System for measuring booster noise

A supercharger and noise technology, which is applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as the inability to measure and analyze supercharger noise, achieve a wide range of changes, reduce noise, and measure accurately Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

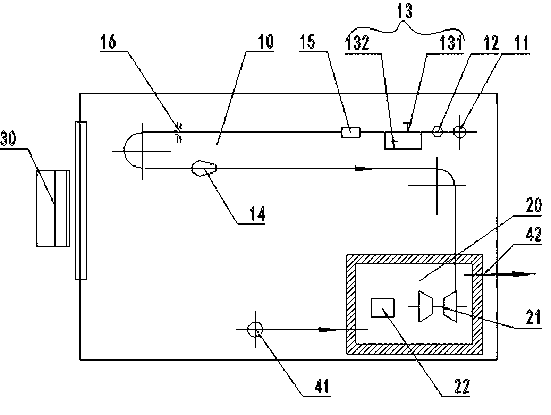

[0021] see figure 1 , a preferred embodiment of the present invention provides a system for measuring supercharger noise, comprising a turbine intake simulation device 10, a semi-anechoic chamber 20, which communicates with the gas outlet of the turbine intake simulation device 10 and is placed in a semi-anechoic chamber. The supercharger 21 in the chamber 20, the spectrum generator 22 built in the semi-anechoic chamber 20, the control device 30 for controlling the turbine air intake simulation device 10, and the intake parameters and semi-anechoic air intake parameters of the turbine air intake simulation device 10 are displayed. A display device for sound decibels in the sound chamber 20 (not shown in the drawings). The supercharger noise measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com