Drill power system

A power system and drilling rig technology, applied in rotary drilling rigs, electromechanical devices, mechanical equipment, etc., can solve the problems of complex diesel engine structure, backward technology, large environmental pollution, etc., achieve significant energy saving effect, avoid manual maintenance, and high transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

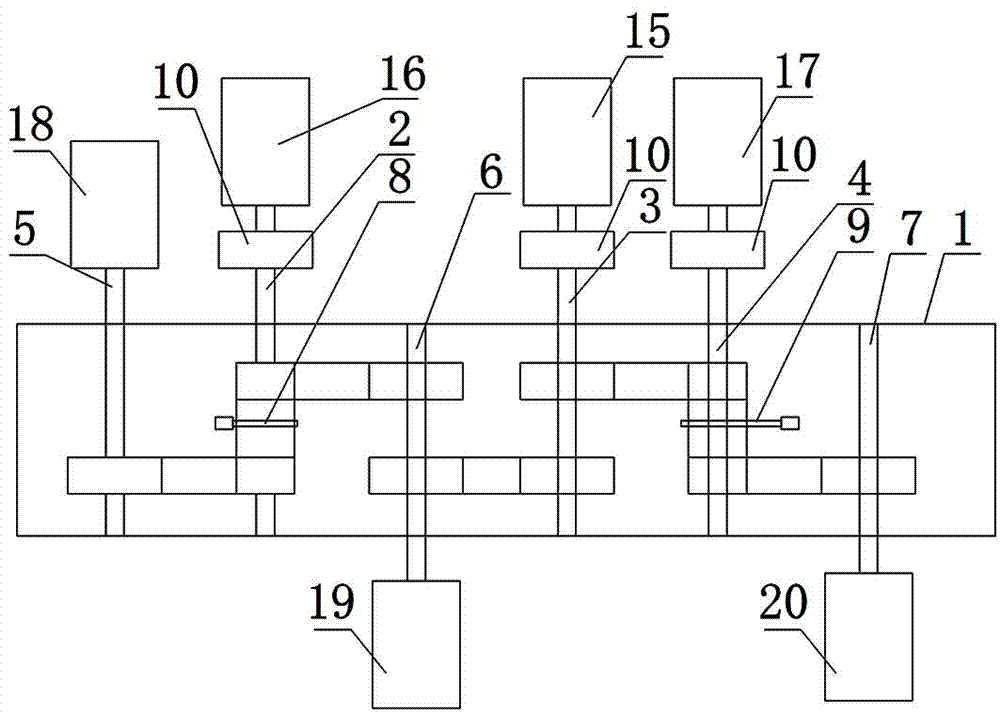

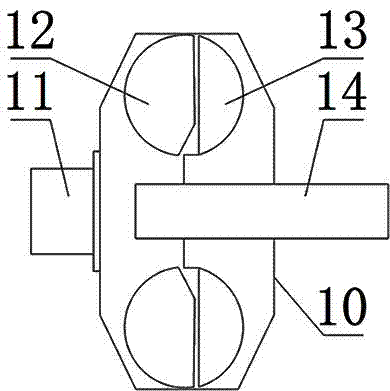

[0012] Such as figure 1 As shown, a drilling rig power system includes a diesel engine 15, an electric motor A16, an electric motor B17, a parallel box, a drawworks 18, a mud pump A19, and a mud pump B20. The input shaft A2, input shaft B3, input shaft C4, output shaft A5, output shaft B6 and output shaft C7 on the body 1, the input shaft A2 is respectively connected to the output shaft A5 and the output shaft B6 through the chain, and the input shaft B3 is respectively connected through the chain The output shaft B6 and the input shaft C4, the input shaft C4 is also connected to the output shaft C7 through a chain, the input shaft A2 is located between the sprockets respectively connected to the output shaft A5 and the output shaft B6, and there is a shift fork A8, and the input shaft C4 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com