Textile machine with a large number of work positions

A technology of textile machinery and workstations, applied in the direction of continuous winding spinning machine, spinning machine, textile and papermaking, etc., can solve the problems of high cost and complicated manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

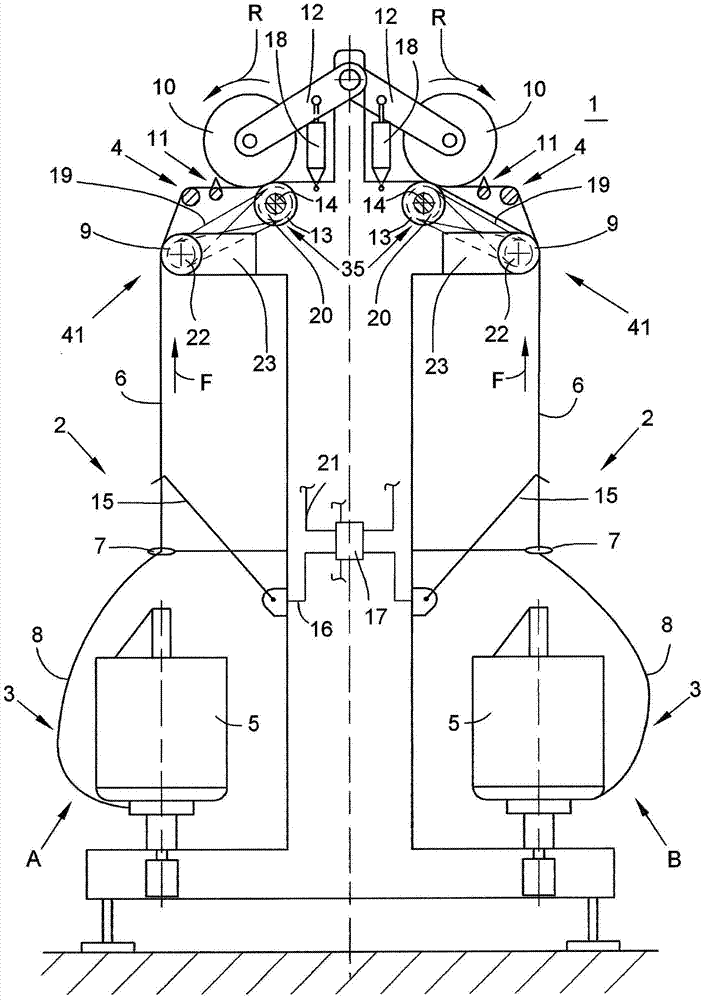

[0043] figure 1 A multi-station textile machine is shown schematically in a side view, in this example a double twister or a flyer type multi-strand rope twister 1 . As is known, such a textile machine has several stations 2 arranged side by side on both sides of the longitudinal axis of the machine. The station 2 of such a double twister or flyer 1 is especially equipped with a double twist device 3 and a winding device 4 . exist figure 1 In the embodiment shown, the yarn 6 drawn off by the double twist spindle 5 is passed to the winding device 4 via a yarn guide 7 which, during the twisting operation, delimits the yarn present in the region of the twisting device 3 . The height of the balloon 8 at which the yarn 6 is wound into a cross-wound bobbin 10 .

[0044] As is customary, the winding device 4 has a creel 12 for rotatably holding the cross-wound bobbins 10 , wherein the creel 12 can be lifted as required by means of a cylinder 18 . Furthermore, the winding device 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com