Hydraulic four-point leveling method with accuracy less than 1 minute

A four-point leveling and hydraulic technology, applied in the direction of elastic suspension, suspension, transportation and packaging, etc., can solve problems such as no specific formula is given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

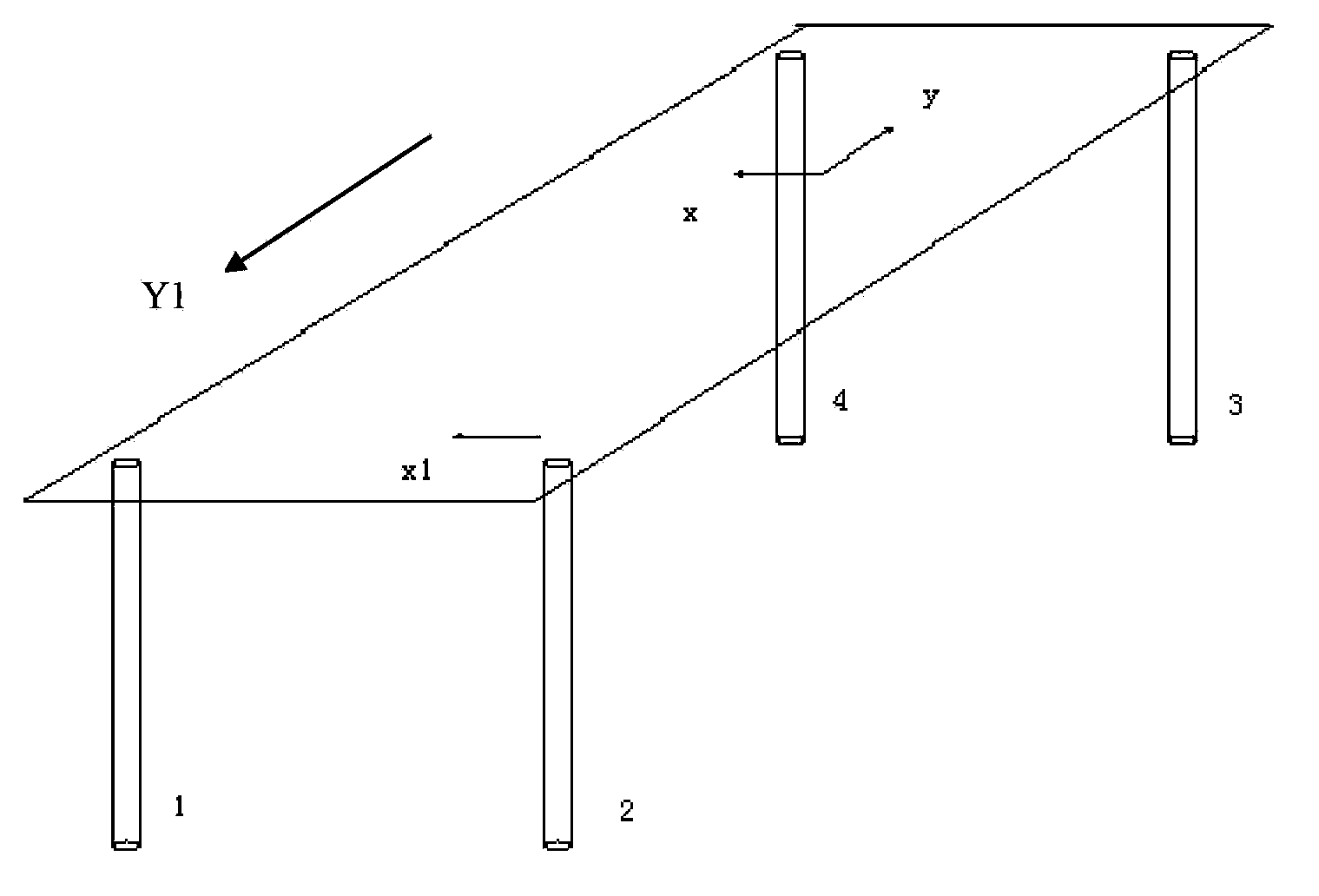

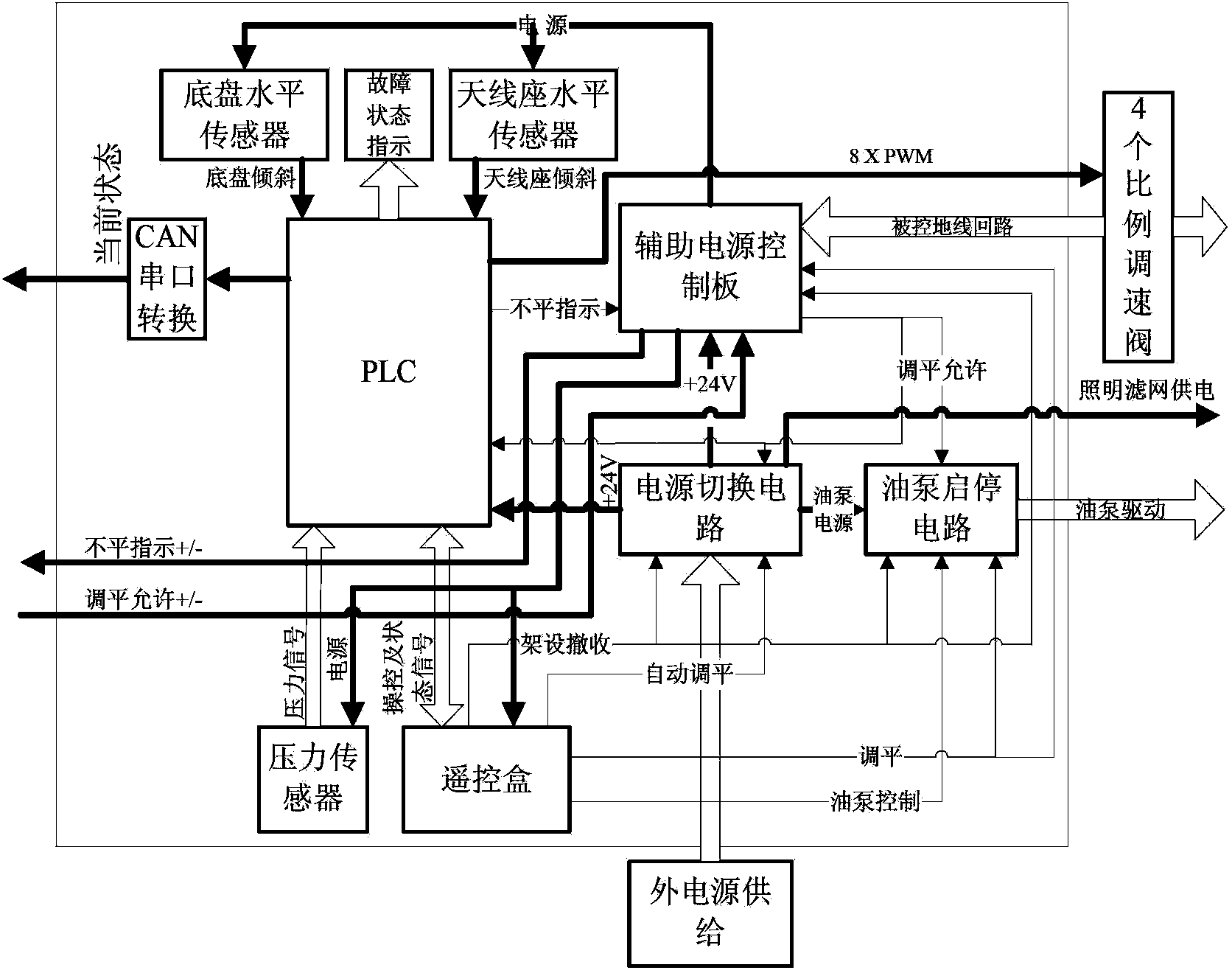

[0119] A hydraulic four-point leveling method with an accuracy less than 1′ when the rigidity of the vehicle body is insufficient, characterized in that: four-point hydraulic outriggers are installed on the main beam of the vehicle body, pressure sensors are installed in each outrigger, and antenna base level sensors Located at 1 / 4 of the rear leg direction from the geometric center of the car body, its transverse and longitudinal axes are respectively parallel to the transverse and longitudinal axes of the car body; a chassis level sensor is installed at the front end of the car body, and its transverse and longitudinal axes are parallel to the transverse and longitudinal axes of the car body; The car body is horizontally narrow and vertically long; the four-point hydraulic outrigger is controlled by a current control proportional valve; the polarity of the vertical axis of the antenna base level sensor and the chassis level sensor is positive at the front and high at the front...

Embodiment 2

[0149] A hydraulic four-point leveling method with an accuracy of less than 1′ when the rigidity of the vehicle body is satisfied. It is characterized in that: four-point hydraulic outriggers are installed on the vehicle body girder, a pressure sensor is installed in each outrigger, and an antenna base level sensor is installed. Located at 1 / 4 of the rear leg direction from the geometric center of the car body, its transverse and longitudinal axes are respectively parallel to the transverse and longitudinal axes of the car body; a chassis level sensor is installed at the front end of the car body, and its transverse and longitudinal axes are parallel to the transverse and longitudinal axes of the car body; The car body is horizontally narrow and vertically long; the four-point hydraulic outrigger is controlled by a current control proportional valve; the polarity of the vertical axis of the antenna base level sensor and the chassis level sensor is positive at the front and high ...

Embodiment 3

[0179] A hydraulic four-point leveling method with an accuracy of less than 1′ when the rigidity of the vehicle body is satisfied. It is characterized in that: four-point hydraulic outriggers are installed on the vehicle body girder, a pressure sensor is installed in each outrigger, and an antenna base level sensor is installed. Located at the geometric center of the car body, its transverse and longitudinal axes are respectively parallel to the transverse and longitudinal axes of the car body; a chassis level sensor is installed at the front end of the car body, and its transverse and longitudinal axes are parallel to the transverse and longitudinal axes of the car body; the car body is horizontally narrow and vertically long; the four-point hydraulic outrigger is controlled by a current control proportional valve; the polarity of the vertical axis of the antenna seat level sensor and the chassis level sensor is positive for low front and high rear, and negative for high front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com