Load-type metallocene catalyst, preparation method thereof and application thereof

A metallocene catalyst and a metallocene compound technology are applied to the supported metallocene catalyst and the fields of preparation and application thereof, and can solve the problems of low catalytic activity, low polymerization temperature, easy sticking of polymers, energy consumption and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a method for preparing the above-mentioned supported metallocene catalyst, the preparation method comprising: under the protection of an inert gas, ball milling anhydrous magnesium chloride and alkylaluminoxane at a temperature of 15-100°C for 0.1- 100 hours, then under the protection of an inert gas, the carrier is first contacted with the first solution to obtain the carrier after the first contact, and the first solution contains the product obtained by ball milling and the first solvent; remove the first contact after the first solution The first solvent on the carrier; the second contact is carried out between the carrier removed from the first solvent and the second solution to obtain the second contacted carrier, the second solution contains the metallocene compound and the second solvent, wherein, The carrier is hollow spherical mesoporous silica, the average particle diameter of the carrier is 3-20 microns, the specific surfac...

Embodiment 1

[0092] This example is used to illustrate the supported metallocene catalyst and its preparation method according to the present invention.

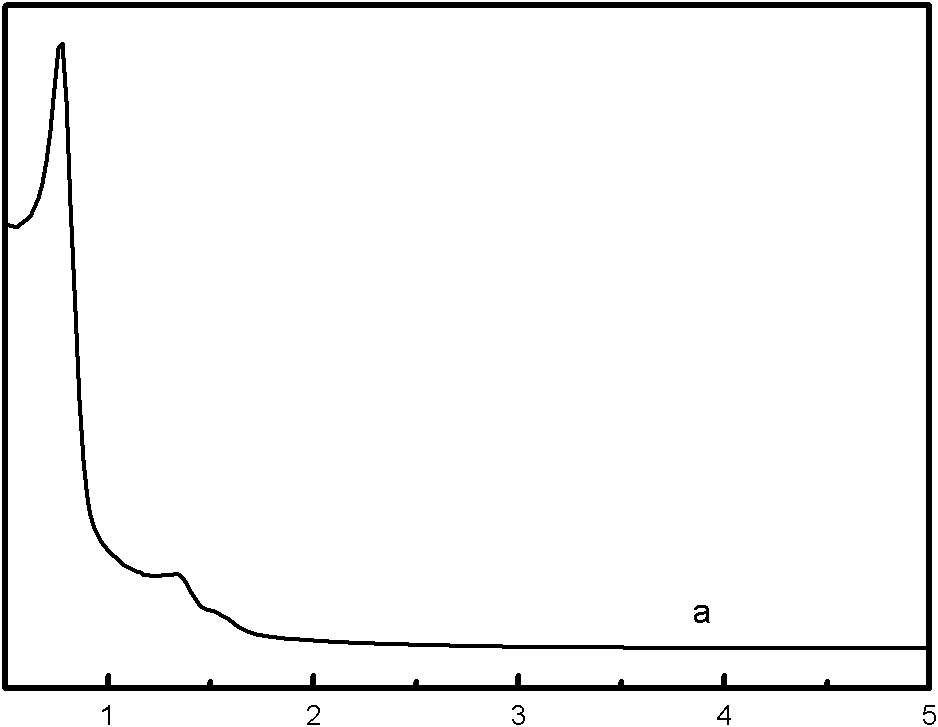

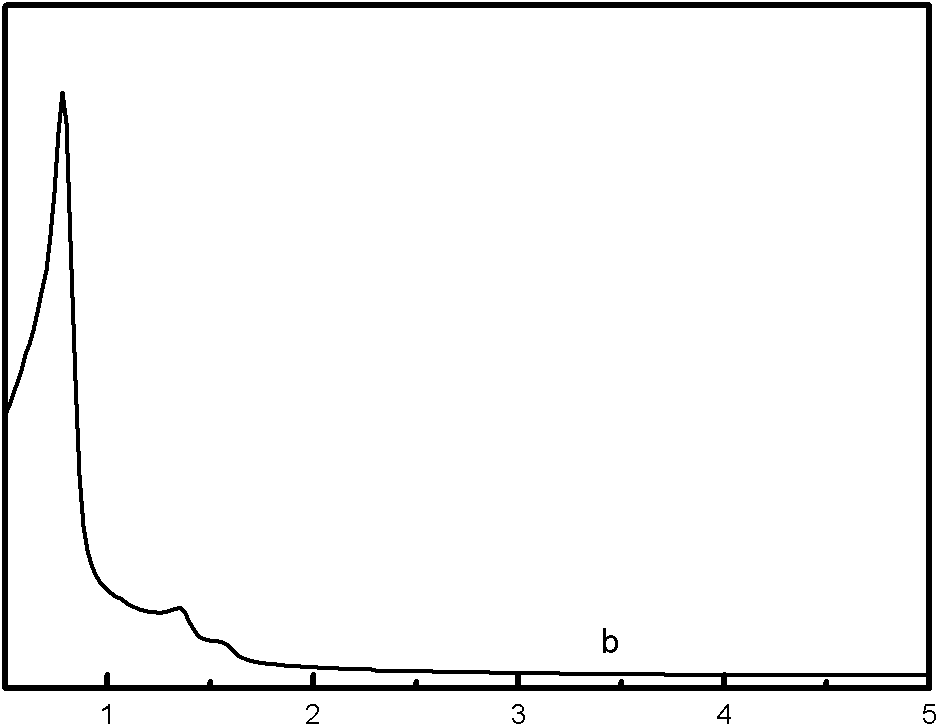

[0093] Add 1.0 gram of triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene (Aldrich Company, P123) and 1.69 gram of ethanol into the buffer solution (pH=4.4) of acetic acid and sodium acetate of 28ml, at 15 ℃ Stir until the polyoxyethylene-polyoxypropylene-polyoxyethylene is completely dissolved, then add 6g of trimethylpentane to the above solution, stir at 15°C for 8 hours, then add 2.13 grams of tetramethoxysilane to the In the above solution, after stirring for 20 hours at 15°C, the solution was transferred to a polytetrafluoroethylene-lined reactor, and crystallized in an oven at 60°C for 24 hours, then filtered, washed with distilled water, and dried to obtain mesoporous hollow spheres. Silicon oxide raw powder.

[0094] The hollow spherical mesoporous silica raw powder obtained in the previous step was calcined in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com