Arbitrary-tooth difference rolling transmission internal combustion engine

A technology of internal combustion engine and transmission mechanism, applied in the direction of transmission, machine/engine, mechanical equipment, etc., can solve the problems of shortening the life of the internal combustion engine, difficulty in processing, manufacturing, assembly, large mechanical wear, etc. Simple, consistent, compact results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

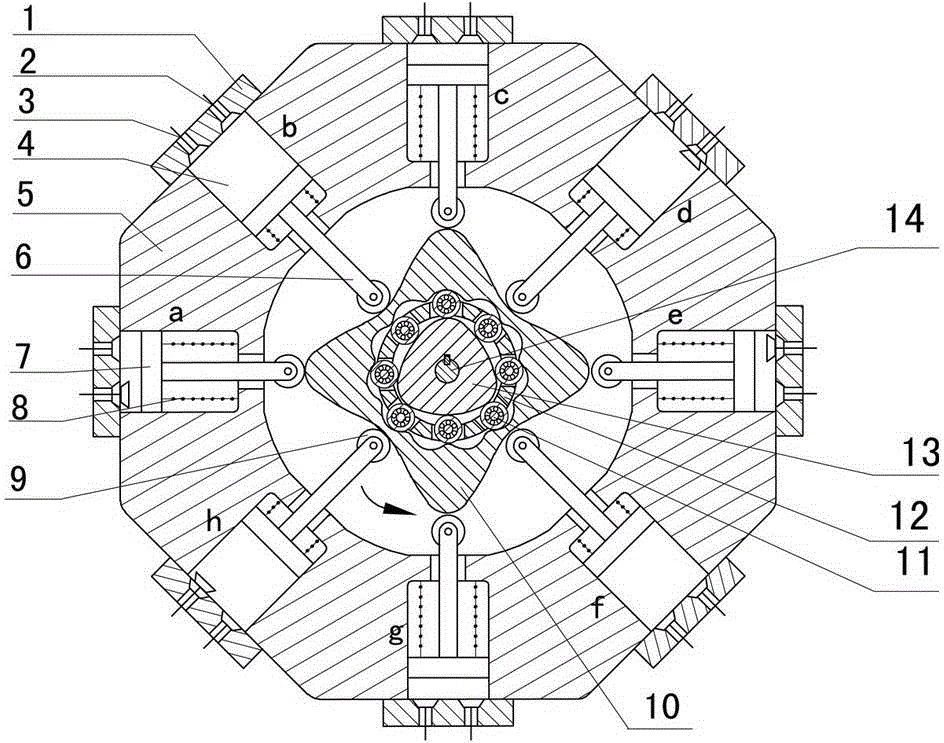

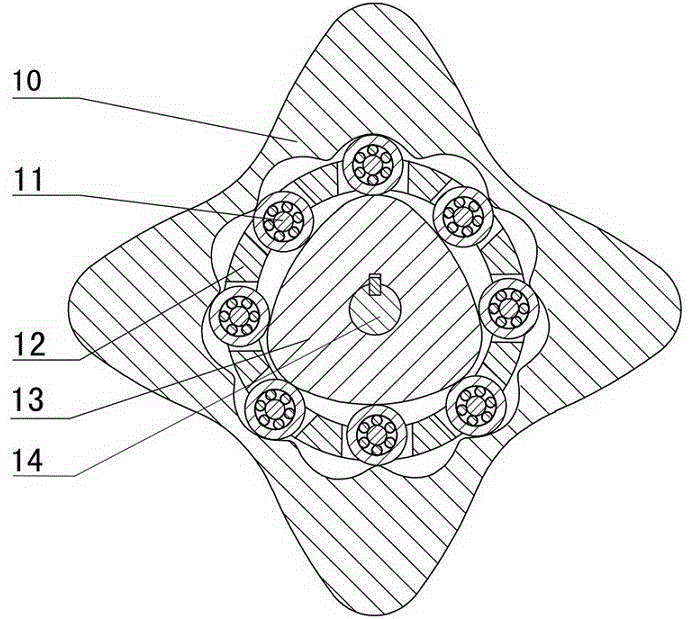

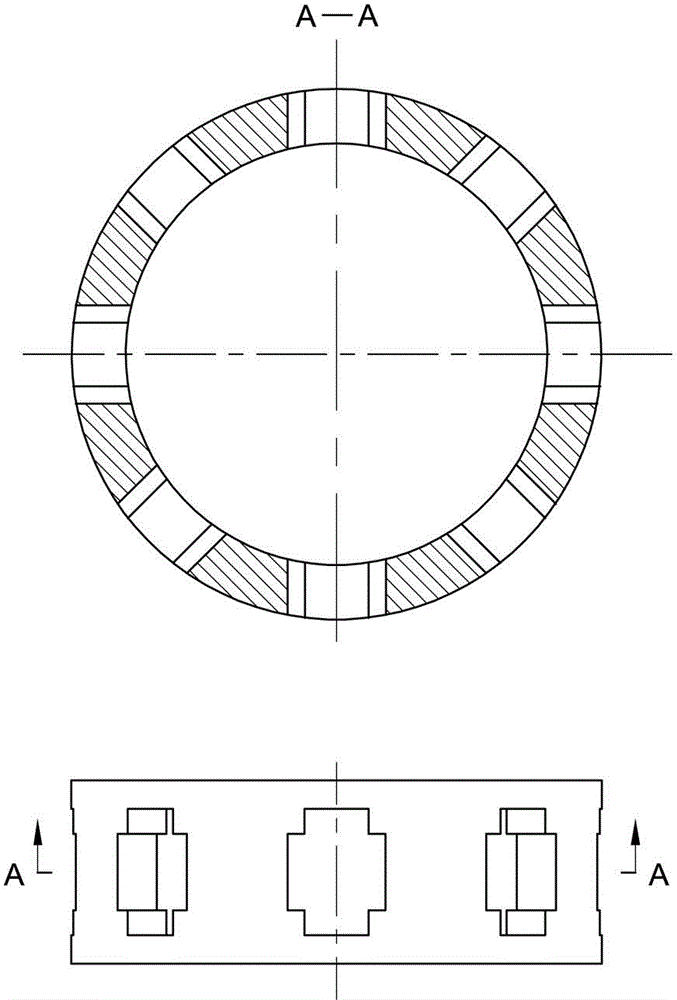

[0041] Figure 1 to Figure 5 The rolling transmission internal combustion engine with any number of tooth differences shown is composed of cylinder head (1), exhaust valve (2), intake valve (3), cylinder (4), cylinder block (5), push rod (6), piston (7), spring (8), roller (9), convex inner ring gear (10), rolling movable tooth (11), movable gear rack (12), multi-phase external cam (13), output shaft ( 14) Etc. composition. The eight cylinders (4) are evenly distributed around the convex inner ring gear (10) in an axially symmetrical manner, and the angle between two adjacent cylinders is 45°. There is a piston (7) in each cylinder (4), and one end of the push rod (6) is consolidated with the piston (7), and the other end is equipped with a roller (9), and the roller (9) makes the push rod ( 6) The connection with the convex inner ring gear (10) is a rolling friction connection. One end of the spring (8) is fixed on the bottom of the piston (7), and the other end is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com