Special pressure filter tank for filter press

A pressure filter tank and filter press technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of high feeding pump power, slow filtration speed, low efficiency, etc., to reduce energy consumption and increase pressure The effect of filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

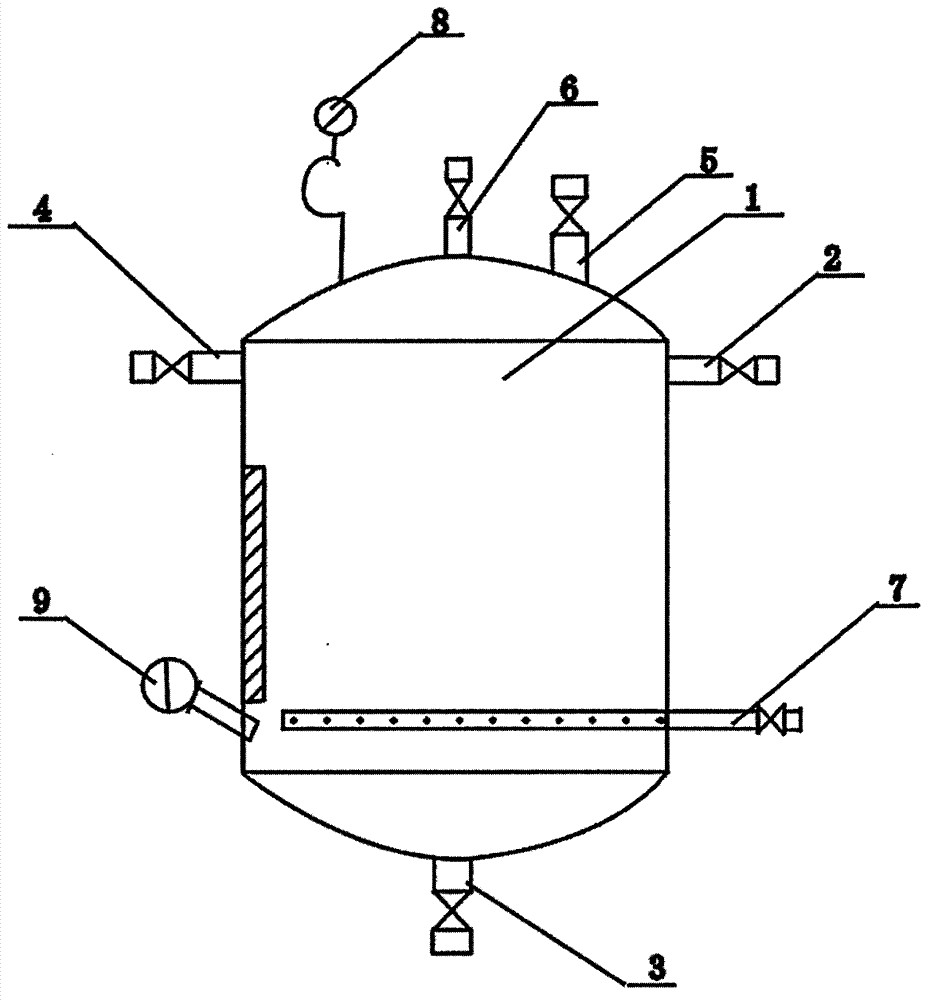

[0009] Referring to the accompanying drawings, the pressure filter tank dedicated to the filter press of the present invention includes a tank body 1, the tank body 1 is a sealed tank body made of high-quality stainless steel or carbon steel material, and a tank body with a tank body is installed on the top of the tank body 1. An exhaust pipe 5 with a valve, a compressed air inlet pipe 6 with a valve and a pressure gauge 8 connected to the inner cavity of the body 1; a feed pipe 2 with a valve connected to the inner cavity of the tank body 1 is installed on the upper part of the tank body 1; Overflow pipe 4 with a valve; a steam heating pipe 7 with a valve is installed at the bottom of the tank body 1, the steam heating pipe 7 is directly connected to the inside of the tank body, and 80 steam heating pipes 7 are evenly distributed in the inside of the tank body steam injection hole, the diameter of the steam injection hole is 3mm, and a temperature gauge 9 communicating with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com