Coil fan generator blade and its adjustment method

A generator blade, coil type technology, applied in wind power generation, machines/engines, wind turbines, etc., to achieve the effect of expanding the range of wind speed use, reducing energy capture, and enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is further described and explained:

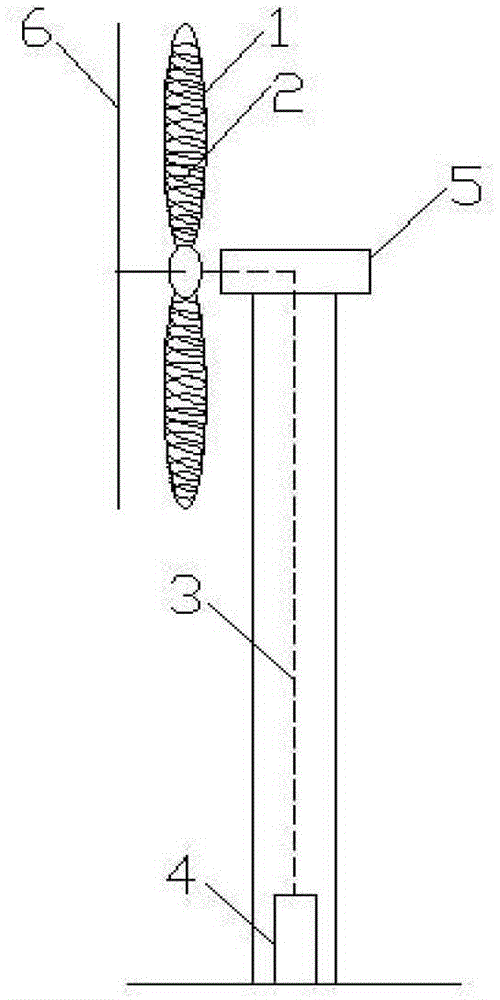

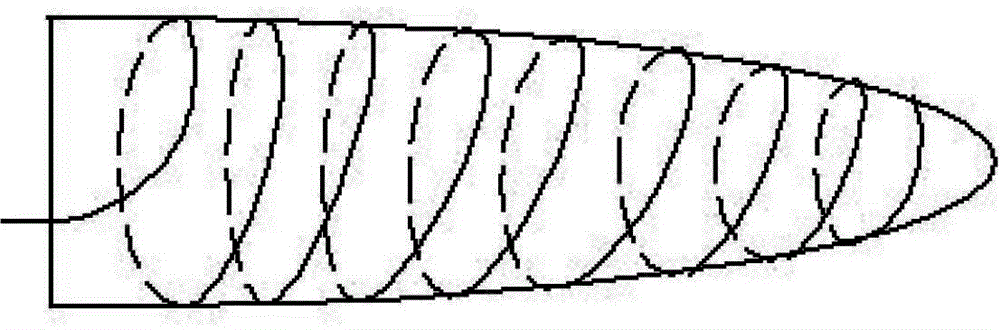

[0018] refer to figure 1 and figure 2 The coil 2 is added to the hollow part of the blade main body 1. The coil 2 is placed on both sides of the hollow web, symmetrically arranged, and directly in contact with the web. The circle formed by the coil has a smaller radius near the blade root Large, smaller near the blade tip, forming a shape that gradually decreases along the length of the blade. The coil pipe 2 is connected to the water tank 4 through the connecting pipe 3, and the water tank 4 is placed at the bottom inside the tower, and the connecting pipe is provided with a water pump and a valve, which are controlled by the drainage and injection control system. The water injection control system 5 is placed in the control box of the engine room, and is responsible for automatically adjusting the water in and out of the coil. The row water injection indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com