Reaction device for SNCR (selective non-catalytic reduction) denitration system of circulating fluid bed

A circulating fluidized bed and reaction device technology, applied in chemical instruments and methods, dispersed particle separation, lighting and heating equipment, etc., can solve the problems of SNCR system inoperability, increased reductant escape, and reduced denitrification reaction speed, etc. Achieve normal operation, good escape, and reduce temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings: the description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the invention.

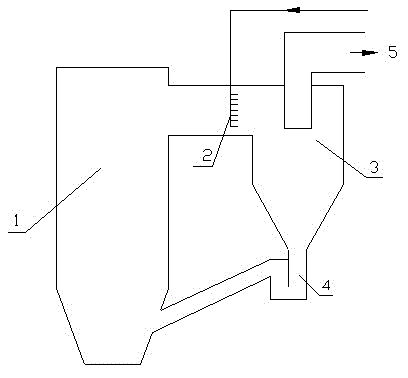

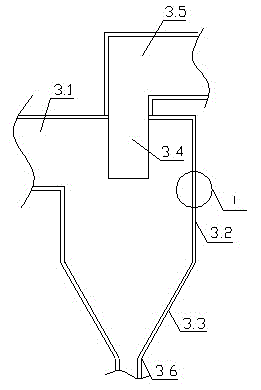

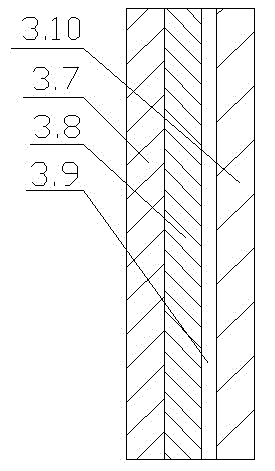

[0023] like figure 1 , figure 2 As shown, a reaction device for circulating fluidized bed SNCR denitrification system, including circulating fluidized bed boiler 1, horizontal flue, return device 4, tail flue 5, one side of circulating fluidized bed boiler 1 respectively It is connected with one end of the horizontal flue and the return device 4, the tail flue 5 is arranged at the other end of the horizontal flue, and the cyclone separator 3 is arranged between the other end of the horizontal flue and the return device 4, and the cyclone separator 3 Including air inlet 3.1, cylinder body 3.2, cone body 3.3, central cylinder 3.4, exhaust port 3.5, discharge port 3.6, the upper side of cylinder bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com