Single wire wound off-road rainforest tire

A single wire, off-road technology, applied in tire parts, reinforcement layers of pneumatic tires, tire tread/tread pattern, etc., can solve the problem of low utilization rate of steel wire breaking force, low tire burst resistance, and material waste and other problems, to achieve the effect of improving the performance of water blasting, eliminating the blasting phenomenon and reducing the probability of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

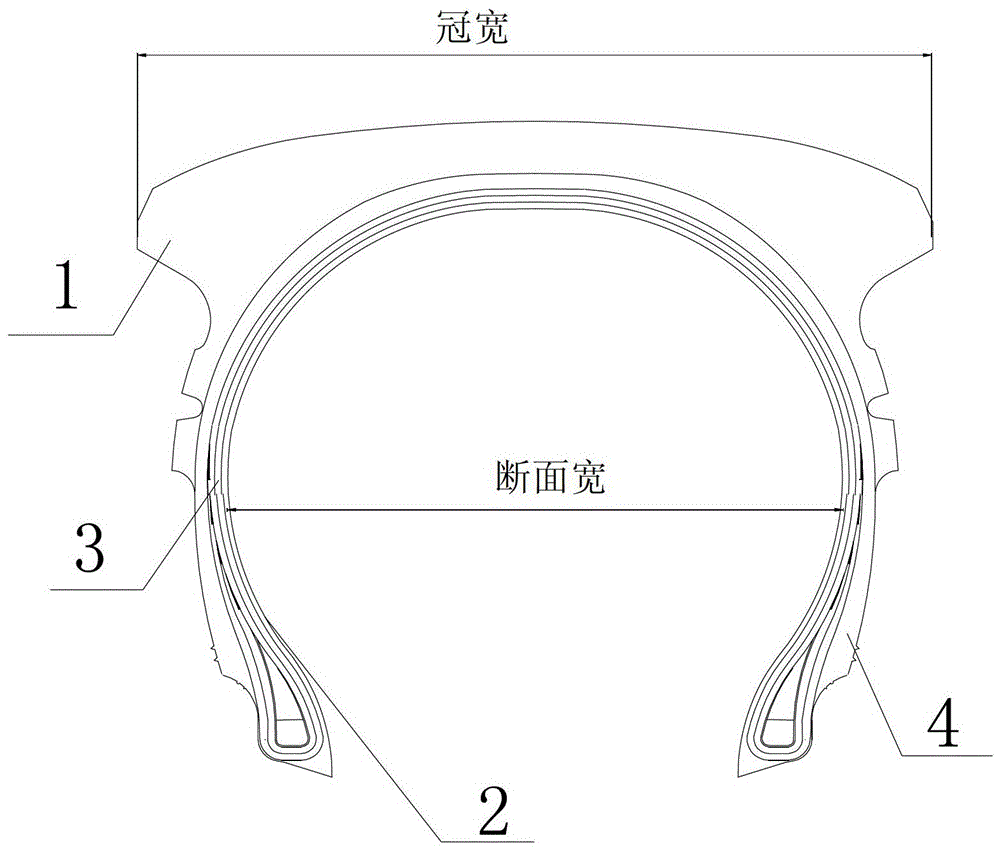

[0015] like figure 1 As shown, this embodiment includes a tread 1, an inner liner 2, a carcass layer 3 and a bead 4, the inner liner 2 is arched, the carcass layer 3 is wrapped outside the inner liner 2, and the bead 4 is a single steel wire Made by winding, the tread 1 is located on the top of the carcass layer 3; the carcass layer 3 is made of polyester cords, and the ratio of crown width to section width of the tire is 110-120%. The arch in this embodiment is composed of three arcs, and the radius ratio of the three arcs is 20:4:3.

[0016] The single steel wire winding technology greatly reduces the number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com