Manufacture process of warp knitted fringe lace

A tassel lace and manufacturing technology, which is applied in warp knitting, textiles, papermaking, and decorative textiles, etc., can solve the problems of increased labor costs, loosening, and inability to protect the reverse weaving direction of lace, so as to reduce labor costs, The effect of speeding up the production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

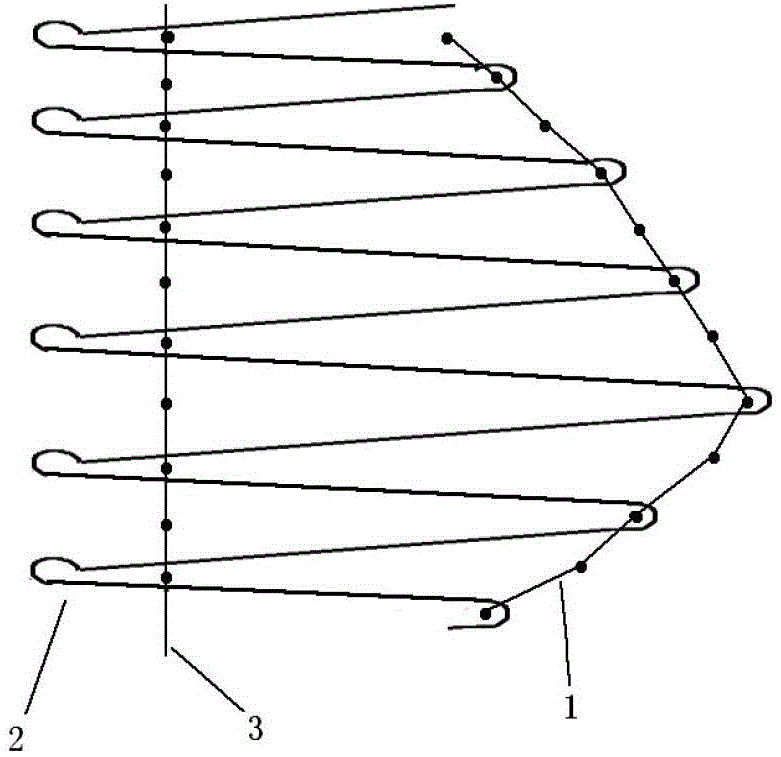

[0011] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0012] In order to achieve the above purpose in this embodiment, a technical solution proposed by the present invention is: a manufacturing process of warp-knitted tassel lace, including the steps of:

[0013] S1. Carry out patterns on the pressed yarn lace raw materials to make warp-knitted tassel lace. During the pattern pattern process, the patterns form loops while missing pads;

[0014] S2. Connect the missing side of the warp-knitted tassel lace with the cloth surface with water-soluble yarn;

[0015] S3. Dyeing the warp-knitted tassel lace, the dyeing step includes pretreatment, pre-setting treatment, dyeing treatment and setting treatment, wherein the pre-treatment is to decontaminate the warp-knitted tassel lace in water, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com