Water pressure test sealing device of anti-explosion motor base

A hydraulic test and sealing device technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as consumption of connection process bolts, troublesome assembly and disassembly, and bolt breakage, so as to prevent bolt breakage, save process bolts, reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

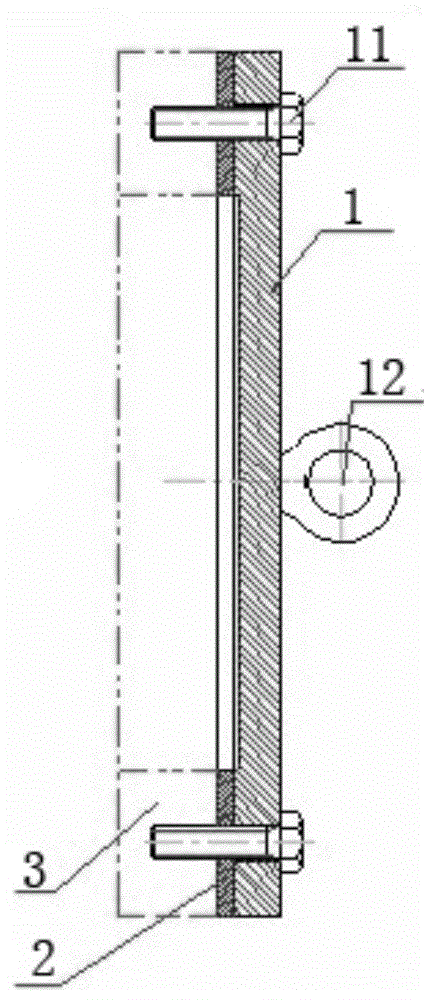

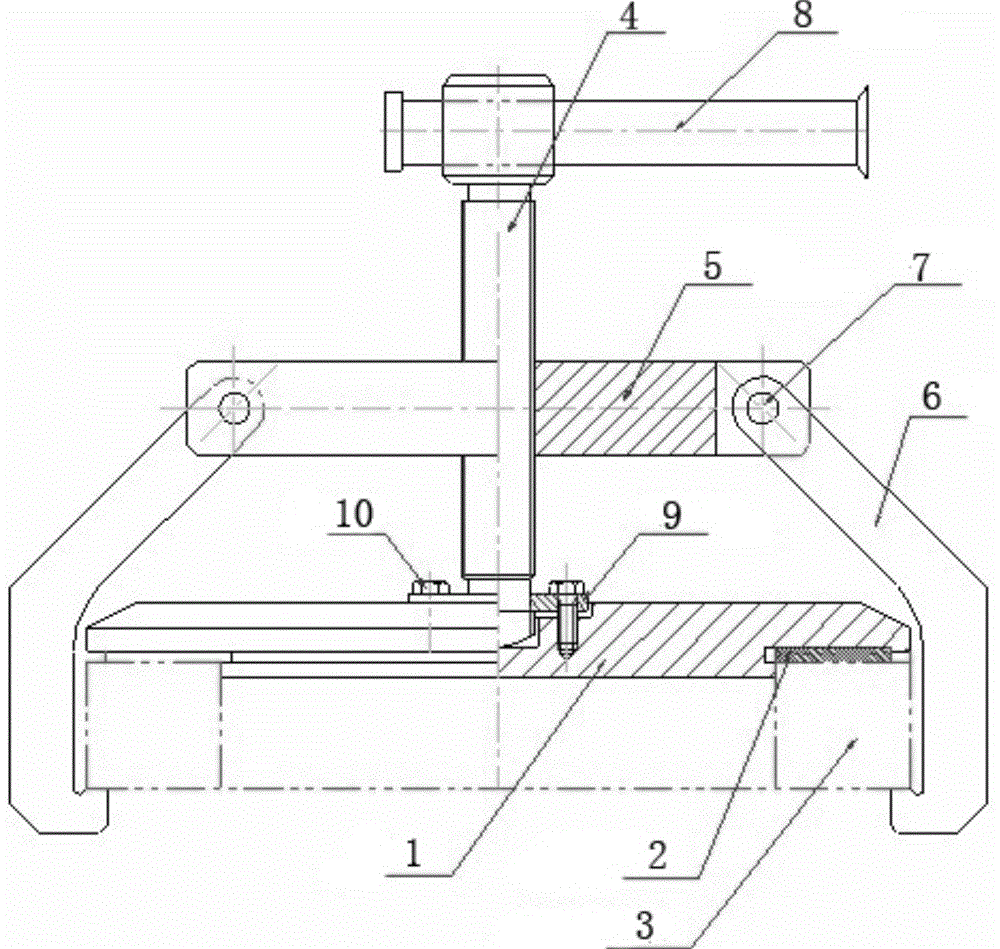

[0013] Embodiment 1: see image 3 , the junction box pressure plate 1 and the machine base junction box seat plate 3 are installed together, and the compression sealing ring 2 is used for sealing. The sealing device of the explosion-proof motor frame hydraulic test adopts a compression screw vertically facing the center of the junction box pressure plate 4. A beam 5 is threaded on the compression screw 4, and J-shaped hooks 6 are movable and installed symmetrically at the end of the beam 5. The other end of each J-shaped hook 6 can be hung on the base plate 3 of the junction box. bottom edge to ensure uniform force. It can be seen from the figure that the hook is hinged at the end of the crossbeam by the pin shaft 7 . In addition, a helical handle 8 is installed laterally on the leaking end of the compression screw 4 .

[0014] The end of the compression screw 4 in contact with the junction box pressure plate 1 is provided with a screw pressure plate 9, the screw pressure p...

Embodiment 2

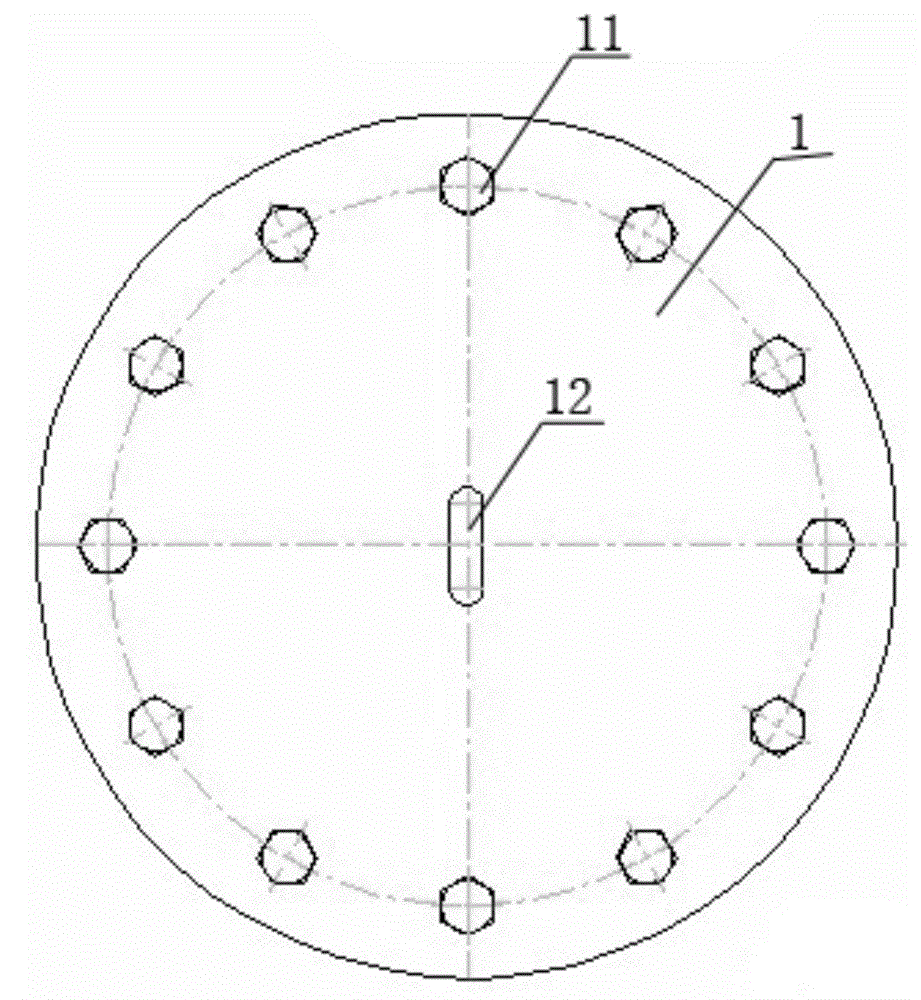

[0015] Example 2: see figure 1 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that there is another cooperative relationship between the compression screw 4 and the screw pressure plate 9: a concave hole is arranged in the center of the junction box pressure plate 1 groove, the center of the screw pressure plate 9 is provided with a through hole, the end of the compression screw 4 is arranged as a spherical surface and an annular groove is arranged near the spherical surface, and the annular groove is fixed in the center hole of the screw pressure plate 9 and can rotate relatively. The end spherical surface of the tightening screw 4 rotates and cooperates with the bottom of the groove at the center of the junction box pressing plate 3, and the screw pressing plate 9 at this moment plays a positioning role.

Embodiment 3

[0016] Embodiment 3: see figure 1 , the content is basically the same as that of Example 1, and the similarities will not be repeated. The difference is that the disc is used instead of the beam, the edge of the disc is evenly provided with notches, the J-shaped hook is matched and installed in the notch, and the J-shaped hook is matched with the notch. The inner side walls of the mouth are hinged together by a pin shaft 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com