Floating bulb type cut-off valve

A technology of floating ball head and stop valve, which is applied in the direction of lifting valve, valve device, engine components, etc., can solve the problems of valve leakage, wear of stop valve sealing surface, etc., and achieve the effect of improving sealing reliability and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

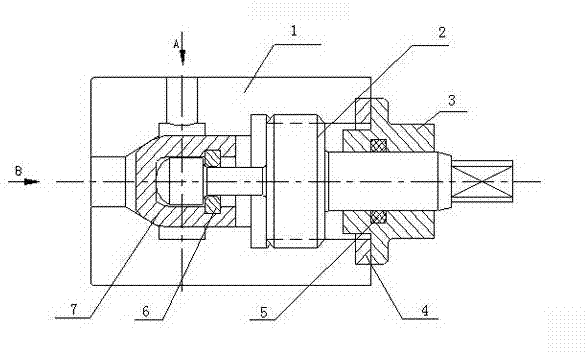

[0022] The sealing cap 7 can be arranged in the accommodating space of the housing 1, and the screw rod 2 is movably connected with the sealing cap 7. The sealing cap 7 can be provided with a groove. The screw head of the screw 2 can just be accommodated in the groove, and the head of the screw 2 is movably connected with the screw through a baffle 6 . The screw rod 2 transmits the axial force to the sealing cap; the baffle plate can be clamped on the connecting arm arranged in the accommodation groove of the sealing cap, such as figure 1 , the screw head can be a ball head structure; the sealing cap can be a floating type.

[0023] like figure 1 , the floating ball stop valve can also include a threaded sleeve 3, which is connected to the screw 2, and the threaded sleeve 3 is arranged outside the housing 1; and the globe valve also includes a sealing ring 4, so The sealing ring is arranged on the edge part of the housing; the connection between the screw sleeve and the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com