Plate plug method capable of realizing vibratory compaction

A plug-in and compact technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of uneven settlement of the site, large loss of tamping energy, and poor treatment effect, so as to enhance the anti-liquefaction ability and improve The effect of compactness and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

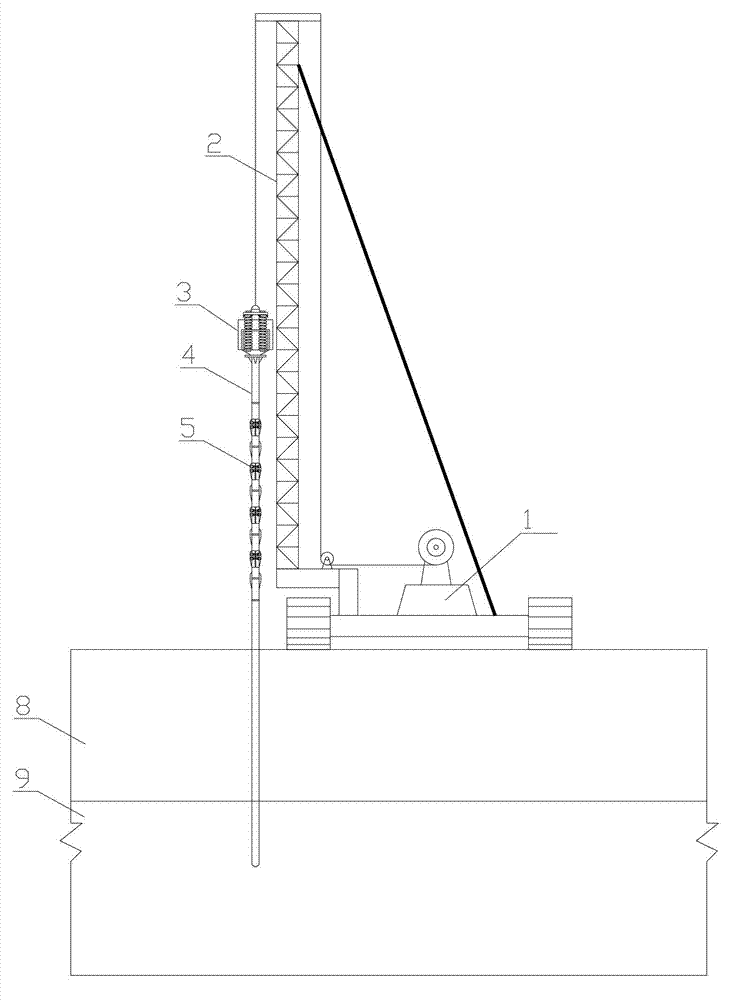

[0028] Follow the steps below for a vibration-tight gate operation.

[0029] 1 On-site cleaning: Before the construction of the plug-in board, the construction site should be cleaned up to ensure that the site is flat and there are no obstacles that affect the on-site measurement and setting out.

[0030] 2 Measurement and stakeout: After the site is cleared, measure and stake out according to the point coordinates and pile spacing given by the design.

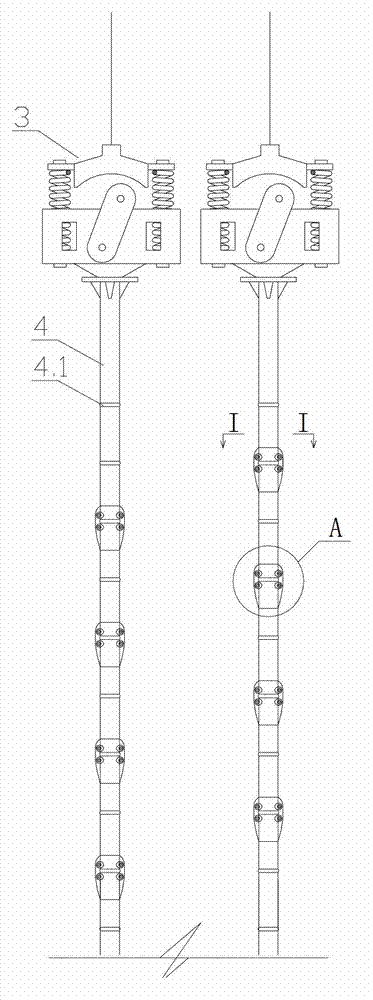

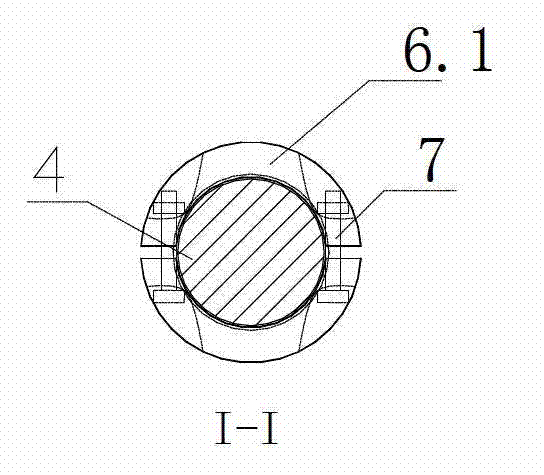

[0031] 3 Equipment commissioning: on-site commissioning of the crawler-type double-pipe vibrating plate inserting machine, positioning of the machine, according to the design requirements for the spacing of the drainage plate piles and the dynamic characteristics of the on-site powder and fine sand foundation, the structure of the pile pipe wall is modified, and the appropriate diameter of the pile pipe is selected ( 110~180mm), select the vibrator, determine the vibration frequency (24Hz) and the excitation force (the maximum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com