Metal ion / starch aggregate and preparation method thereof

A technology of metal ions and aggregates, which is applied in the field of metal ions/starch aggregates, can solve problems such as few researches, and achieve the effects of simple process, low energy consumption and good feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of starch solution: Add modified starch into distilled water, heat and dissolve at 95°C for 10 minutes, and prepare a solution with a mass fraction of 0.01%. After cooling to 25°C, put it into the refrigerator at 4°C for 12 hours to freeze, then centrifuge at 6000 rpm for 10 minutes to remove the precipitate, repeat this process 3 times, remove the gel particles, and obtain the starch solution.

[0034] (2) Preparation of metal ion solution: Weigh copper chloride and prepare a copper chloride solution with a molar concentration of 0.5M with deionized water for later use.

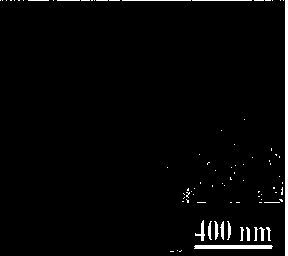

[0035] (3) Cu 2+ / Preparation of starch spherical aggregates: Take 20mL of the starch solution prepared in step (1), and add 0.8mL of copper chloride solution with a molar concentration of 0.5M to the starch solution under stirring at 80°C, and heat at 80°C Heated and stirred for 0.5h, a light blue transparent solution was obtained, and Cu 2+ / Starch spherical aggregates, the prepare...

Embodiment 2

[0037] (1) Preparation of starch solution: Add acidified starch into distilled water, heat and dissolve at 100°C for 30 minutes, and prepare a solution with a mass fraction of 0.5%. After cooling to 30°C, put it in the refrigerator to freeze at 8°C for 24 hours, then centrifuge at 4000 rpm for 15 minutes to remove the precipitate, and repeat this 5 times to remove the gel particles to obtain the starch solution.

[0038] (2) Preparation of metal ion solution: Weigh ferric chloride and prepare a ferric chloride solution with a molar concentration of 0.5M with deionized water for later use.

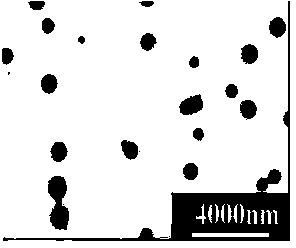

[0039] (3) Preparation of Fe3+ / starch linear aggregates: Take 18.4mL starch solution with a mass fraction of 0.5%, add 0.8mL ferric chloride solution with a molar concentration of 0.5M to the starch solution under stirring conditions at 50°C , heated and stirred at 50°C for 1 h, a brownish-red transparent solution was obtained, and Fe 3+ / Starch linear aggregates, the prepared solution was...

Embodiment 3

[0041] (1) Preparation of starch solution: Add alkalized starch into distilled water, heat and dissolve at 80°C for 1.5h, and prepare a solution with a mass fraction of 0.25%. After cooling to 20°C, put it in the refrigerator to freeze at 4°C for 16 hours, then centrifuge at 3500 rpm for 30 minutes to remove the precipitate, and repeat this 4 times to remove the gel particles, and then the starch solution is obtained.

[0042] (2) Preparation of metal ion solution: Weigh ferric chloride and prepare a solution with a molar concentration of 0.1M with deionized water for later use.

[0043] (3) Fe 3+ / Preparation of starch linear aggregates: take 18.4mL of starch solution with a mass fraction of 0.25%, and add 0.8mL of ferric chloride solution with a molar concentration of 0.1M to the starch solution under stirring conditions at 60°C, and heat at 60°C Heated and stirred for 30h, a brownish-red transparent solution was obtained, and Fe 3+ / Starch linear aggregates, the prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com