Performance detection testing system of mine air returning heat exchanger and using method thereof

A mine return air and test system technology, applied in the direction of instruments, measuring devices, etc., can solve the problems that have not been seen and cannot meet the heat load demand of users, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

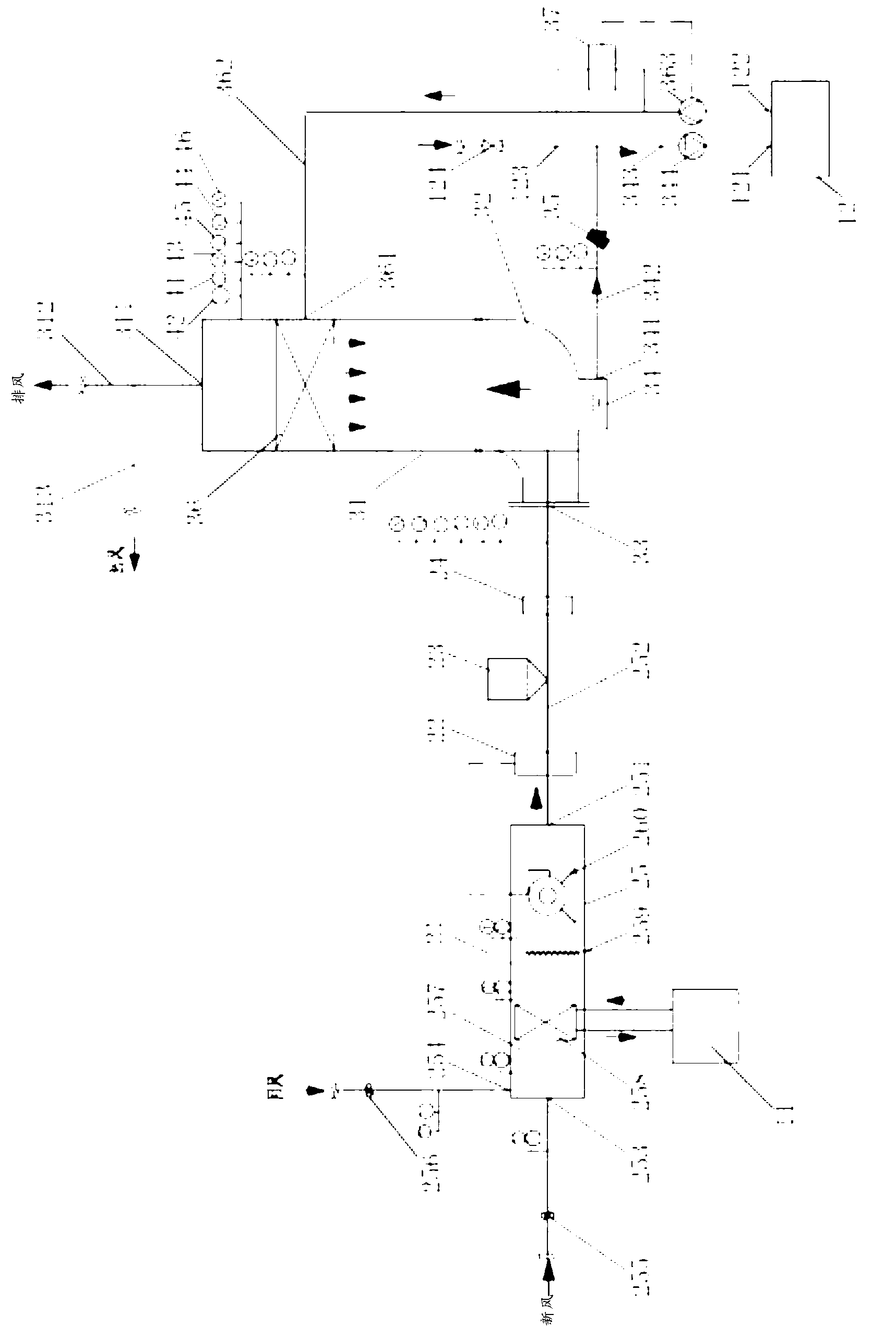

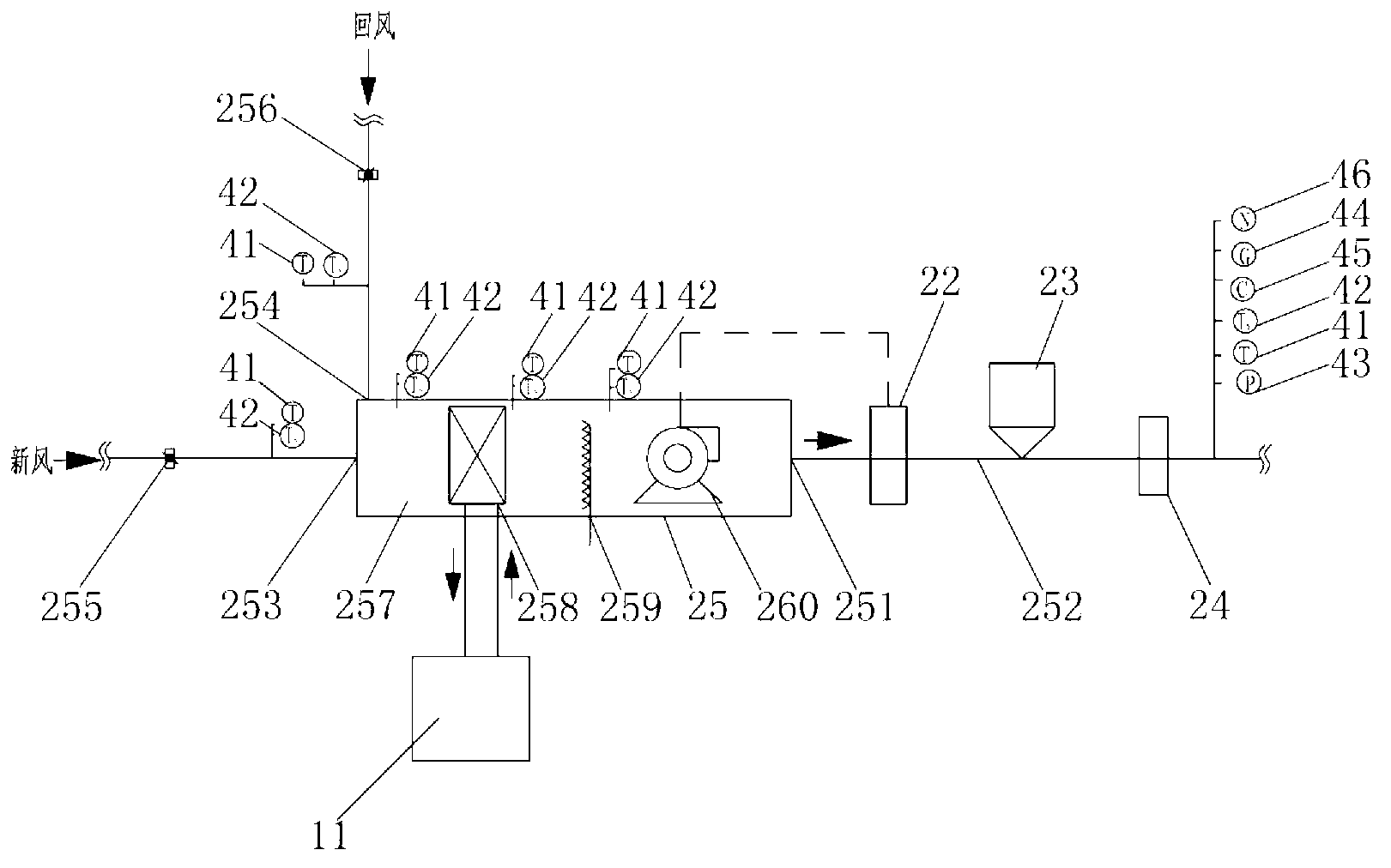

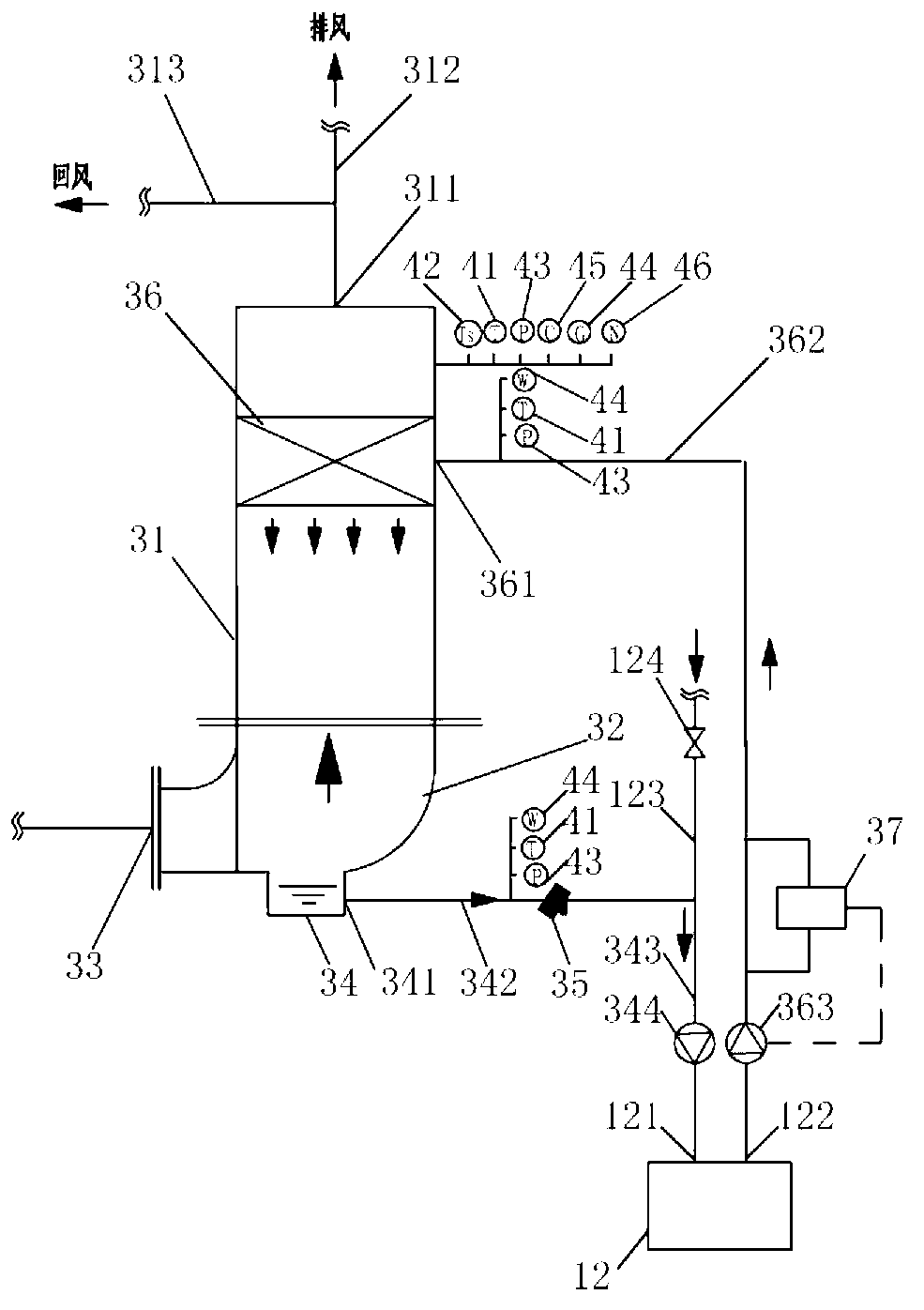

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] The invention includes a cold and heat source device, an air pretreatment device, a return air heat exchanger test device and a measurement control device.

[0026] Such as figure 1 As shown, the cold and heat source device of the present invention includes two heat pump unit units 11, 12, the heat pump unit unit 11 provides the required cooling capacity or heat for the air pretreatment device, and the heat pump unit unit 12 provides all the heat for the return air heat exchanger test device. Cooling or heating required. The heat pump unit units 11 and 12 are formed by connecting more than one heat pump unit in parallel.

[0027] The air pretreatment device of the present invention is used for simulating the underground return air parameters under the working conditions of winter, summer and transitional seasons in practical applications, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com