Totally enclosed less-chrome tanning circulation technique based on zirconium-aluminum-titanium cooperation tanning agent

A fully enclosed technology with tanning agents, applied in chemical treatment before tanning, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., to achieve good matching, The effect of reducing loose surface rate and good industrial production base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

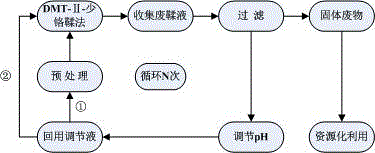

Image

Examples

Embodiment 1

[0026] (1) Pickling: Throw in the softened bare hide, add 50-60 parts of water into the drum, the inner temperature of the drum is normal temperature, add 7 parts of salt and 1 part of alum from the drum door, and continue to rotate for 10 minutes; measure the water in the bath. Salt concentration, the salt concentration is required to be ≥8°Bé; slowly add 0.5 parts of formic acid (1:10 diluted with water) and 0.8~0.9 parts of sulfuric acid (1:10 diluted with water) from the drum shaft during rotation, continuously rotate for 20 minutes, stop 10min, repeat 3~4 times, stop the drum overnight; rotate for 30min the next day; end point pH=2.8~3.0;

[0027] (2) Drain water with horses: Drain water with horses for more than 12 hours;

[0028] (3) Weighing: Accurate weighing is used as the basis for the calculation of the following processes;

[0029] (4) Pretreatment: Put acid bare hides in the drum, increase the weight of the hides to 120%, and the weight of the bare hides after t...

Embodiment 2

[0033] (1) Pickling: Throw in the softened bare hide, add 50-60 parts of water into the drum, the inner temperature of the drum is normal temperature, add 7 parts of salt and 1 part of alum from the drum door, and continue to rotate for 10 minutes; measure the water in the bath. Salt concentration, the salt concentration is required to be ≥8°Bé; slowly add 0.5 parts of formic acid (1:10 diluted with water) and 0.8~0.9 parts of sulfuric acid (1:10 diluted with water) from the drum shaft during rotation, continuously rotate for 20 minutes, stop 10min, repeat 3~4 times, stop the drum overnight; rotate for 30min the next day; end point pH=2.8~3.0;

[0034] (2) Drain water with horses: Drain water with horses for more than 12 hours;

[0035] (3) Weighing: Accurate weighing is used as the basis for the calculation of the following processes;

[0036] (4) Pretreatment: Put the acid bare hide in the drum, the weight of the hide increases to 120%, and the weight of the bare hide after...

Embodiment 3

[0040] (1) Pickling: Throw in the softened bare hide, add 50-60 parts of water into the drum, the inner temperature of the drum is normal temperature, add 7 parts of salt and 1 part of alum from the drum door, and continue to rotate for 10 minutes; measure the water in the bath. Salt concentration, the salt concentration is required to be ≥8°Bé; slowly add 0.5 parts of formic acid (1:10 diluted with water) and 0.8~0.9 parts of sulfuric acid (1:10 diluted with water) from the drum shaft during rotation, continuously rotate for 20 minutes, stop 10min, repeat 3~4 times, stop the drum overnight; rotate for 30min the next day; end point pH=2.8~3.0;

[0041] (2) Drain water with horses: Drain water with horses for more than 12 hours;

[0042] (3) Weighing: Accurate weighing is used as the basis for the calculation of the following processes;

[0043] (4) Pretreatment: put the acid bare hide in the drum, the weight of the hide increases to 120%, and the weight of the bare hide after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com