Matched improved structure for impeller and guide vane body bodies of axial flow pump

A technology of guide vanes and axial flow pumps, which is applied to parts, pumps, and pump elements of pumping devices for elastic fluids. It can solve the problems of low load pressure and inability to generate flow, and achieve the effect of increasing load pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

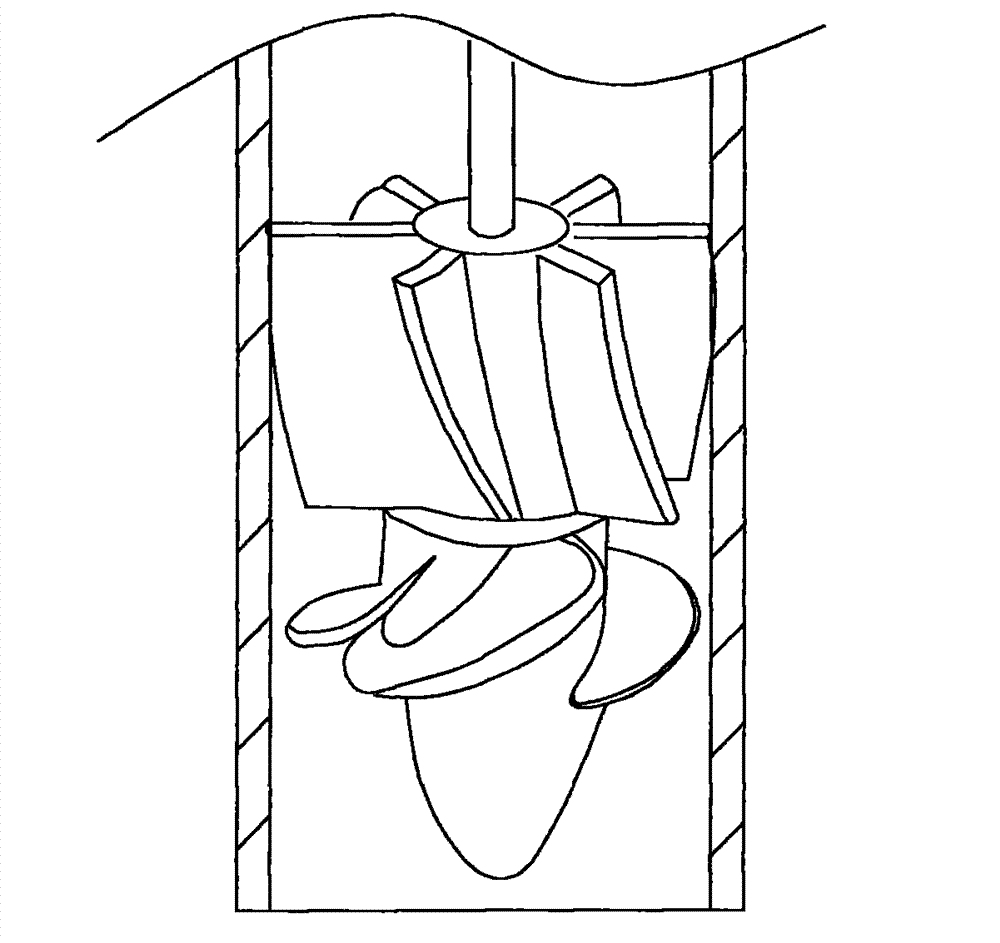

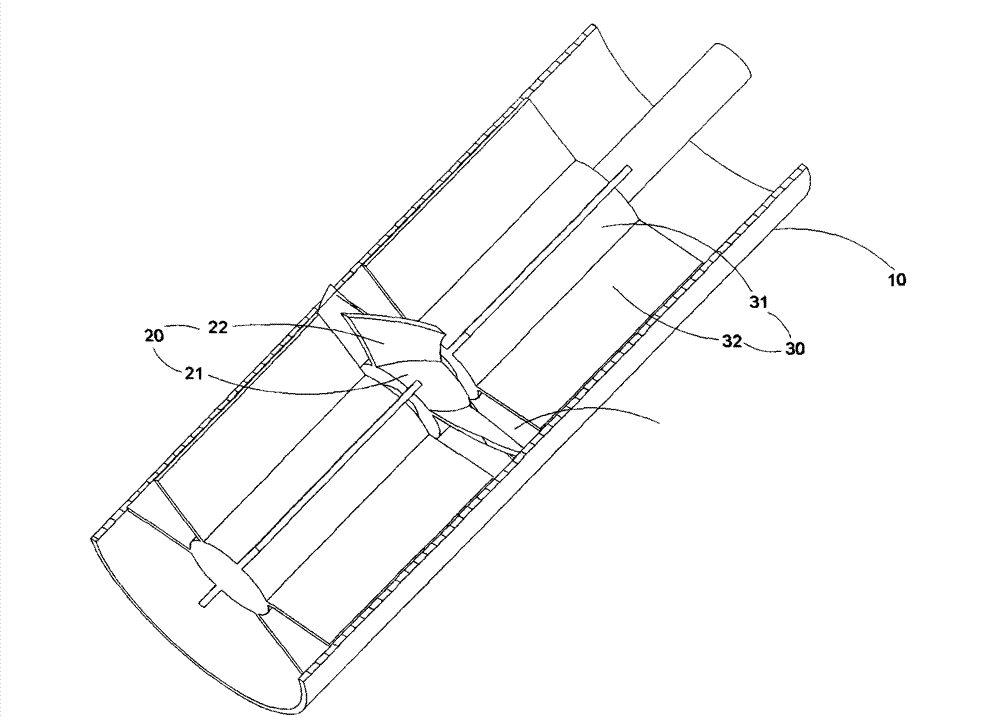

[0022] Such as Figure 2 to Figure 4 Shown is a preferred specific implementation example of the present invention, an improved supporting structure of the impeller and guide vane body of an axial flow pump, such as figure 1 As shown, it includes a casing 10, an impeller 20 and two vane bodies 30, wherein the impeller 20 is placed in the casing 10, and one vane body 30 is placed in the casing 10 above the impeller 20, The other vane body 30 is correspondingly disposed in the casing 10 below the vane body 20 .

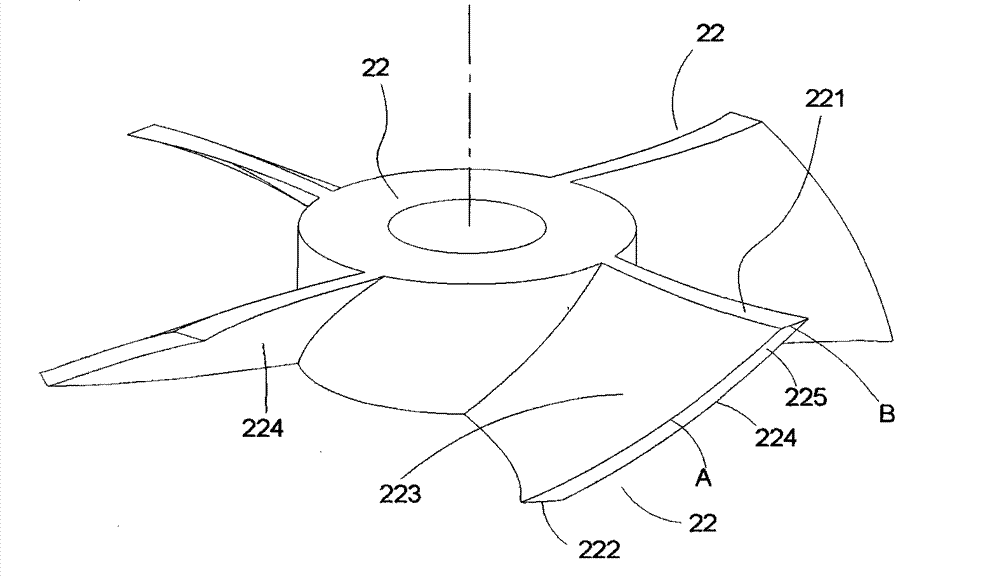

[0023] Such as figure 2 As shown, the impeller 20 includes a hub 21 and several blades 22 equidistantly distributed around the hub 21, wherein each blade 22 has an upper end surface 221, a lower end surface 222, a pressure surface 223, a rear end surface 224 and a front end surface 225, Wherein, the pressure surface 223 and the rear end surface 224 are parallel to each other, and any point on the front end surface 225 is equal to the axial center displacement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com