Method for improving quality and enhancing aroma of upper leaf of flue-cured tobacco

A technology for flue-cured tobacco and foliar fertilizer, which is applied in the fields of botanical equipment and methods, preparation of organic fertilizers, treatment of biological organic parts, etc., can solve the problems of insufficient oil content of tobacco leaves, low proportion of orange tobacco leaves, high energy and irritation, etc. Achieve improved use value and usability, enhanced aroma and texture, reduced energy and irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

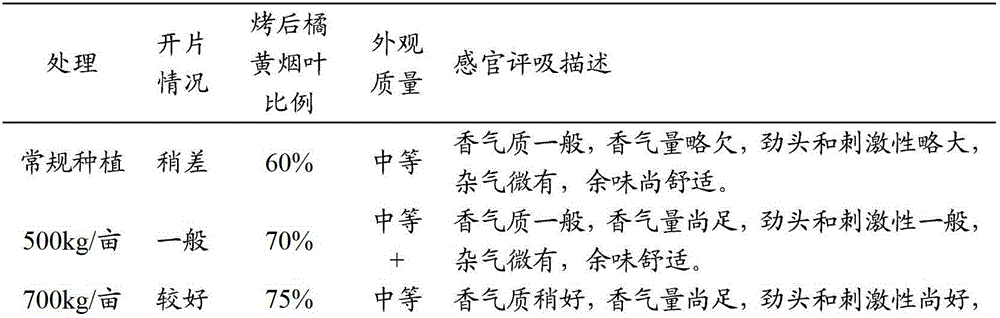

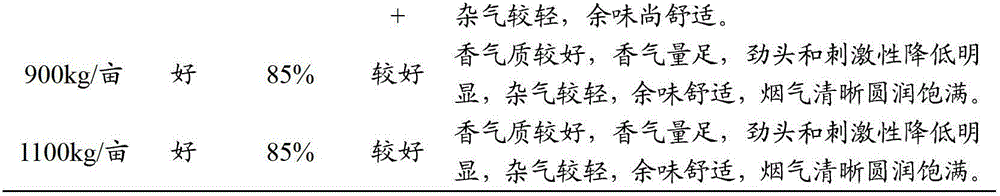

Embodiment 1

[0026] Embodiment 1: every mu increases the farmyard manure 800kg that decomposes, and wherein cake fertilizer 25kg, after middle part leaf gathers and finishes, every mu is sprayed by borax 20g, zinc sulfate 25g, manganese sulfate 30g, sodium molybdate 8g, copper sulfate 3g, Spray 15kg of jasmonic acid 0.2mg and other preparations on the leaves, and the harvest time is delayed by 5 days compared to normal, and the leaf color is close to 10% yellow.

Embodiment 2

[0027] Embodiment 2: every acre increases the farmyard manure 900kg that decomposes, and wherein cake fertilizer 25kg, after middle part leaf gathers and finishes, every acre is sprayed by borax 25g, zinc sulfate 30g, manganese sulfate 30g, sodium molybdate 6g, copper sulfate 2.5g , 0.2mg of jasmonic acid, etc., spraying 15kg of fertilizer on the leaves, the harvest time was delayed by 7 days compared to normal, and the color of the leaves was close to 10% yellow.

Embodiment 3

[0028] Embodiment 3: every mu increases the farmyard manure 1000kg that decomposes, and wherein cake fertilizer 30kg, after middle part leaf gathers and finishes, every mu is sprayed by borax 30g, zinc sulfate 25g, manganese sulfate 30g, sodium molybdate 6g, copper sulfate 2g, Spray 15kg of jasmonic acid 0.3mg and other preparations on the leaves, and the harvest time is 9 days later than normal, and the leaf color is close to 10% yellow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com