Gear pump

A technology of gear pumps and gears, applied to pumps, pump components, rotary piston pumps, etc., can solve problems such as increased manufacturing costs, and achieve the effects of small volume flow and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

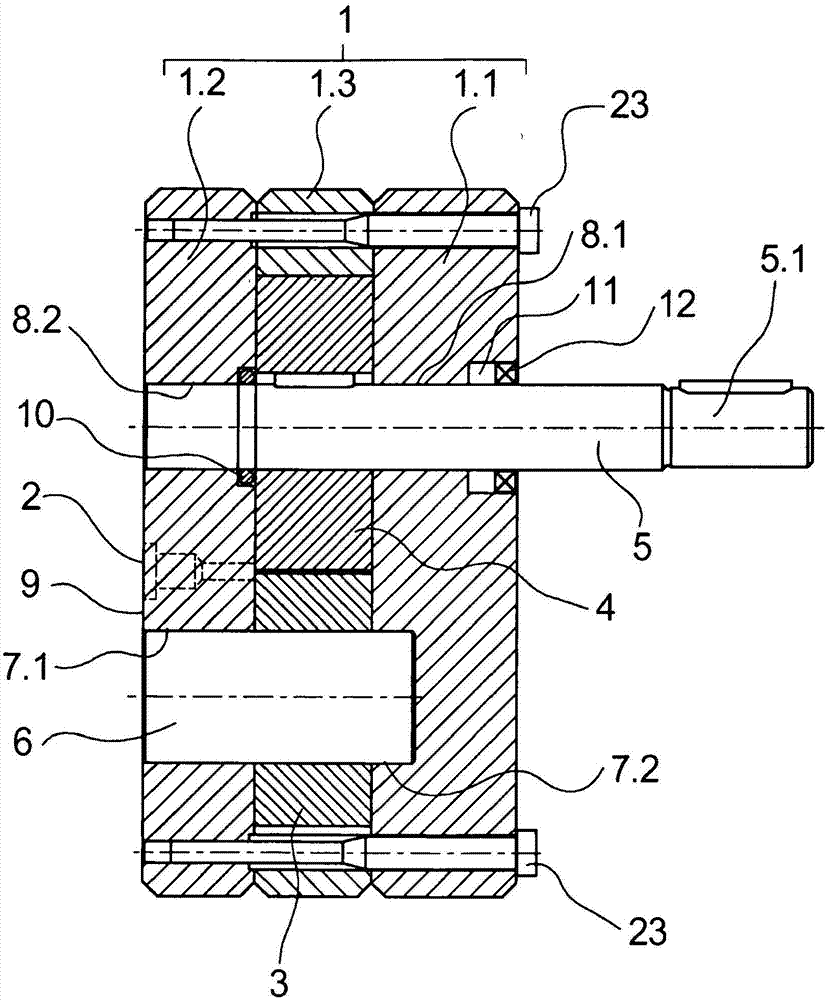

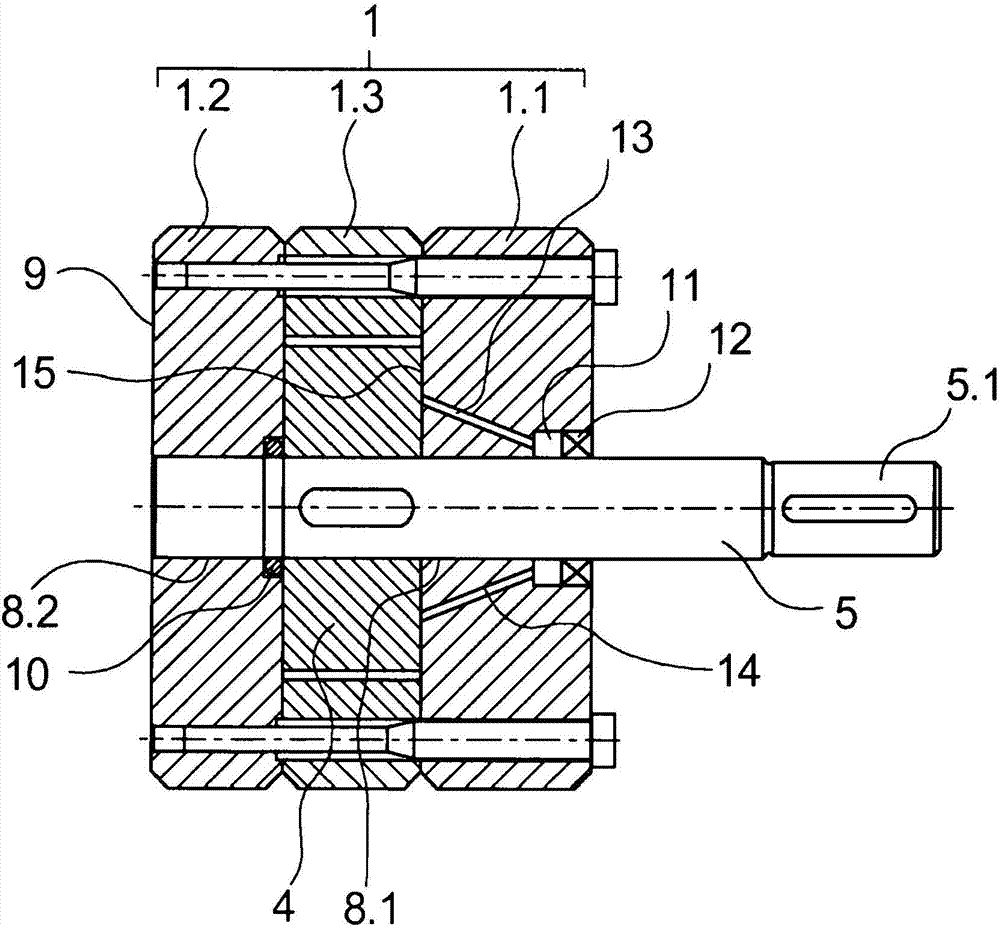

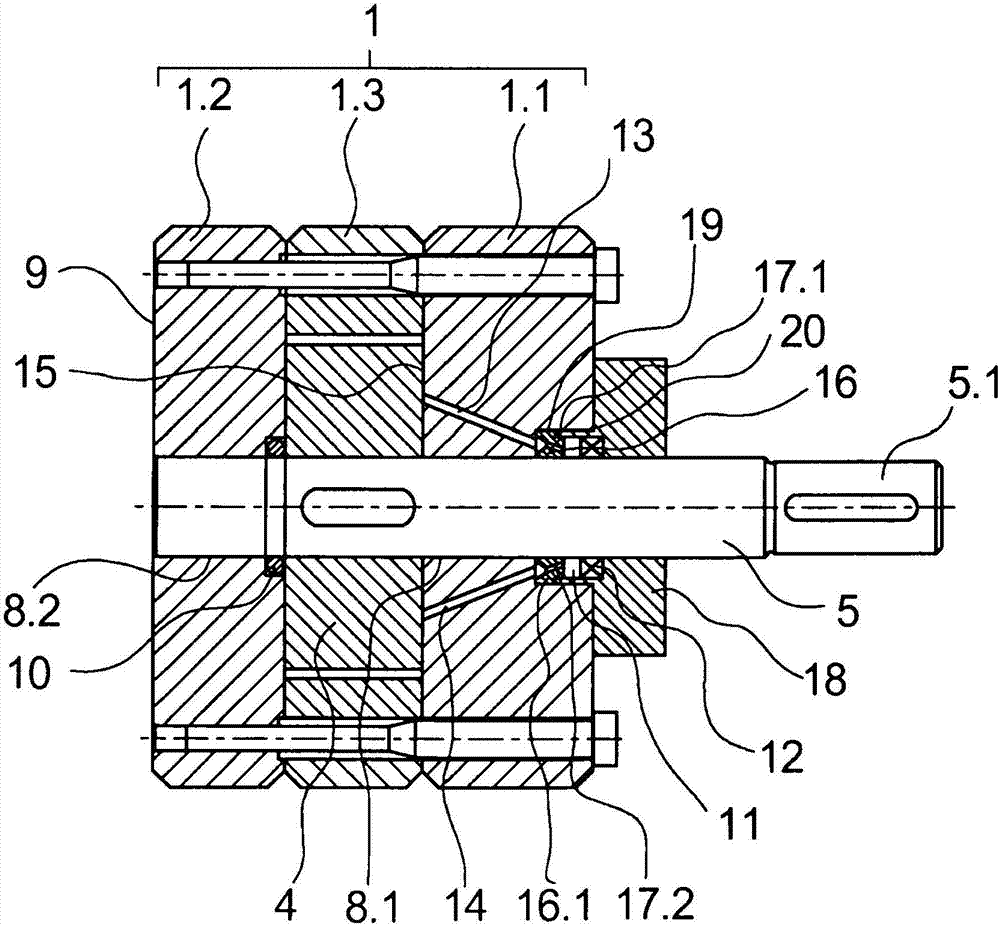

[0023] exist figure 1 with 2 A first embodiment of a gear pump according to the invention is shown in . here, figure 1 schematically shows a cross-sectional view of a gear pump and figure 2 A sectional view of the gear pump is shown in a section offset by 90° from the cross-sectional view.

[0024] The gear pump comprises a pump housing 1 . The pump housing 1 is constructed in multiple parts and has a plurality of housing plates 1 . The intermediate housing plate 1.3 has a recess for the two gear wheels 3 and 4 which mesh with each other. The middle housing plate 1.3 is held together with the gears 3 and 4 between the outer housing plates 1.1 and 1.2. One of the gears 3 is rotatably provided on the support pin 6 . For this purpose, the bearing pin 6 is held in a pin hole 7 . 1 in the outer housing plate 1 . 2 and in a pin hole 7 . 2 configured as a blind hole in the opposite outer housing plate 1 . 1 . The second gearwheel 4 is arranged on the pump shaft 5 in a rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com