Dry sealing adhesive and preparation method thereof

A sealing glue and drying technology, applied in shellac adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve problems such as difficult to remove, human body, environmental pollution, poor oil resistance, etc., and reach the glue layer Easy to remove, less environmental pollution, good viscous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

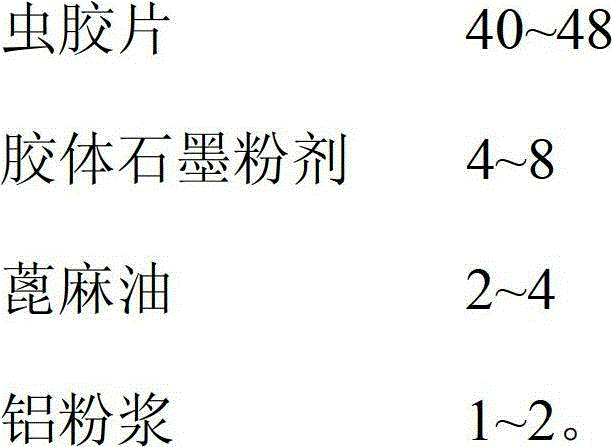

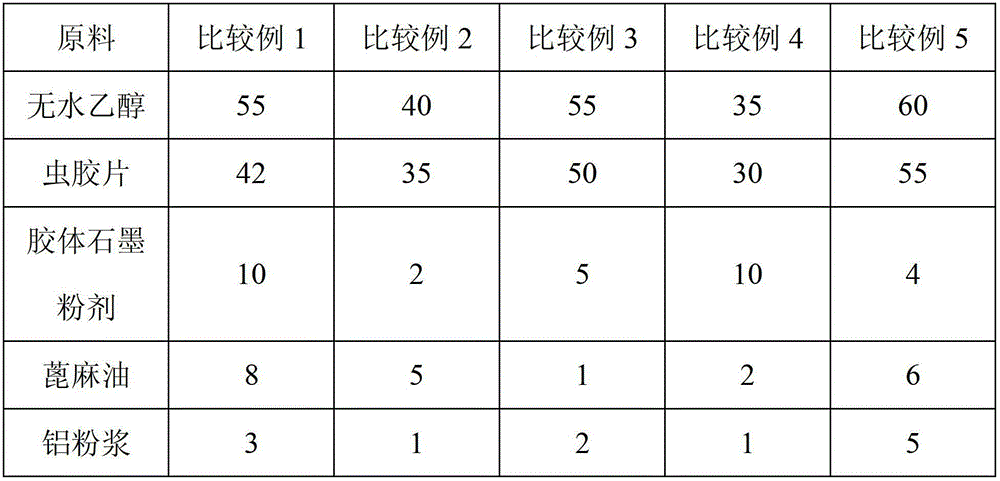

Method used

Image

Examples

Embodiment 1

[0018] First weigh 40g of shellac flakes with a balance, crush them and put them into a clean container, add 52g of absolute ethanol, cover the container tightly and leave it for 24 hours. After it is completely dissolved, add 2g of castor oil and stir evenly, then add 5g of colloidal graphite powder and stir Evenly, then add 1g of aluminum powder slurry and stir thoroughly (first dilute the aluminum powder slurry with a small amount of absolute ethanol) to form a uniform mixed glue.

Embodiment 2

[0020] First weigh 45g of shellac flakes with a balance, crush them and put them into a clean container, add 52g of absolute ethanol, cover the container tightly and leave it for 24 hours, after it is completely dissolved, add 3g of castor oil and stir evenly, then add 6g of colloidal graphite powder and stir Evenly, then add 1.5g of aluminum powder slurry and stir thoroughly (first dilute the aluminum powder slurry with a small amount of absolute ethanol) to form a uniform mixed glue.

Embodiment 3

[0022] First weigh 40g of shellac flakes with a balance, crush them and put them into a clean container, add 50g of absolute ethanol, cover the container tightly and leave it for 24 hours, after it is completely dissolved, add 3g of castor oil and stir evenly, then add 5g of colloidal graphite powder and stir Evenly, then add 2g of aluminum powder slurry and stir thoroughly (first dilute the aluminum powder slurry with a small amount of absolute ethanol) to form a uniform mixed glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com