Automatic control fractionation device and application thereof

A fractionation device and control module technology, applied in the field of distillation, can solve the problems of difficult distillation temperature switching and separation, limited sample size, not enough to expand the sample, etc., to reduce visual fatigue, simple structure, simple and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

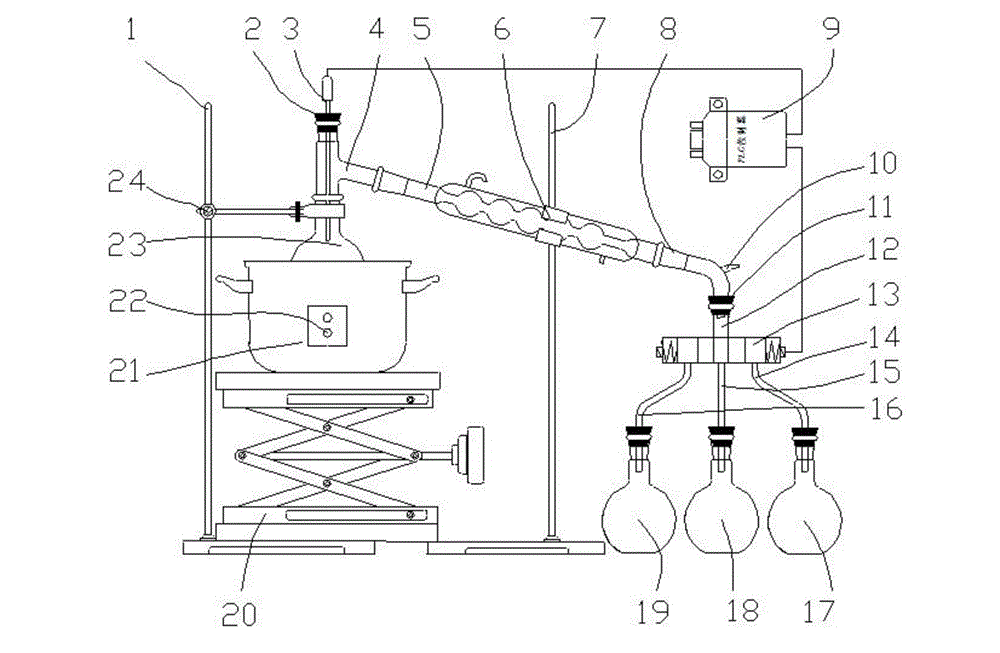

[0020] Automatically controlled fractionation device and application, including iron stand A1, rubber stopper A2, temperature sensor 3, three-way distillation head 4, condenser pipe 5, iron clip A6, iron stand B7, liquid pipe 8, PLC control module 9, pressure Balance hole 10, rubber plug B11, diversion tube 12, four-position three-way electric valve 13, diversion hose A14, diversion hose B15, diversion hose C16, liquid receiving bottle A17, liquid receiving bottle B18, connecting Liquid bottle C19, lifting table 20, temperature-controlled dry bath 21, temperature knob 22, single-mouth flask 23, iron clamp B24, characterized in that: the single-mouth flask 23 is fixed on the iron stand A1 by clamping the neck of the single-mouth flask 23 with iron clamp B24 , the belly of the single-necked flask 23 is placed in the temperature-controlled dry bath 21, the mouth of the single-necked flask 23 is connected to the lower port of the three-way distillation head 4, the upper port of the...

Embodiment 2

[0023] The fractionation device of automatic control and the operating steps of application are characterized in that:

[0024] Step 1: write the temperature control conditions required for the materials to be distilled and separated into the PLC control module 9;

[0025] Step 2: Pack the feed liquid that needs to be fractionated into the single-necked flask 23, connect and install the automatically controlled fractionation device according to the method described in Embodiment 1, and connect the cooling water of the condensation pipe 5;

[0026] Step 3: Turn on the power, turn on the temperature-controlled dry bath 21 to heat the feed liquid in the single-mouth flask 23 until the first boiling point component is distilled out, and through condensation, the liquid connection pipe 8, the draft pipe 12, and the four-position The three-way electric valve 13 and the diversion hose A14 enter the liquid receiving bottle A17;

[0027] Step 3: When the first low-temperature componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com