Backpack type sprayer

A sprayer and knapsack technology, applied in the field of knapsack sprayers, can solve the problems of easy clogging of nozzles, low efficiency, waste of labor, etc., and achieve the effects of preventing impurities from clogging the spray gun, reducing labor, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

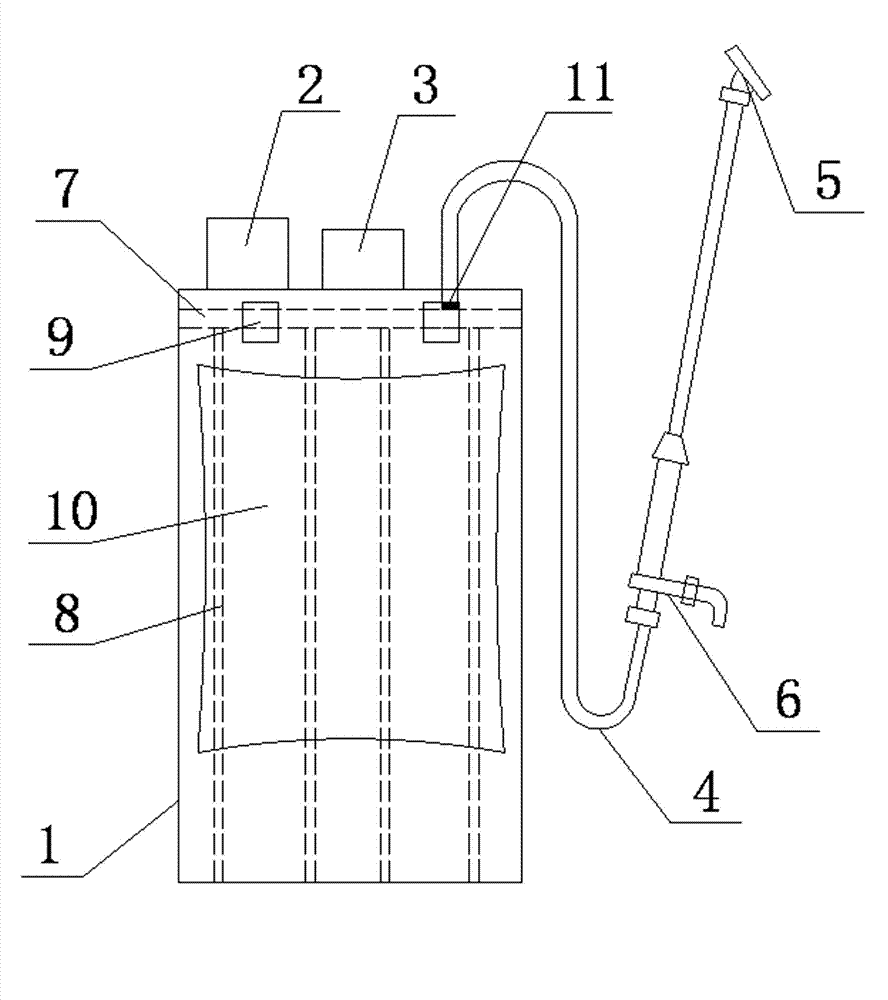

[0013] Such as figure 1 As shown, a knapsack sprayer of the present invention includes a liquid storage tank 1, the top of the liquid storage tank 1 is provided with a sealable liquid filling port 2 and a pressurizing device 3, and the top of the liquid storage tank 1 is also provided with Spray gun 4, described spray gun 4 is connected with shower head 5, also is provided with control valve 6 between described spray gun 4 and shower head 5, and described spray gun 4 is positioned at liquid storage tank 1 inside and is connected with connection pipe 7, and described connection pipe 7 is positioned at The top of the liquid storage tank 1 is fixed on the inner wall of the liquid storage tank 1, the connecting pipe 7 is connected to one end of a plurality of infusion tubes 8, and the other end of the infusion tube 8 is located at the bottom of the liquid storage tank 1, which can quickly and effectively make the liquid enter the spray gun , to reduce labor force, the top of one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com