Power head of vertical shaft type rock core drilling machine

A technology of core drilling rig and power head, applied in the field of power head, can solve the problems of six-dimensional equal division, flatness, smoothness, low quenching hardness, low manufacturing precision, etc., and is suitable for mass production , Avoid the effect of poor processing technology and fast complete set speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

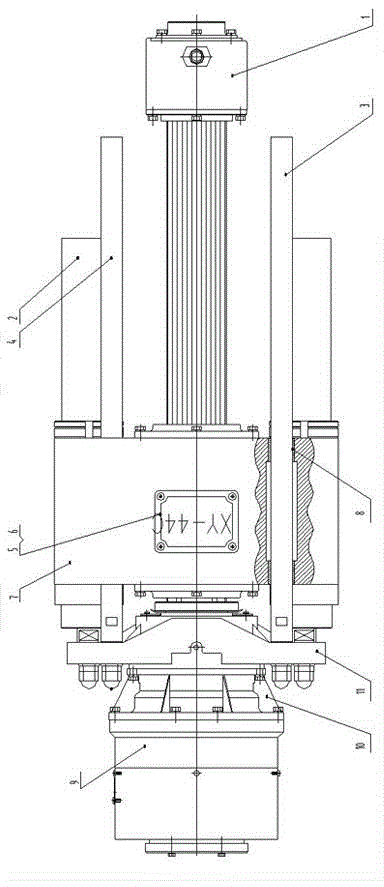

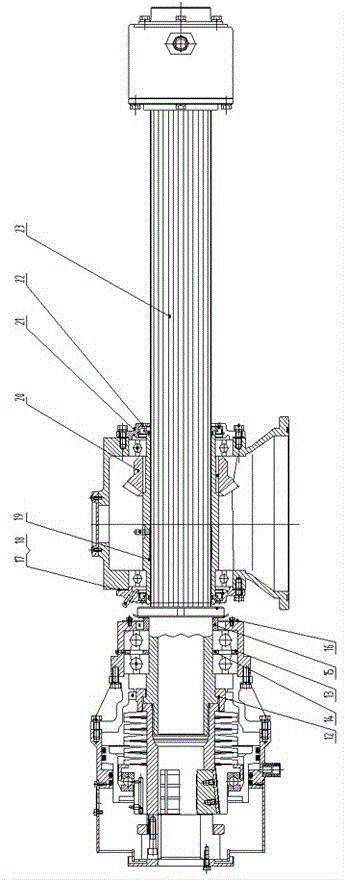

[0009] A power head of a vertical shaft core drilling rig, comprising a power head housing connected to a transfer case, pressure and decompression oil cylinders are arranged on the left and right sides of the power head housing, and a vertical shaft conduit is vertically arranged in the power head housing , the vertical shaft conduit is equipped with a vertical shaft, the upper end of the vertical shaft is connected with the hydraulic chuck, and a pressure beam is installed between the top of the vertical shaft and the hydraulic chuck, and the left and right ends of the pressure beam are connected downward with the pressure and pressure cylinder. The front part of the beam is provided with left and right guide rods downwards. The housing of the power head is provided with guide holes which cooperate with the left and right guide rods to play a guiding role. The middle transmission section of the vertical shaft is cylindrical, and the column in the middle transmission section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com