Automatic splitting robot system for livestock and poultry slaughtering

A robotic system, livestock and poultry technology, applied in control/adjustment systems, instruments, splitting tools, etc., can solve the problems of patent reports about automatic splitting robot systems for livestock and poultry slaughtering, non-compliance with food hygiene standards, meat damage and other problems. High labor intensity and other problems, to achieve the effect of avoiding thermal denaturation, low labor intensity, and preventing cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

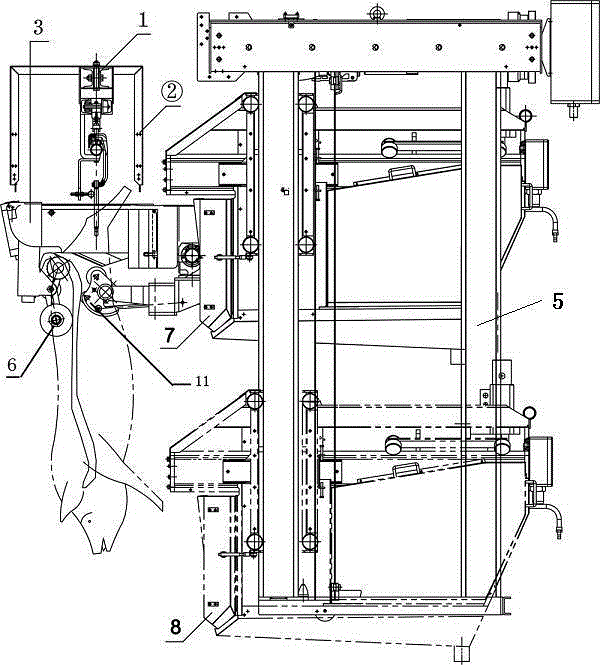

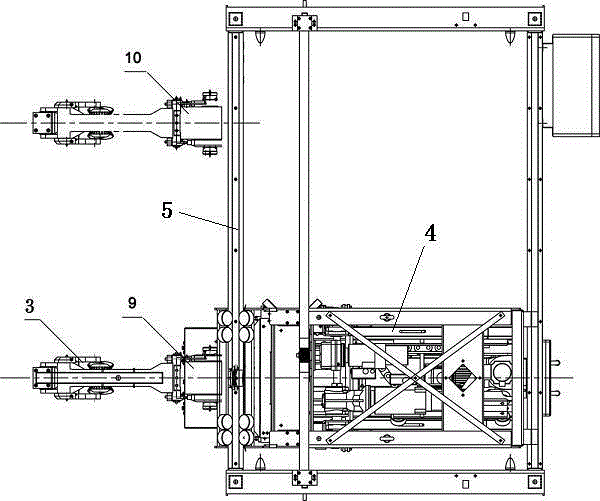

[0019] The structure of the present invention will be described in detail below in conjunction with the drawings:

[0020] Such as figure 1 , 2 As shown, the present invention includes a synchronous translation system 1 for hanging livestock and poultry. One side of the synchronous translation system 1 is provided with a double-knife alternating chopping system 3 that can move up and down. The operation route of the synchronous translation system 1 is one There is a real-time surveying and mapping automatic positioning system 2 on the side. The double-knife alternate chopping system 3 is equipped with an automatic washing device for washing its double blades. The double-blade alternate chopping system 3 is installed on the frame 5, and an automatic control system 4 for controlling the operation of the double-blade alternate chopping system 3 is also installed on the frame.

[0021] In the actual operation of the pig slaughter of the present invention, when the carcass on the carca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com