Suspension polymerization method for reducing polyvinyl chloride resin fisheyes

A polyvinyl chloride resin, suspension polymerization technology, applied in the field of polymer polymerization, can solve the problem of few fish eyes, etc., achieve the effect of improving aging whiteness, strong operability, and reducing the number of fish eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

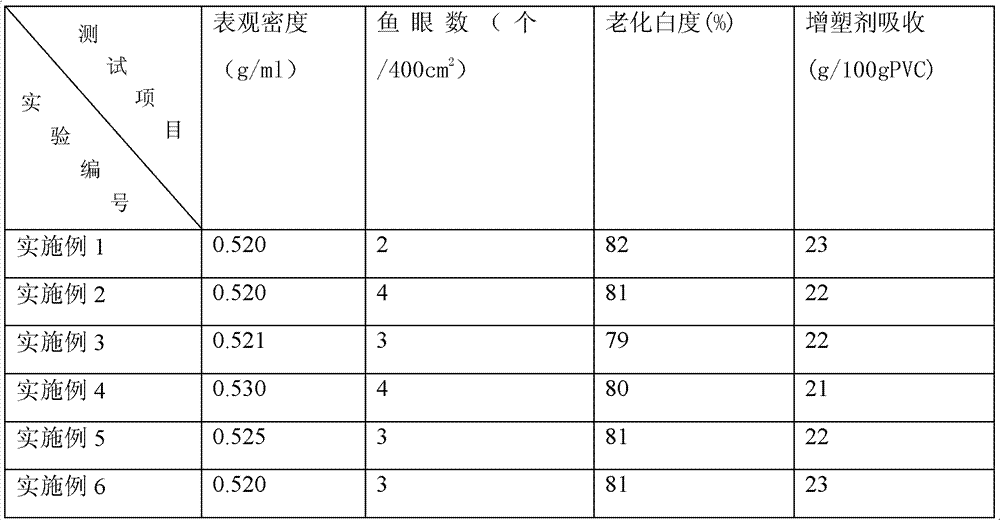

Examples

Embodiment 10

[0041] Example 10 and Example 11 are for investigating the effect of stabilizers on aging whiteness. No anti-fish-eye agent is added. When the anti-fish-eye agent is used, the anti-fish-eye agent is formulated into an ethanol solution with a mass concentration of 10%.

Embodiment 1

[0043] Rinse the polymerizer, apply anti-sticking agent and rinse, then vacuum, and suck in 140 parts of deionized water and composite dispersant (polyvinyl alcohol: hydroxypropyl methyl cellulose = 10: 1) 0.15 parts, composite initiator (cumyl peroxyneoheptanoate: dicyclohexyl peroxydicarbonate = 1:3) 0.10 parts, anti-fisheye agent (tert-butyl hydroquinone) 0.001 parts , 0.1 part of stabilizer (octadecyl alcohol), then vacuum to -0.098MPa, add 100 parts of vinyl chloride monomer of formula, cold stir for 10 minutes, heat up to reaction temperature 58.5℃ and start timing, polymerization pressure is 0.90MPa, When the polymerization temperature is maintained until the polymerization pressure drops by 0.10 MPa, 0.02 part of diethylhydroxylamine is added to terminate the reaction, the monomer is recovered and the material is discharged, and the PVC resin is obtained after centrifugal drying. The test results obtained in this example are shown in Table 1.

Embodiment 2

[0045] Rinse the polymerizer, apply anti-sticking agent and rinse, then vacuum, and suck in 140 parts of deionized water and composite dispersant (polyvinyl alcohol: hydroxypropyl methyl cellulose = 10: 1) 0.15 parts, composite initiator (cumyl peroxyneoheptanoate: dicyclohexyl peroxydicarbonate = 1:1) 0.10 parts, anti-fish eye agent (tert-butyl-4-hydroxyanisole) ) 0.001 part, 0.1 part of stabilizer (octadecyl alcohol), then vacuumize to -0.098MPa, add 100 parts of formula amount of vinyl chloride monomer, cold stir for 10 minutes, heat up to reaction temperature of 58.5℃ and start timing, polymerization pressure is 0.90MPa, when the polymerization temperature is maintained until the polymerization pressure drops by 0.10MPa, 0.02 part of diethylhydroxylamine is added to terminate the reaction, the monomer is recovered and the material is discharged, and the PVC resin is obtained after centrifugal drying. The test results obtained in this example are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com