High wear-proof and cracking resistant color surface decorative building material

A color surface, high wear-resistant technology, applied in the direction of architecture, building structure, covering/lining, etc., can solve the problems of poor wear resistance, easy cracking, etc., and achieve the effect of clear texture, not easy to change color, and realistic color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

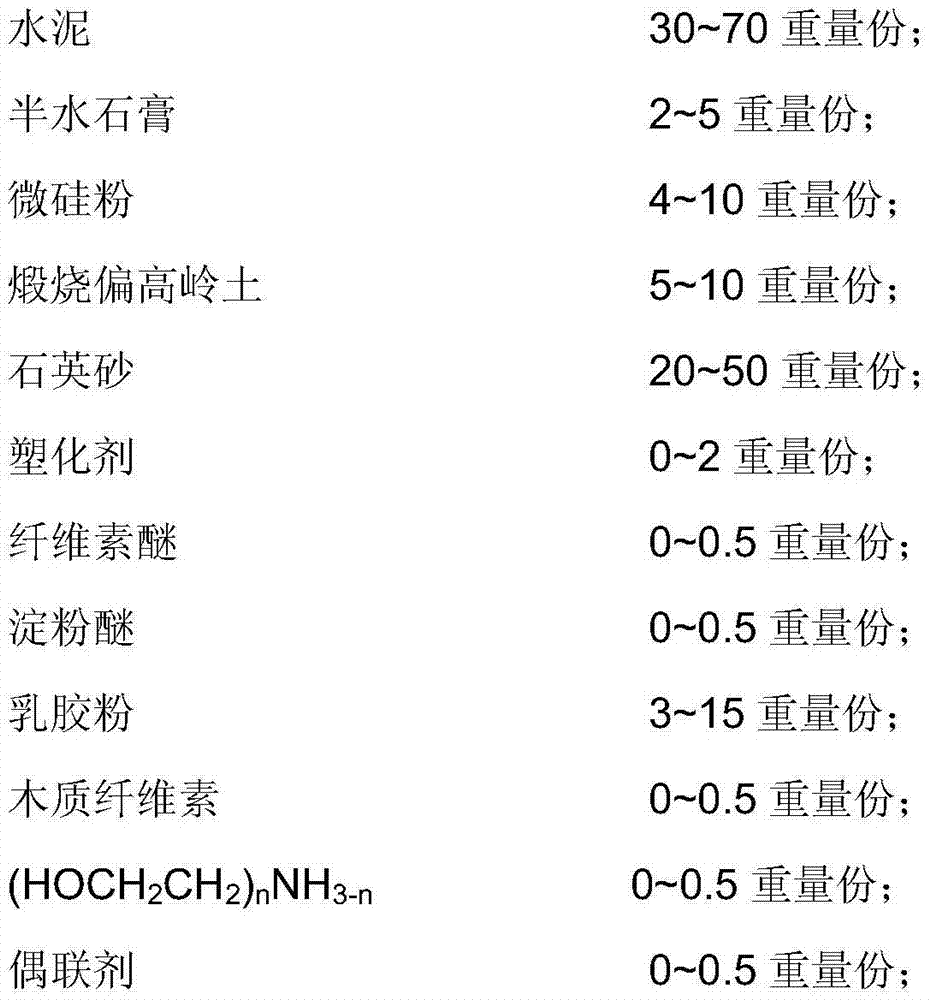

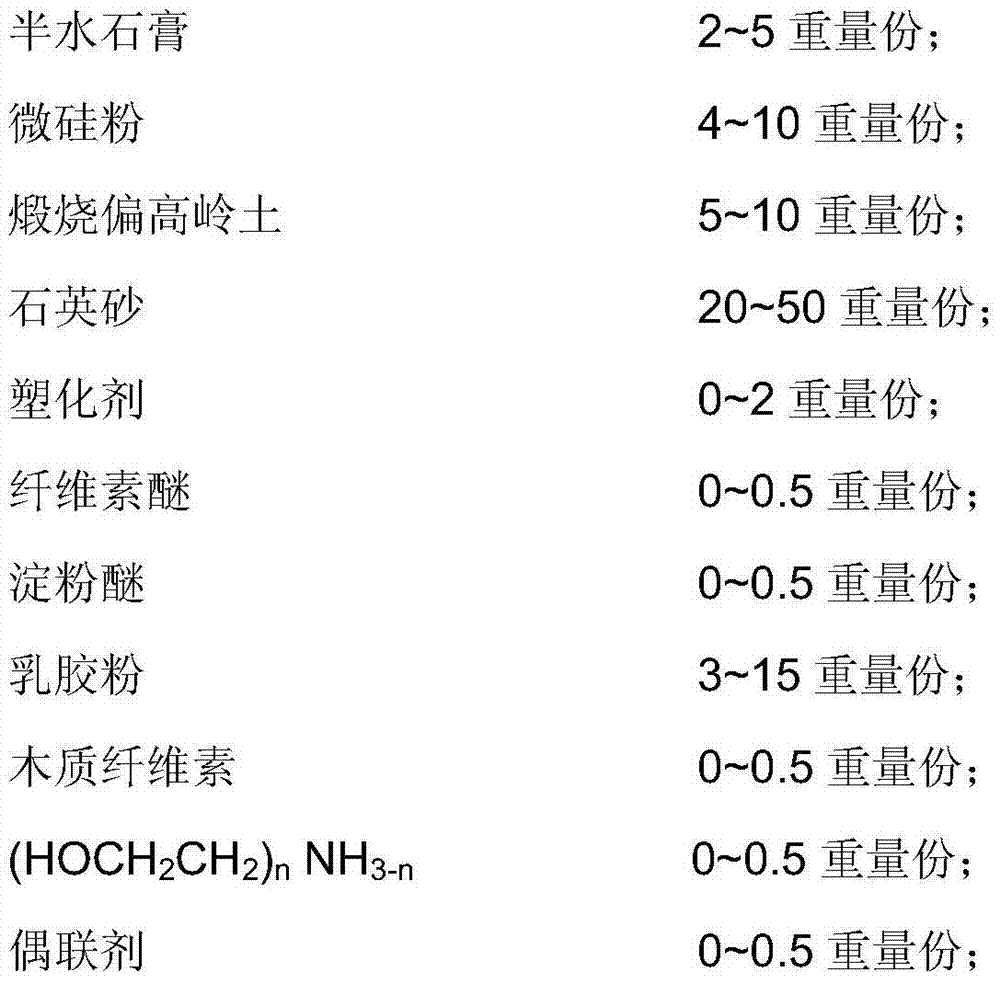

[0061] Step 1. Use natural or pre-processed decorative building material models to remake molds according to the needs of the market and customers. Prepare structural slurry, surface color slurry and wear-resistant and anti-cracking slurry. Among them, the components of the wear-resistant and anti-cracking slurry include:

[0062] 35 parts by weight of white Portland cement;

[0063] 3.5 parts by weight of white aluminate cement

[0064] 2 parts by weight of hemihydrate gypsum;

[0065] Microsilica fume 4 parts by weight;

[0066] 5 parts by weight of calcined metakaolin;

[0067] 20 parts by weight of quartz sand;

[0068] 0.4 parts by weight of high-performance polycarboxylate superplasticizer;

[0069] 0.02 parts by weight of cellulose ether;

[0070] 0.01 parts by weight of starch ether;

[0071] 3 parts by weight of acrylic acid redispersible latex powder;

[0072] 0.1 parts by weight of lignocellulose;

[0073] Diethanolamine 0.01 part by weight;

[0074] 0.05 ...

Embodiment 2

[0080] Step 1. Use natural or pre-processed decorative building material models to remake molds according to the needs of the market and customers. Prepare structural slurry, surface color slurry and wear-resistant and anti-cracking slurry. Among them, the components of the wear-resistant and anti-cracking slurry include:

[0081] 35 parts by weight of white Portland cement;

[0082] 3.5 parts by weight of white aluminate cement

[0083] 2 parts by weight of hemihydrate gypsum;

[0084] Microsilica fume 4 parts by weight;

[0085] 5 parts by weight of calcined metakaolin;

[0086] 20 parts by weight of quartz sand;

[0087] 0.4 parts by weight of high-performance polycarboxylate superplasticizer;

[0088] 0.02 parts by weight of cellulose ether;

[0089] 0.01 parts by weight of starch ether;

[0090] 0.02 parts by weight of polyacrylic acid rheological agent;

[0091] 3 parts by weight of acrylic acid redispersible latex powder;

[0092] 0.1 parts by weight of lignoce...

Embodiment 3

[0101] Step 1. Use natural or pre-processed decorative building material models to remake molds according to the needs of the market and customers. Prepare structural slurry, surface color slurry and wear-resistant and anti-cracking slurry. Among them, the components of the wear-resistant and anti-cracking slurry include:

[0102] 40 parts by weight of white Portland cement;

[0103] 4 parts by weight of white aluminate cement

[0104] 2 parts by weight of hemihydrate gypsum;

[0105] Microsilica fume 5 parts by weight;

[0106] 6 parts by weight of calcined metakaolin;

[0107] 39 parts by weight of quartz sand;

[0108] 0.6 parts by weight of high-performance polycarboxylate superplasticizer;

[0109] 0.02 parts by weight of cellulose ether;

[0110] 0.01 parts by weight of starch ether;

[0111] Polyacrylic acid rheological agent 0.02 parts by weight

[0112] Silicone acrylic redispersible latex powder 3 parts by weight;

[0113] 0.3 parts by weight of lignocellulo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com