Automatic assembly device of breaker terminal screw

An automatic assembly device and terminal technology, which is applied in emergency protection devices, emergency protection device manufacturing, circuits, etc., can solve the problems of workers who are prone to fatigue and errors after repeated labor for a long time, the quality of assembly cannot be guaranteed, and the efficiency is low. Simple structure, lower labor costs, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

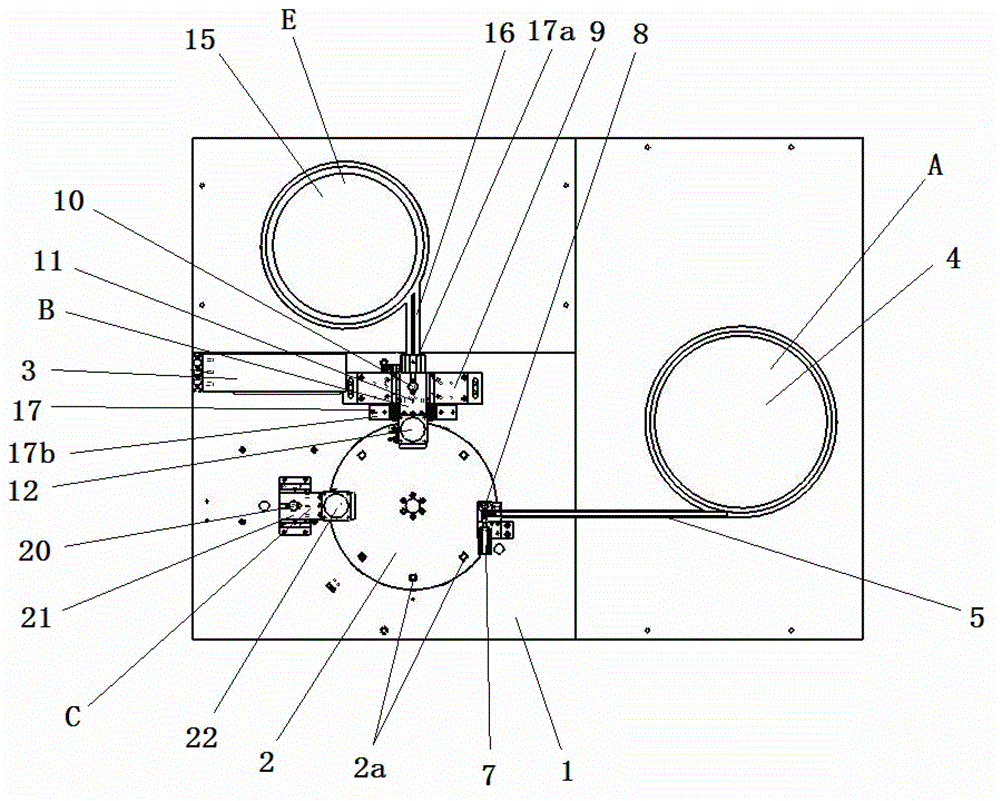

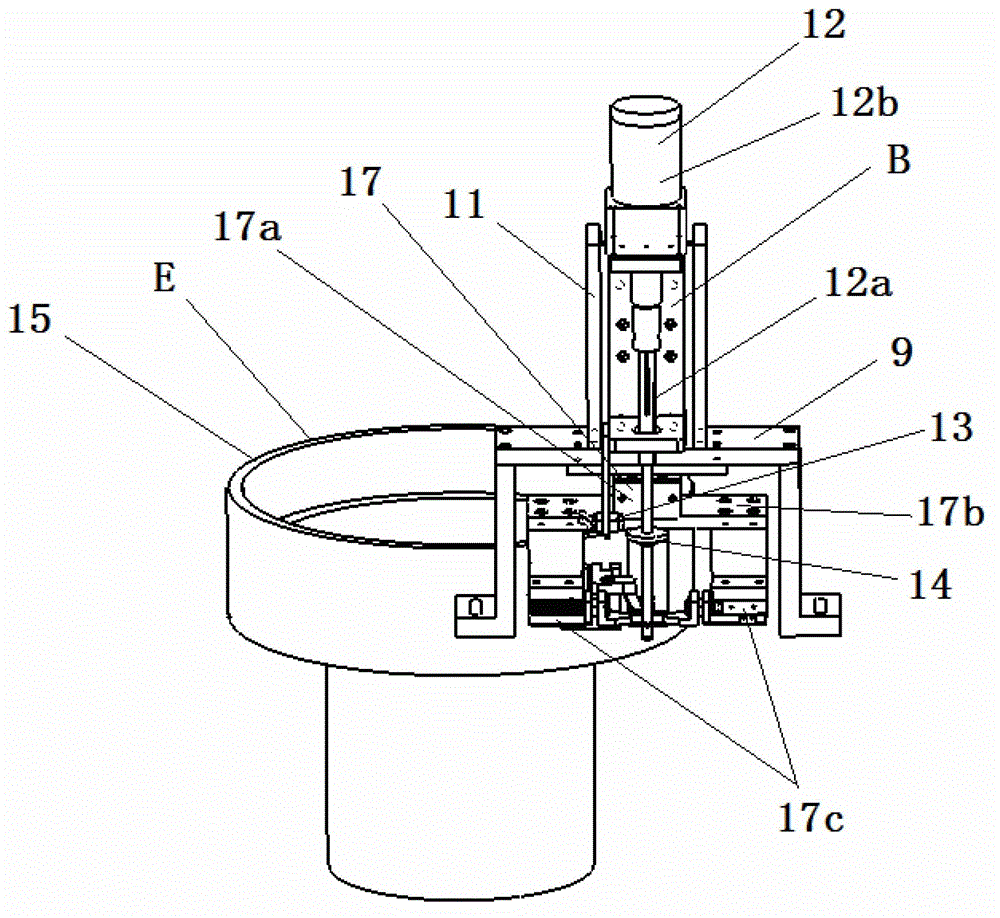

[0034] Example: Combine Figure 1~Figure 5 Shown is a specific implementation of the automatic assembly device for circuit breaker terminal screws provided by the present invention, which has a workbench 1, and the workbench 1 is provided with a turntable 2 and a PLC controller 3. In this embodiment The bottom of the turntable 2 is fixed to the output shaft of the cam splitter (not visible in the figure), while the input shaft of the cam splitter is connected to the drive motor through the reducer, and the drive motor is connected to the PLC controller 3 . Specific as figure 1 As shown, in this embodiment, four stations are evenly spaced around the turntable, and terminal post feeding devices A, A, Screw matching detection device B, screw removal device C and qualified product unloading device D (see Figure 5 ). The turntable 2 in this embodiment is provided with 8 terminal positioning holes 2a that are equiangularly and evenly spaced relative to the center of the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com