Connecting device for connecting concrete tower barrel and steel tower barrel

A connection device and concrete technology, which is applied in the field of connection devices connecting concrete towers and steel towers, can solve the problems of complex force mechanism and failure form at the connection, uneven force on concrete towers, and low safety. Achieve the effects of simple force, avoid uneven force, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

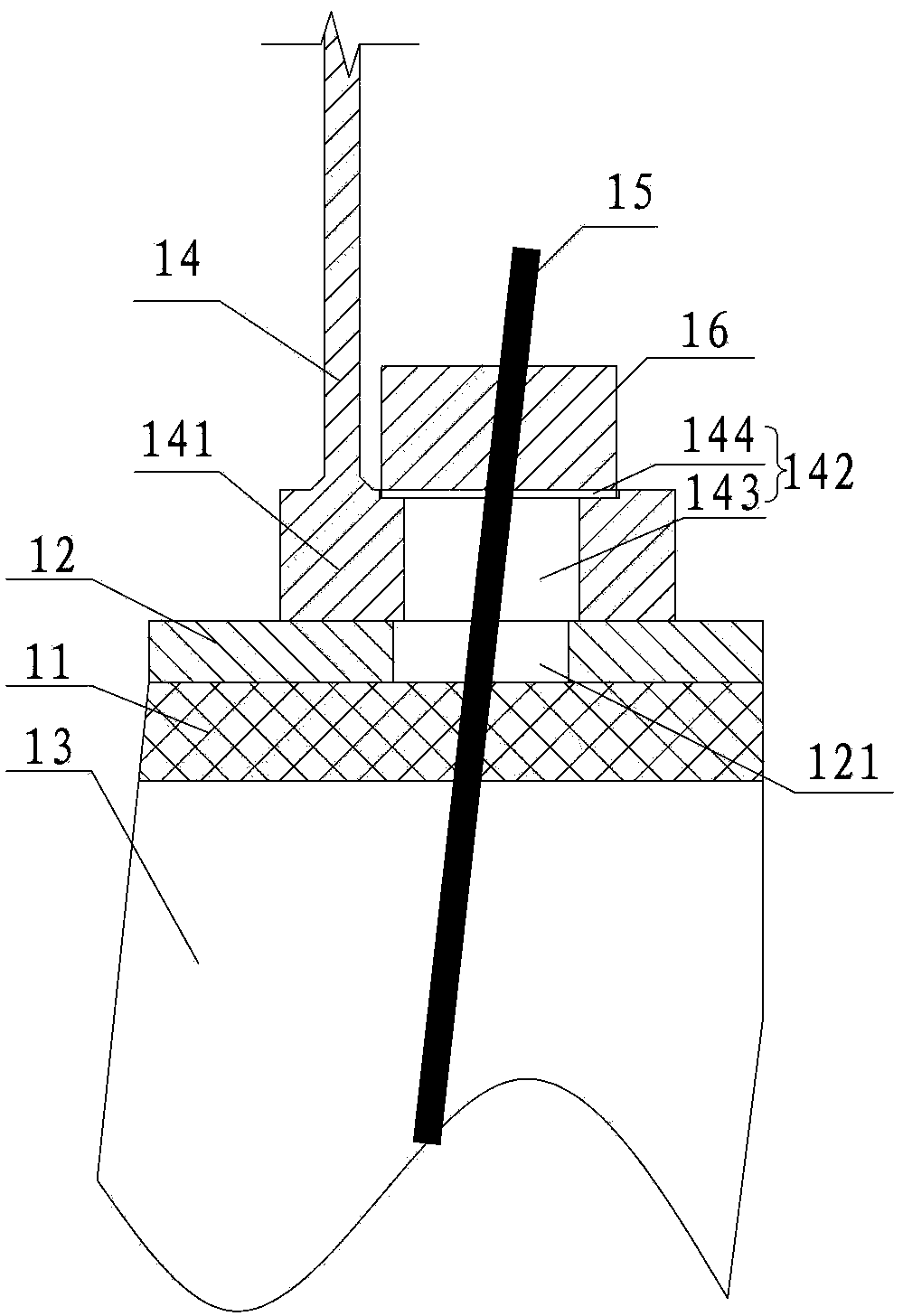

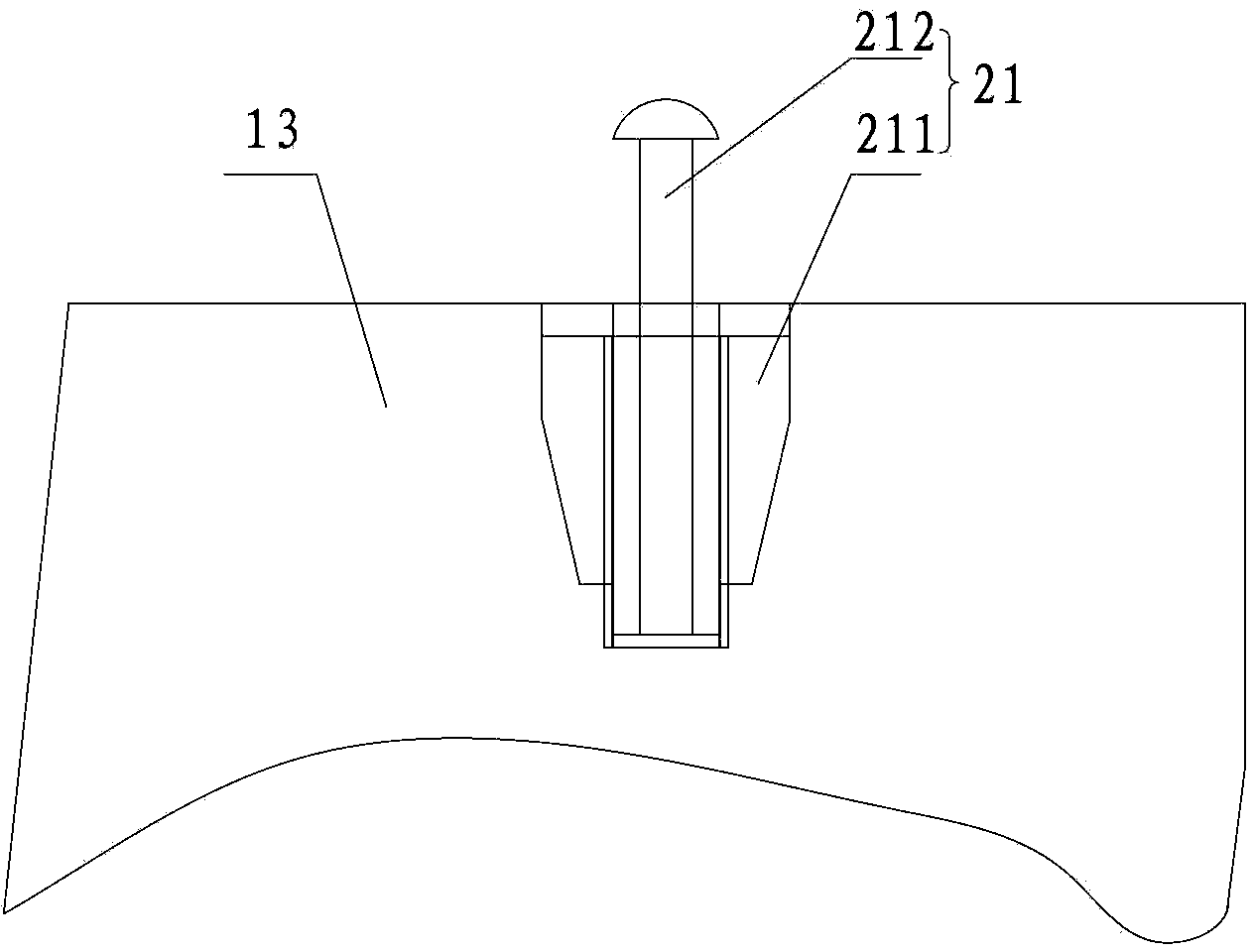

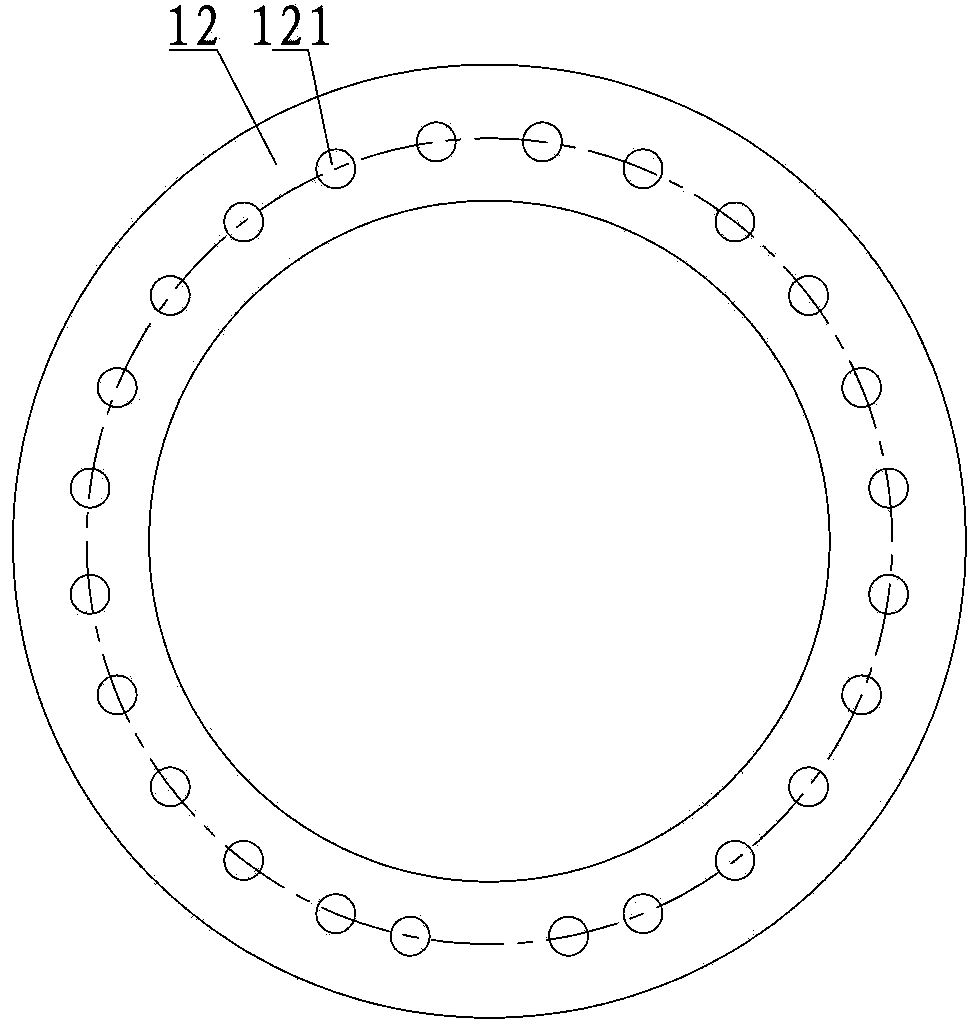

[0024] The embodiment of the present invention provides a connecting device for connecting a concrete tower tube and a steel tower tube, such as figure 1 As shown, it includes a grouting layer 11 and a steel backing plate 12. The steel backing plate 12 is placed horizontally on the top surface of the concrete tower 13 and the steel backing plate 12 covers the top surface of the concrete tower 13; the grouting layer 11 is filled on the steel cushion The plate 12 and the top surface of the concrete tower tube 13 are used to connect the steel backing plate 12 and the concrete tower tube 13; wherein the top surface of the steel backing plate 12 is attached to the bottom surface of the bottom flange 141 of the steel tower tube 14 .

[0025] In the connecting device for connecting the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com