Preparation method for peak regulation of coal-based natural gas through methyl alcohol synthesis

A coal-to-natural gas and methanol-synthesizing technology, which is applied in the chemical industry and can solve the problems that coal gasification equipment cannot fully function and cannot produce other products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

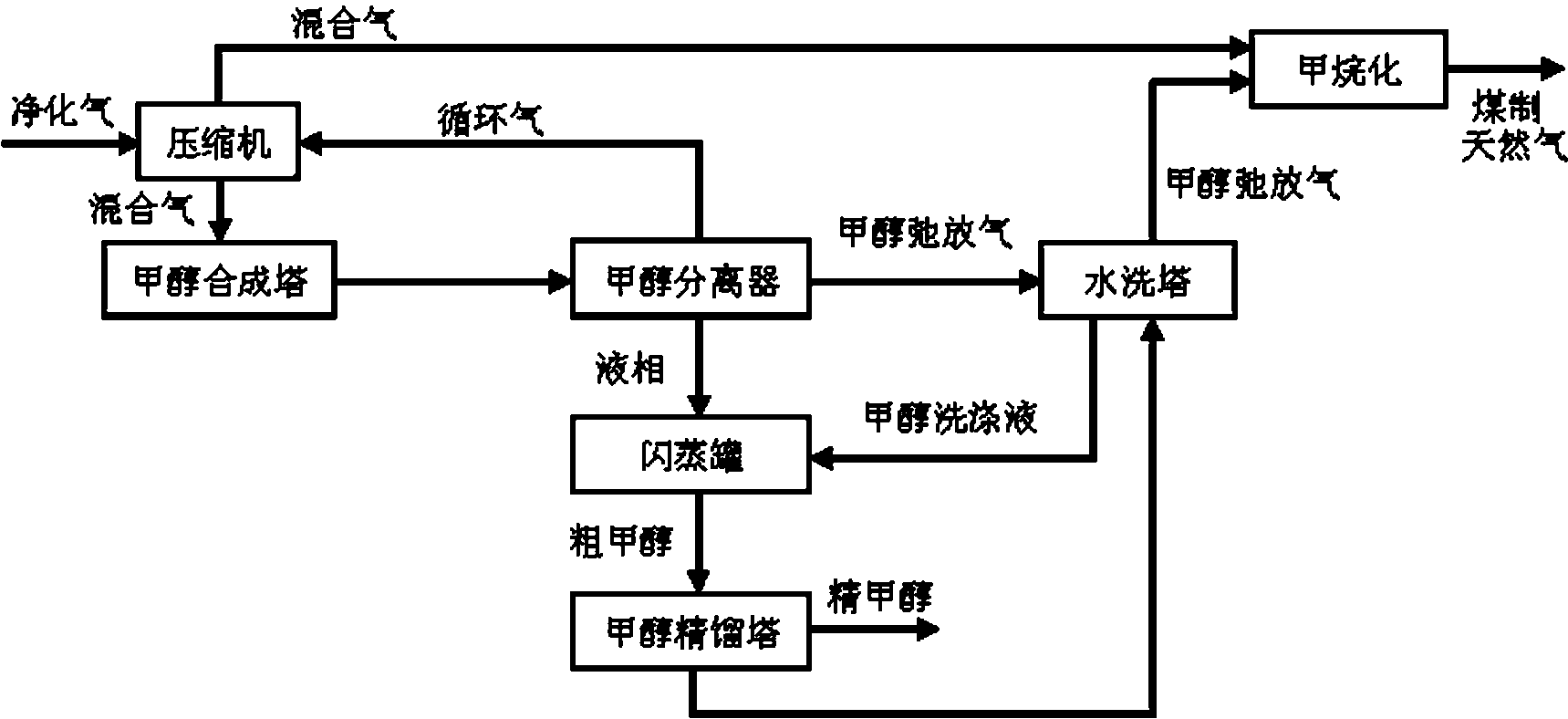

[0024] A preparation method for peak regulation of coal-to-natural gas by synthesizing methanol, comprising the following steps:

[0025] (1) The purified gas produced by coal gasification is sent to the heat exchanger for heat exchange through the compressor in the compression cycle section. The purified gas after heat exchange first enters the desulfurization reactor for desulfurization, and then enters the deoxidation reactor Deoxygenation to obtain synthesis gas.

[0026] (2) The cycle gas from the methanol separator is sent to the heat exchanger for heat exchange after being pressurized by the compressor in the compression cycle section.

[0027] or

[0028] The synthesis gas after deoxygenation in step (1) and the cycle gas after heat exchange in step (2) are mixed in the synthesis system and sent to the methanol synthesis tower for the reaction of preparing methanol.

[0029] (4) In the methanol synthesis tower, the mixture of synthesis gas and cycle gas passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com