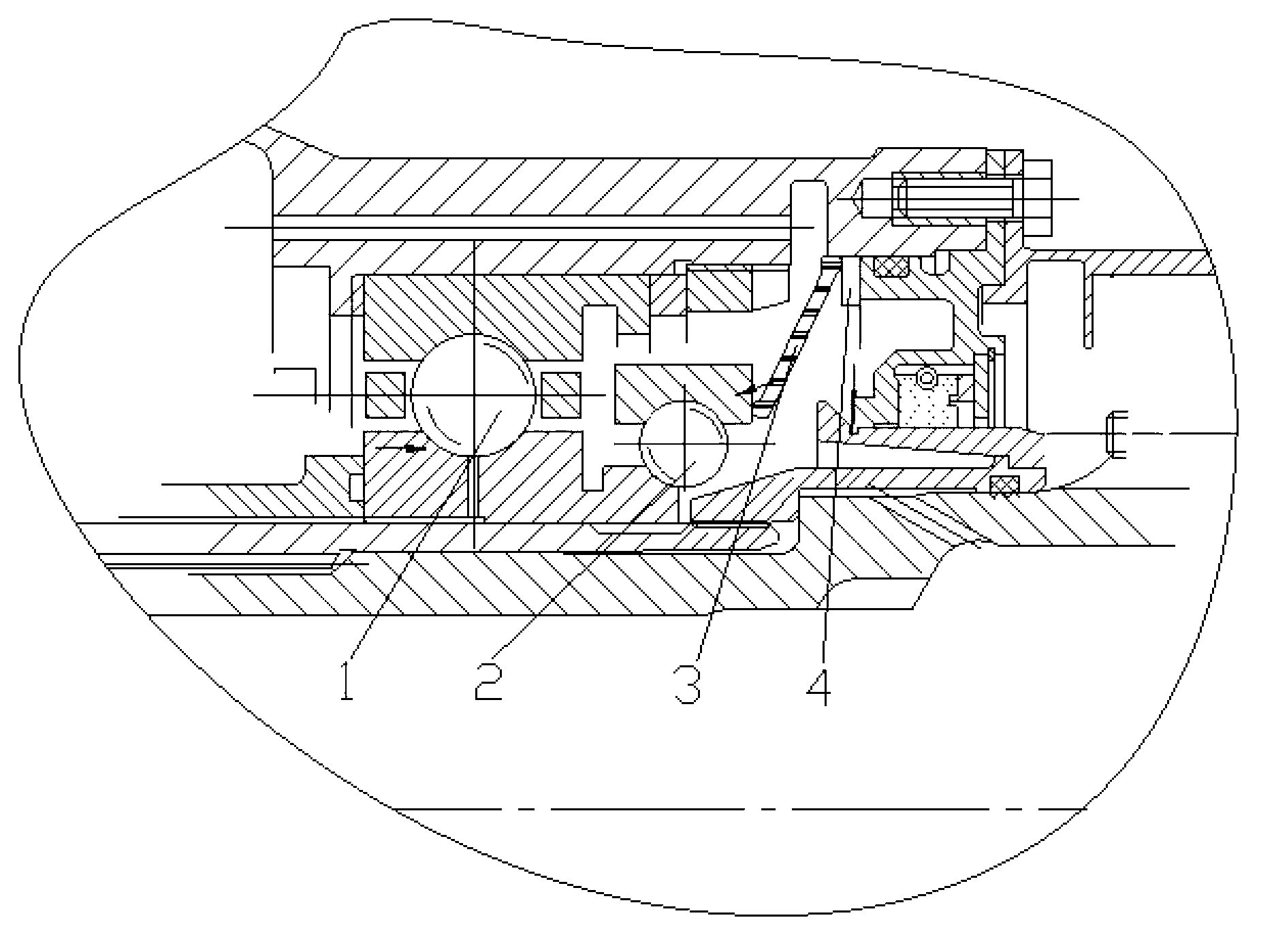

[0017] This embodiment provides a structure for pre-applying axial load of the fulcrum ball bearing of the aviation gas turbine rotor, which is characterized in that: the structure for pre-applying the axial load of the fulcrum ball bearing of the aviation gas turbine rotor includes the main Bearing 1, auxiliary bearing 2, disc spring 3, adjusting pad 4;

[0018] Among them: the auxiliary bearing 2 is fixed on the rotor of the gas turbine, and shares the inner ring of the bearing with the main bearing 1, the outer ring is fixed on the stator by means of floating or clearance fit, one end of the disc spring 3 is pressed against the end face of the outer ring of the auxiliary bearing 2, and the other end is It is tight against the end face of the adjustment pad 4, and the adjustment pad 4 is fixed on the stator.

[0019] In order to prevent the two ends of the disc spring from collapsing or wearing due to the large stress, the two ends of the disc yellow 3 need to be chamfered a...

Embodiment 2

[0024] This embodiment provides a structure for pre-applying axial load of the fulcrum ball bearing of the aviation gas turbine rotor, which is characterized in that: the structure for pre-applying the axial load of the fulcrum ball bearing of the aviation gas turbine rotor includes the main Bearing 1, auxiliary bearing 2, disc spring 3, adjusting pad 4;

[0025] Among them: the auxiliary bearing 2 is fixed on the rotor of the gas turbine, and shares the inner ring of the bearing with the main bearing 1, the outer ring is fixed on the stator by means of floating or clearance fit, one end of the disc spring 3 is pressed against the end face of the outer ring of the auxiliary bearing 2, and the other end is It is tight against the end face of the adjustment pad 4, and the adjustment pad 4 is fixed on the stator.

[0026] In order to prevent the two ends of the disc spring from collapsing or wearing due to the large stress, the two ends of the disc yellow 3 need to be chamfered a...

Embodiment 3

[0031] This embodiment provides a structure for pre-applying axial load of the fulcrum ball bearing of the aviation gas turbine rotor, which is characterized in that: the structure for pre-applying the axial load of the fulcrum ball bearing of the aviation gas turbine rotor includes the main Bearing 1, auxiliary bearing 2, disc spring 3, adjusting pad 4;

[0032] Among them: the auxiliary bearing 2 is fixed on the rotor of the gas turbine, and shares the inner ring of the bearing with the main bearing 1, the outer ring is fixed on the stator by means of floating or clearance fit, one end of the disc spring 3 is pressed against the end face of the outer ring of the auxiliary bearing 2, and the other end is It is tight against the end face of the adjustment pad 4, and the adjustment pad 4 is fixed on the stator.

[0033] In order to prevent the two ends of the disc spring from collapsing or wearing due to the large stress, the two ends of the disc yellow 3 need to be chamfered a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com