Clamping type fire-fighting pipe piece

A fire-fighting pipe, snap-fit technology, applied in the direction of pipe/pipe joint/fitting, passing element, sleeve/socket connection, etc., can solve the problems of low installation efficiency, long construction period, high cost, etc., to save time and guarantee Product quality, the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

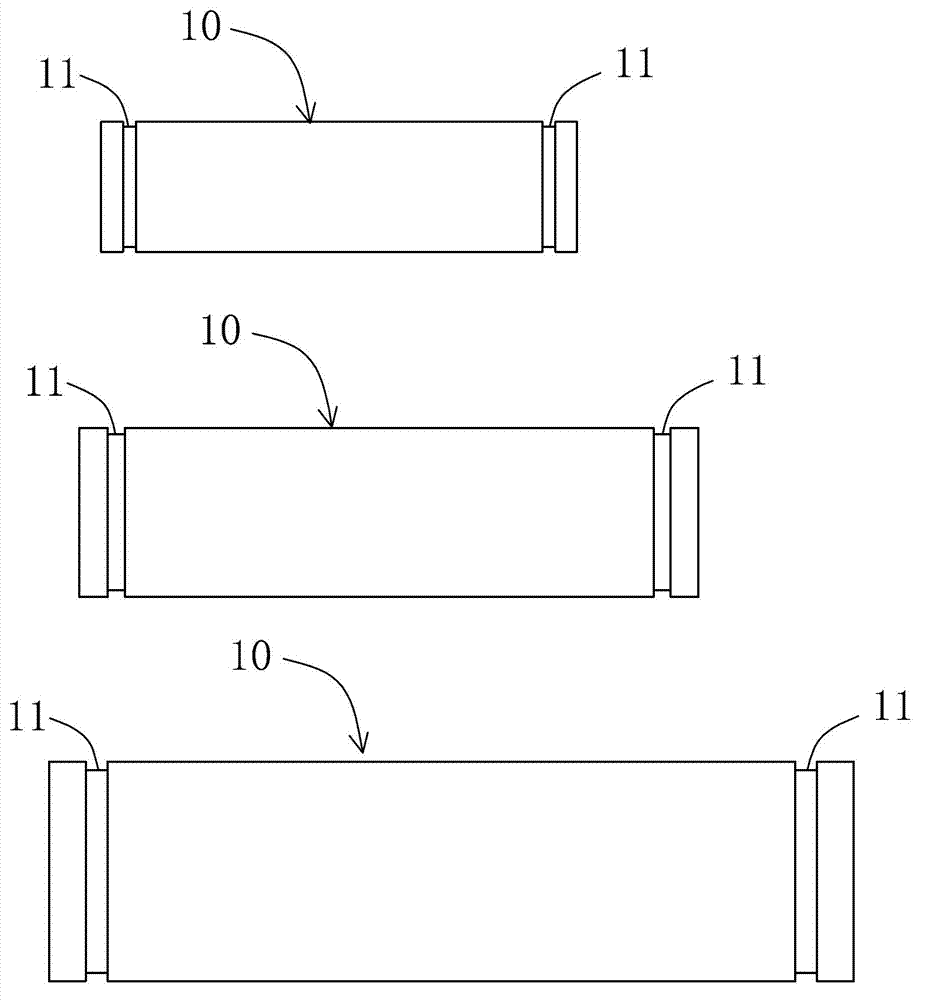

[0016] refer to figure 1 , The clip-on fire-fighting pipe fitting of the present invention is a fire-fighting pipe fitting of different specifications and sizes manufactured through large-scale production in the factory, and can be directly installed and used without processing at the construction site.

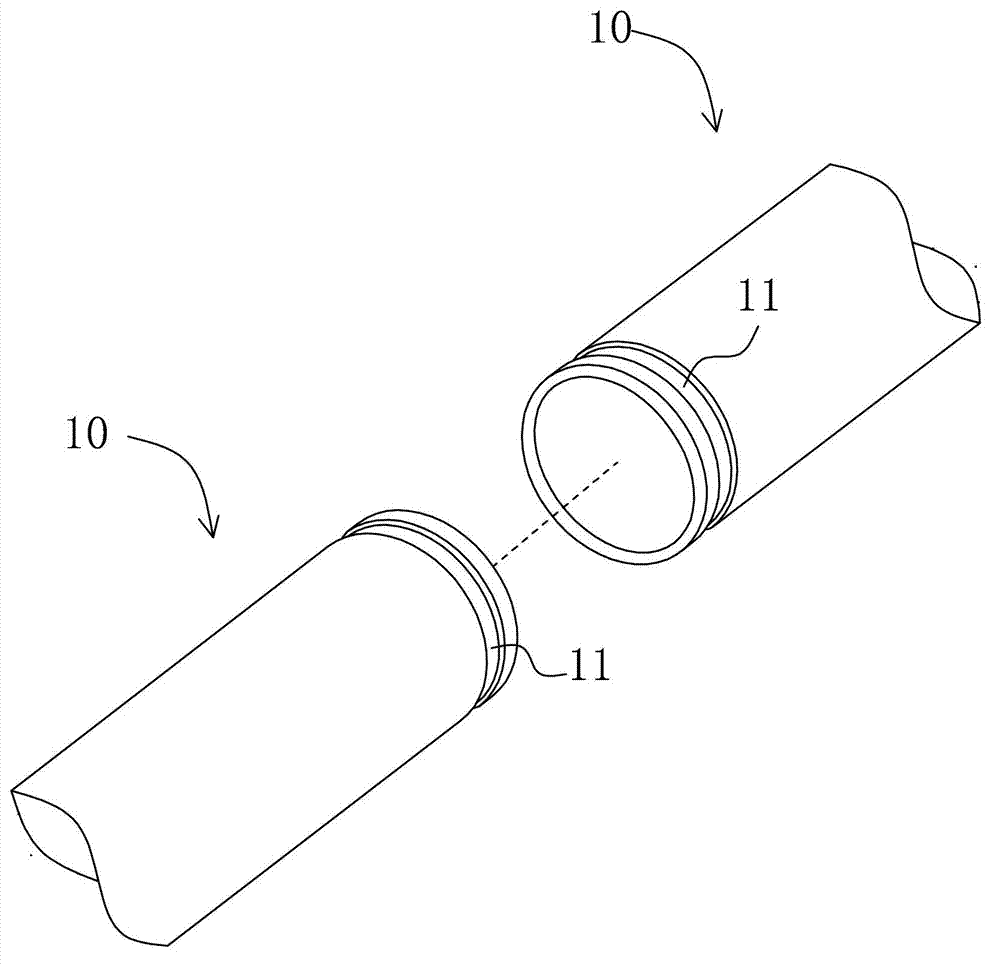

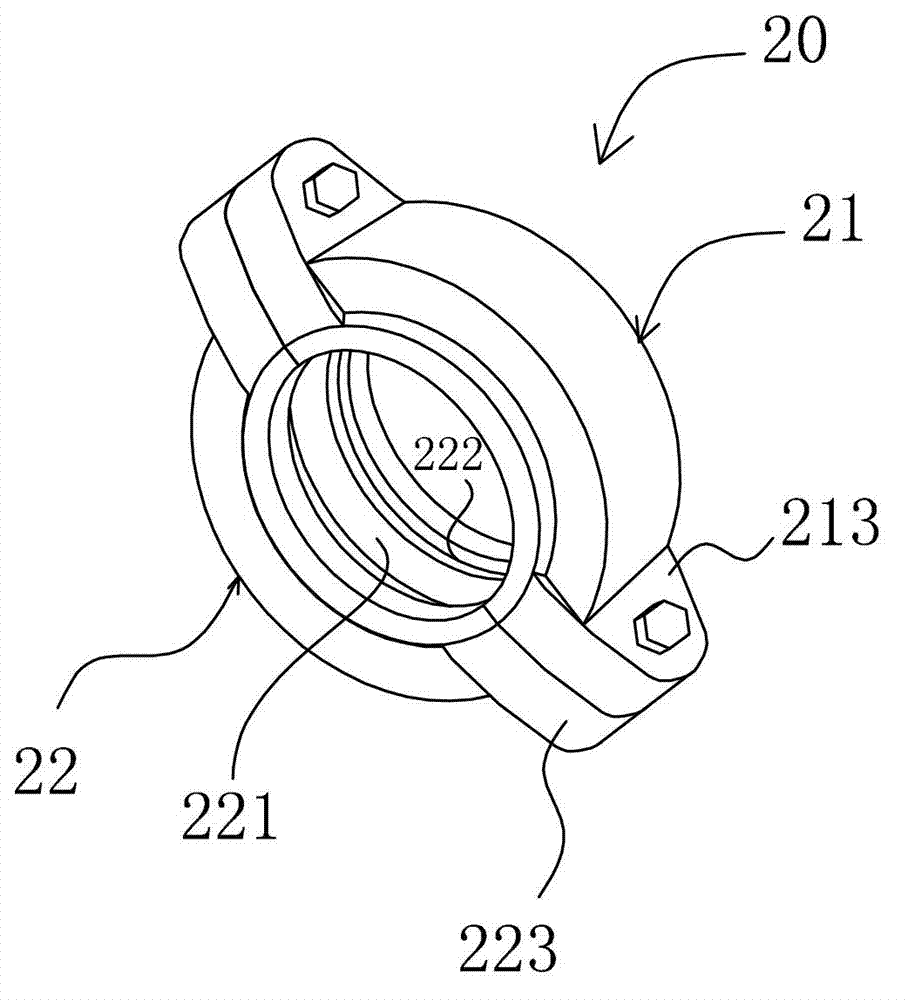

[0017] exist figure 2 In the shown embodiment, when processing the fire-fighting pipe 10, steel pipes of different diameters are taken and cut into pipes of different sizes. For example, steel pipes of different diameters can be cut into pipes with a length difference of 1 cm. On the outer peripheral surface of the two ends of each section of steel pipe near the end surface, a circumferentially concave annular clamping groove 11 is respectively processed. 20 connected. Galvanized and sprayed with antirust paint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com