Method and plant for printing hides

A technology of leather and equipment, applied in the field of letterpress printing of industrial leather, can solve problems such as loss of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

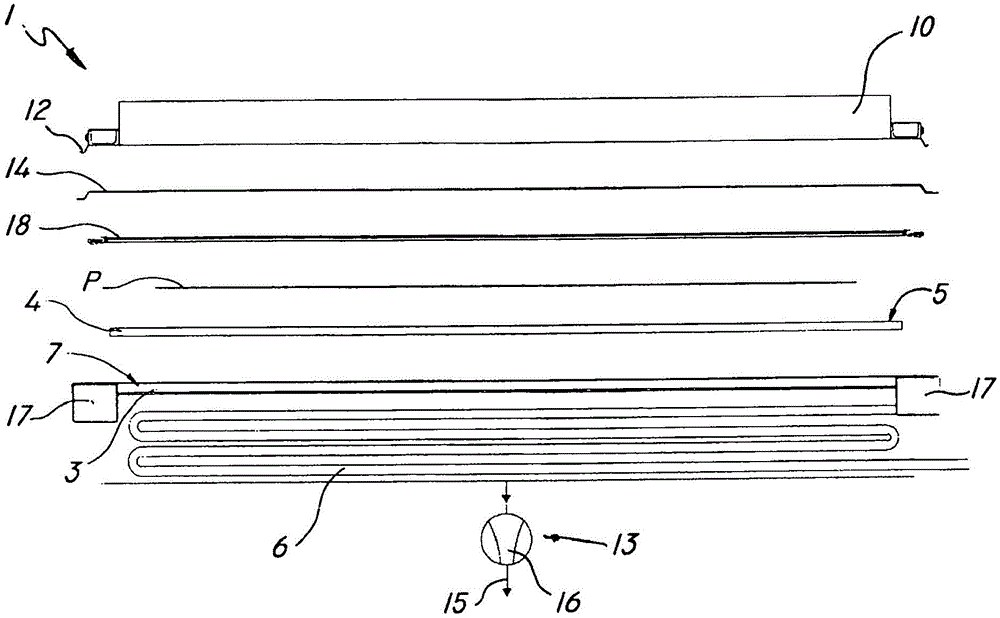

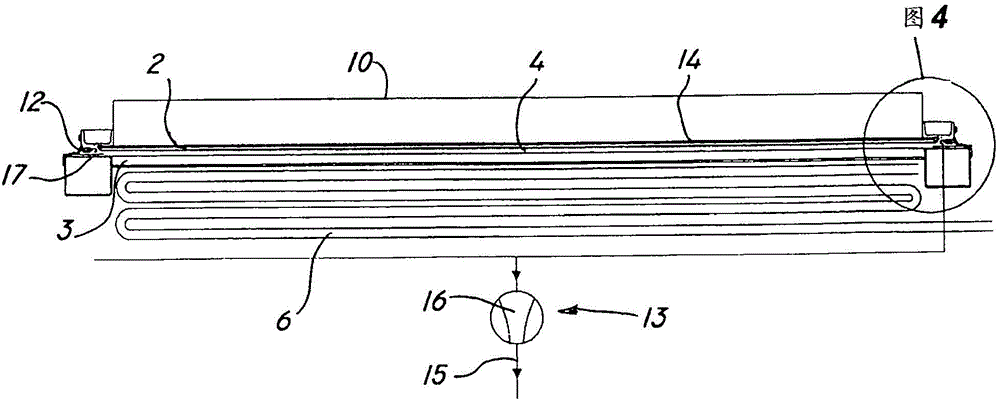

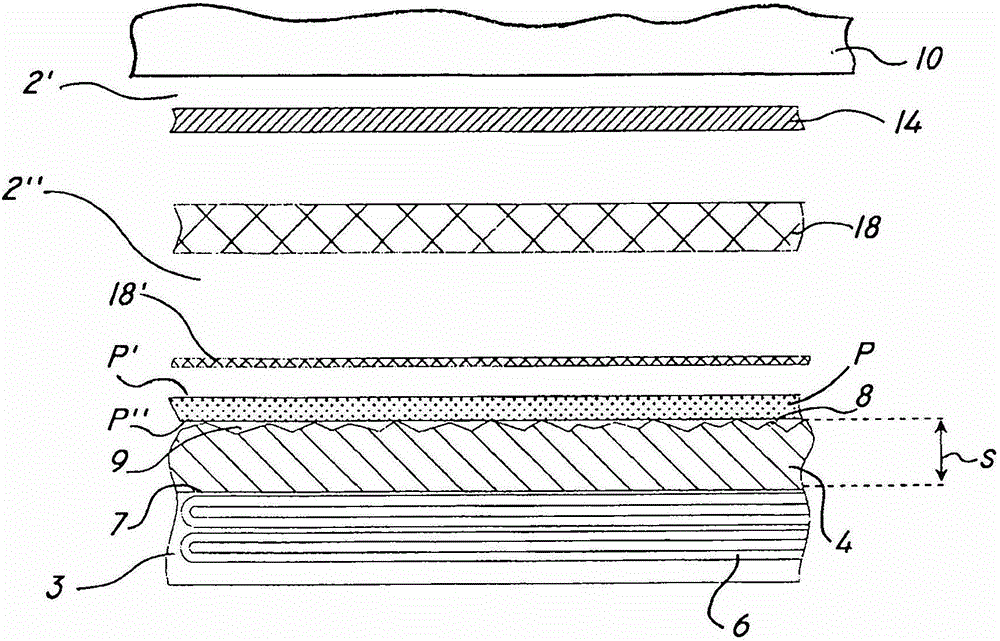

[0033] With reference to the above-mentioned figures, an apparatus for printing industrial leather according to the invention, indicated generally at 1, can be incorporated in a leather processing line, the drying station forming part of this apparatus.

[0034] According to the invention, the apparatus 1 comprises a hermetically sealed drying chamber 2 containing inside a support surface 3 for one or more hides P to be treated and one or more Template 4.

[0035] Each stencil 4 has an upper surface 5 which inversely reproduces the pattern to be printed on the leather P. As shown in FIG.

[0036] In particular, stencils 4 that are longitudinally offset from each other may have respective upper surfaces 5 that are shaped differently relative to each other so that on a corresponding leather P or on the same leather P extending over two or more stencils 4 Print the corresponding decorative pattern.

[0037] Associated with the support surface 3 are heating means 6 suitable for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com