Method for preparing ethanol via hydrogenation of acetic ester based on recirculating of recovered hydrogen

A technology of acetate and ethanol, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve problems such as large heat consumption, hydrogen waste, economic loss, etc., to reduce heating and cooling energy consumption, reduce Cost, effect of high acetate conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

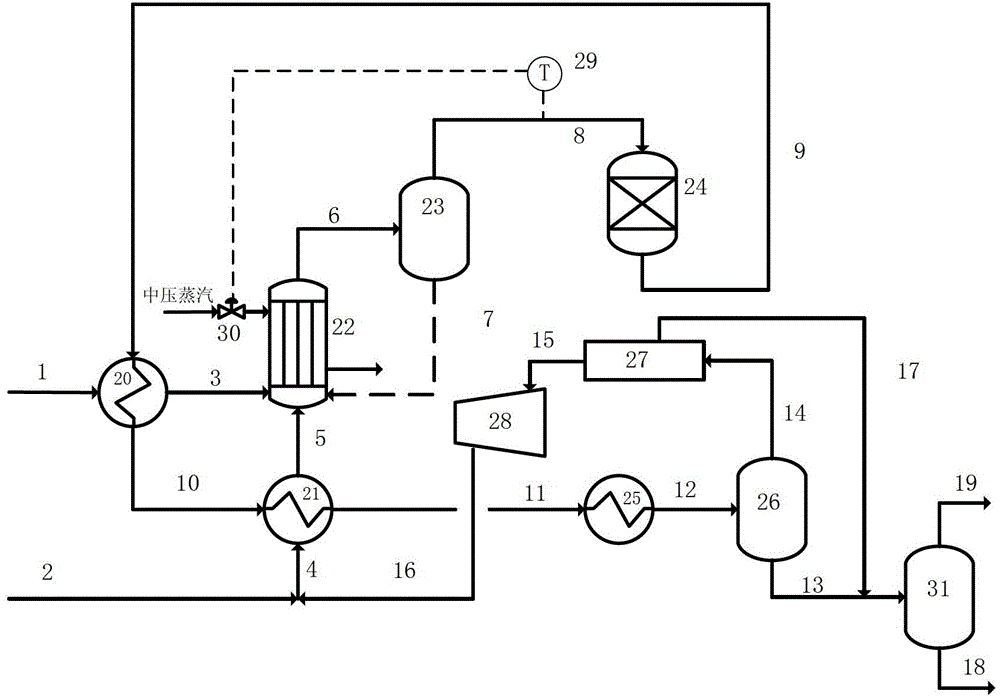

[0042] Combine below figure 1 Specific embodiments will be described. 3.5 L of hydrogenation Cu-based catalysts are loaded in the middle of the hydrogenation reactor 24, ceramic rings with the same particle size as the catalyst are installed at both ends of the reactor, and ethyl acetate is used as a raw material, and the reaction pressure of the hydrogenation reaction is 2.5 MPa (Table pressure).

[0043] Acetate 1 is pumped into the acetate preheater 20 by a high-pressure liquid feed pump, wherein the feed rate of acetate 1 is 2.65kg / h, and the high temperature product gas 9 from hydrogenation reactor 24 is in the acetate preheater Heat exchange preheating occurs in 20, and is heated to 240° C. in the acetate preheater 20 to obtain preheated acetate 3, which enters the bottom of the vaporizer 22 after preheating. During the reaction, the mixed hydrogen gas 4 obtained by mixing the fresh hydrogen gas 2 and the circulating hydrogen gas 16 is fed into the hydrogen gas preheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com