Special three-phase three-pole amorphous alloy transformer for solar power generation

An amorphous alloy, three-phase three-column technology, applied in transformers, fixed transformers, transformer/inductor cores, etc., to achieve the effects of reducing power generation loss, ultra-low no-load loss, and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

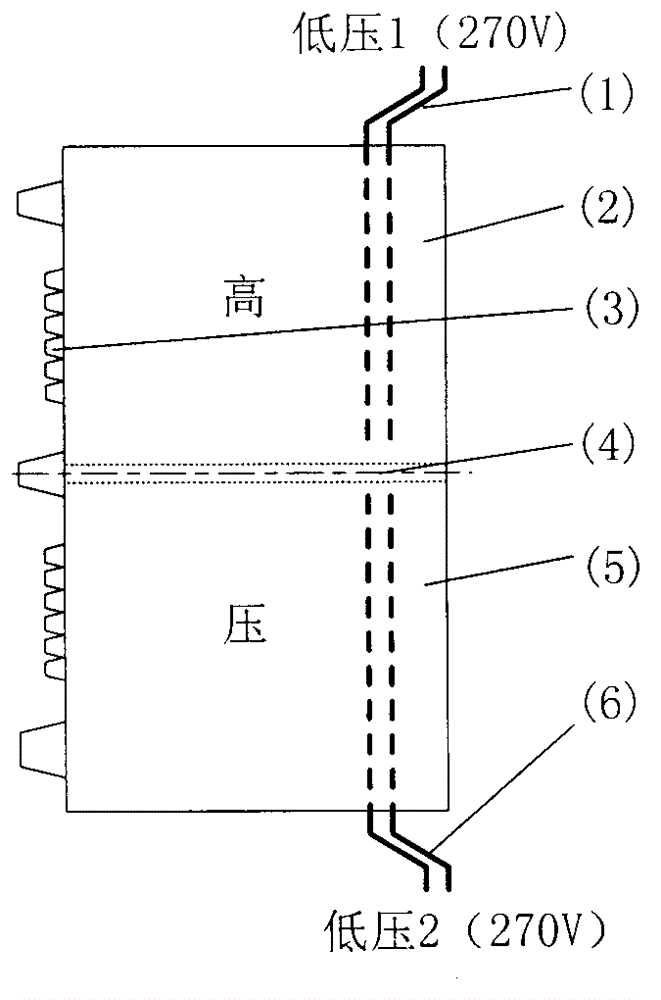

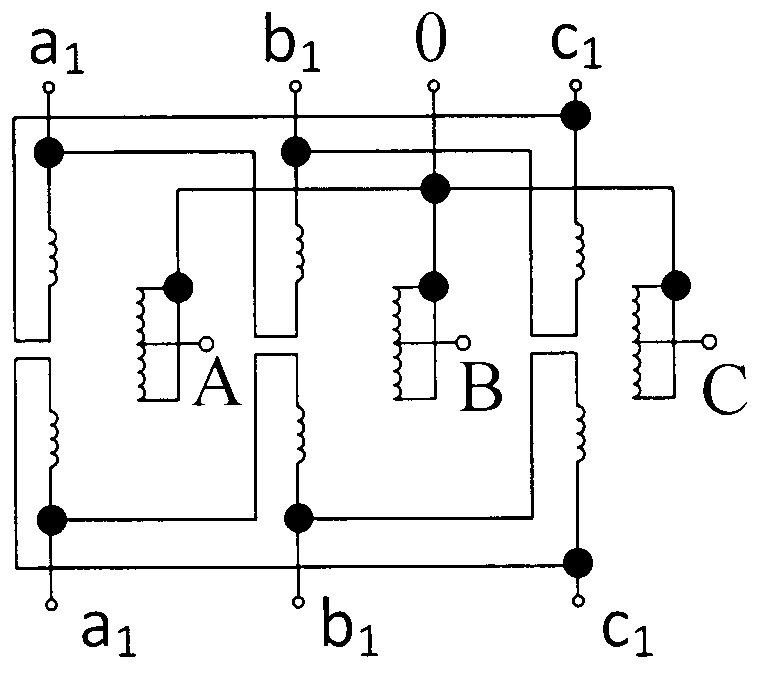

[0012] The present invention is further described below: the transformer uses amorphous alloy as the core to make an amorphous alloy iron core distribution transformer, which can reduce the no-load loss of the transformer to about 25% of SCB11 type, and its efficiency can reach more than 98%. The iron core adopts a three-phase three-column structure, which can not only be used for connection group Dyn11, but also meet the wiring requirements of Yyn0, and has a wide range of applications. The internal winding adopts a three-phase split winding structure, with one high-voltage winding and two low-voltage windings, and the sum of their capacities is equal to the total capacity of the transformer. After the low-voltage winding is split, the distance between the high-voltage coil and each low-voltage coil will be greatly increased, as well as the short-circuit impedance value between the parts after the low-voltage coil is split. This will limit the short-circuit current of the netw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com