Linkage mechanism of side moulds and bottom mould of bottle blowing machine

A technology of linkage mechanism and blowing machine, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of difficult maintenance, large maintenance costs, and increased cost input, and achieves enhanced matching accuracy, reduced equipment volume, and effective The effect of using space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

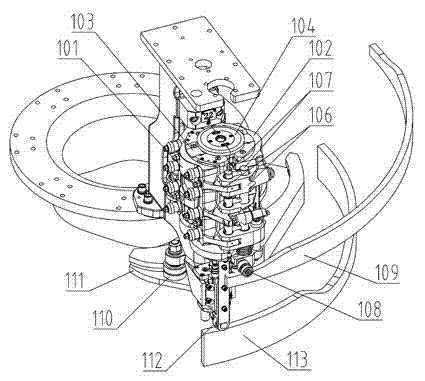

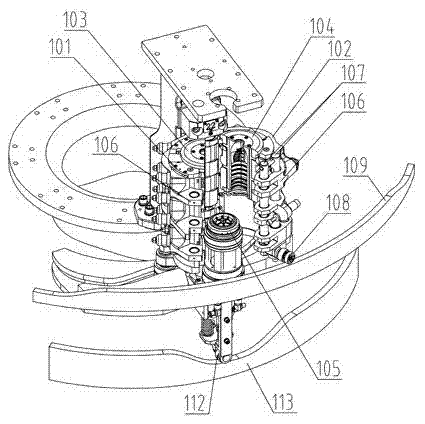

[0014] Embodiment one, such as image 3 , 4 , 5 shown.

[0015] The linkage mechanism of the bottle blowing machine side mold and the bottom mold according to the present invention includes a mold frame bracket 1, an opening and closing connecting rod 2 that drives the opening and closing of the bottle blowing machine side mold, and a bottom mold bracket 3 that drives the bottom mold of the bottle blowing machine to lift. , there is a linkage linkage device connecting the opening and closing linkage 2 and the bottom mold bracket 3, the opening and closing linkage 2 drives the movement of the linkage linkage while driving the mold to open and close, and then the linkage linkage drives the bottom mold bracket 3 to lift; A guide rail seat 5 is arranged on the formwork bracket 1, and a slide rail 4 sliding in the guide rail seat 5 is connected to the bottom mold support 3; the linkage link device includes a fixed link 6 fixed on the opening and closing link 2 , the crank 7 hinge...

Embodiment 2

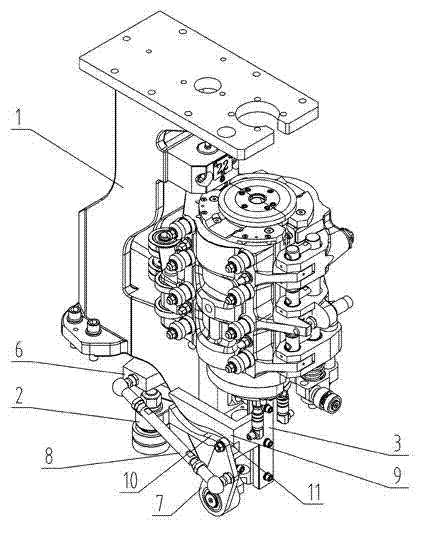

[0017] Embodiment two, such as Figure 6 , 7 , 8 shown.

[0018] The linkage connecting rod device includes a fixed connecting rod 6 fixed on the opening and closing connecting rod 2, a curved groove angle plate 91 hinged on the formwork bracket 1, and the fixed connecting rod 6 and the curved groove angle plate 91 pass through the bearing connecting rod The two ends of 8 are connected, the fixed connecting rod 6 is driven by the opening and closing connecting rod 2 and drives the bearing connecting rod 8 and the curved groove angle plate 91 to move in turn; the curved groove angle plate 91 has a curved groove 92, and the bottom mold support 3 The roller 11 that can roll in the curved groove 92 is arranged, and when the curved groove angle plate 91 rotates, the curved groove 92 applies a vertical force to the roller 11, and then drives the roller 11 and the bottom mold support 3 to move. All the other are the same as the first embodiment.

[0019] When moving, the opening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com