Method for installing steel cofferdam by the aid of pier supporting frame

A steel cofferdam and support frame technology, applied in the direction of construction and infrastructure engineering, can solve the problems that soil cofferdams and soil bag cofferdams cannot meet the requirements of construction, and can not meet the requirements, so as to facilitate quality and safety control, Simplified construction difficulty and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

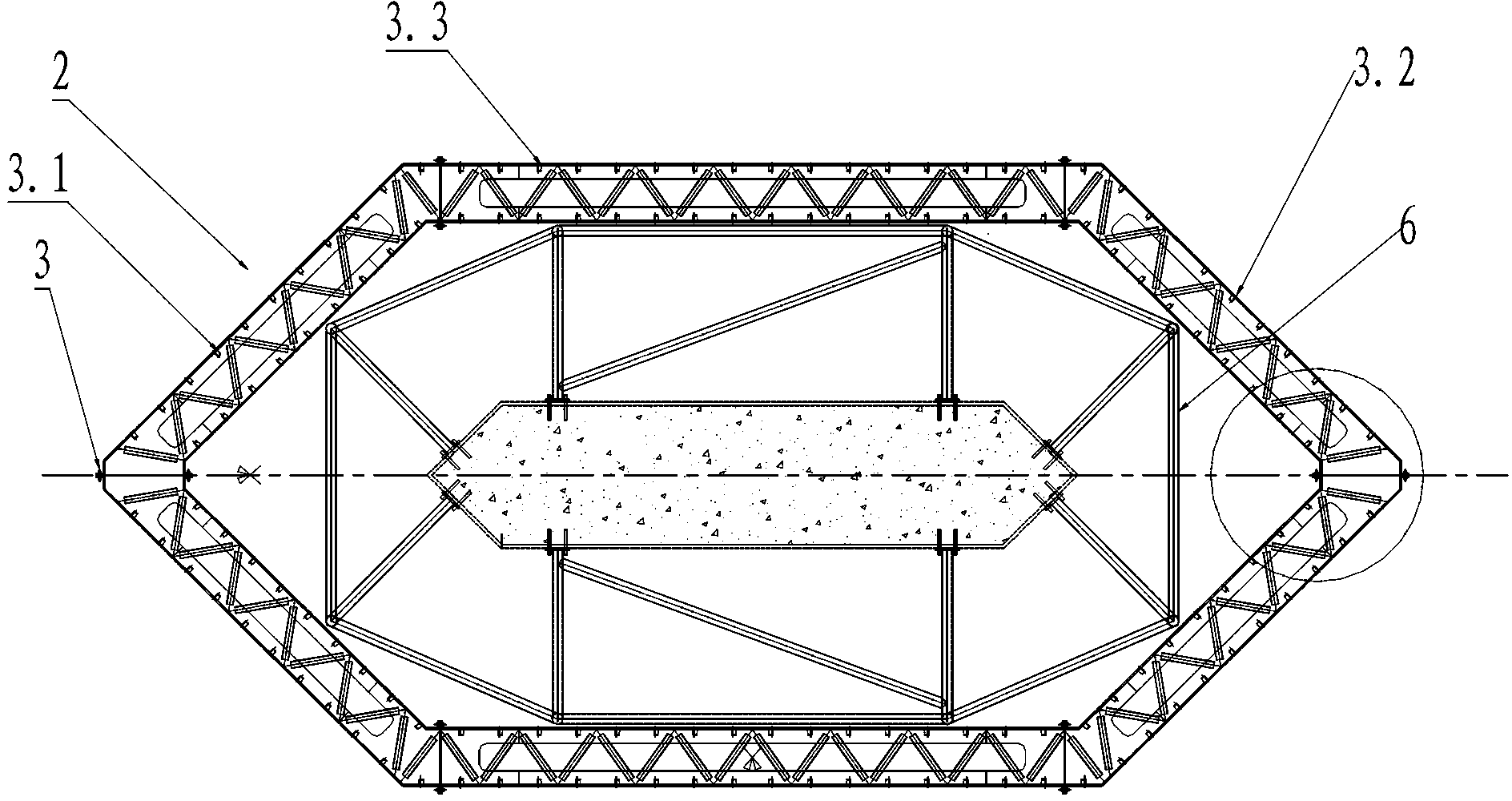

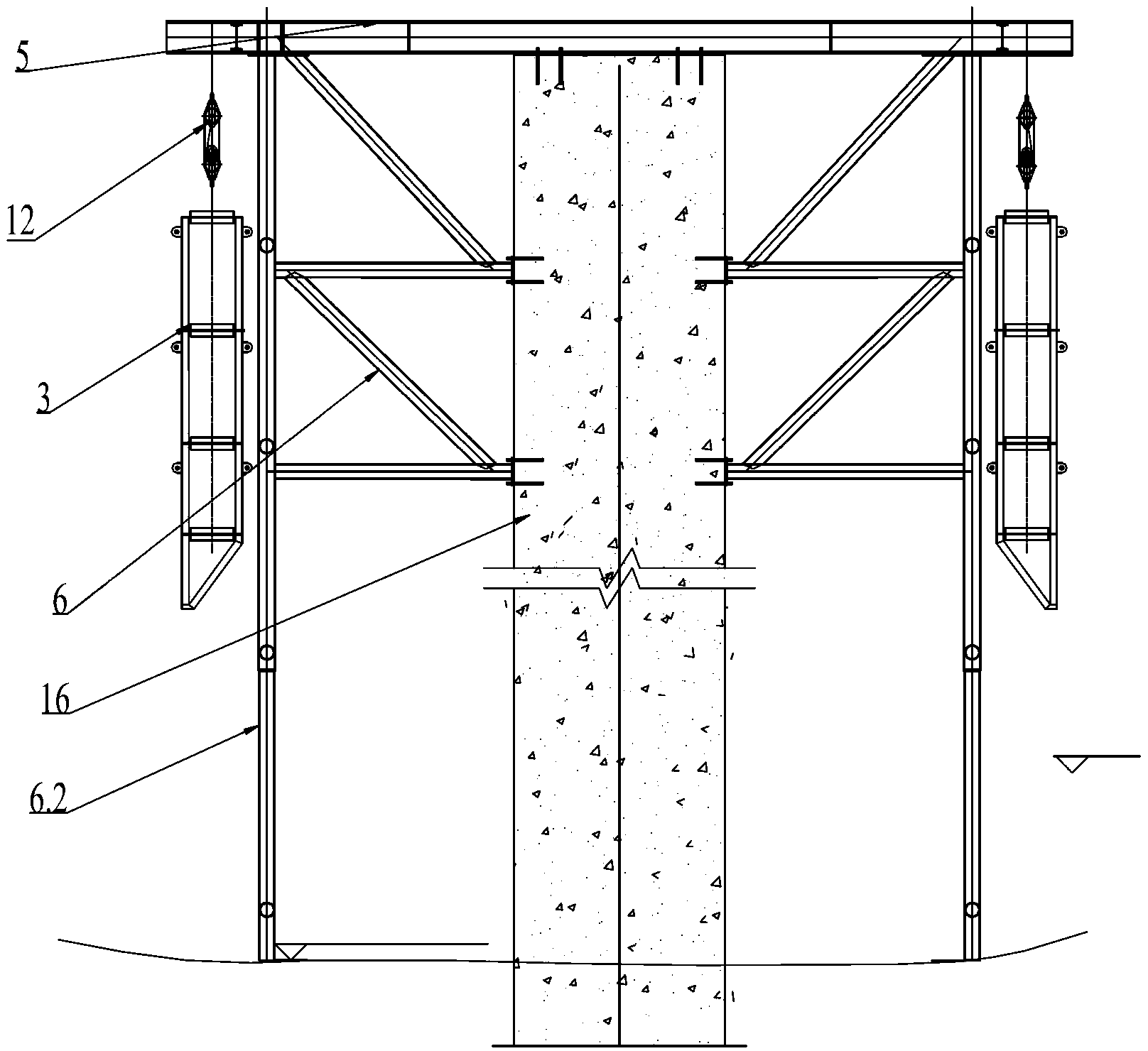

[0055] A method for installing a steel cofferdam by means of a pier support frame, comprising the steps of:

[0056] 1) Installation of hoisting frame:

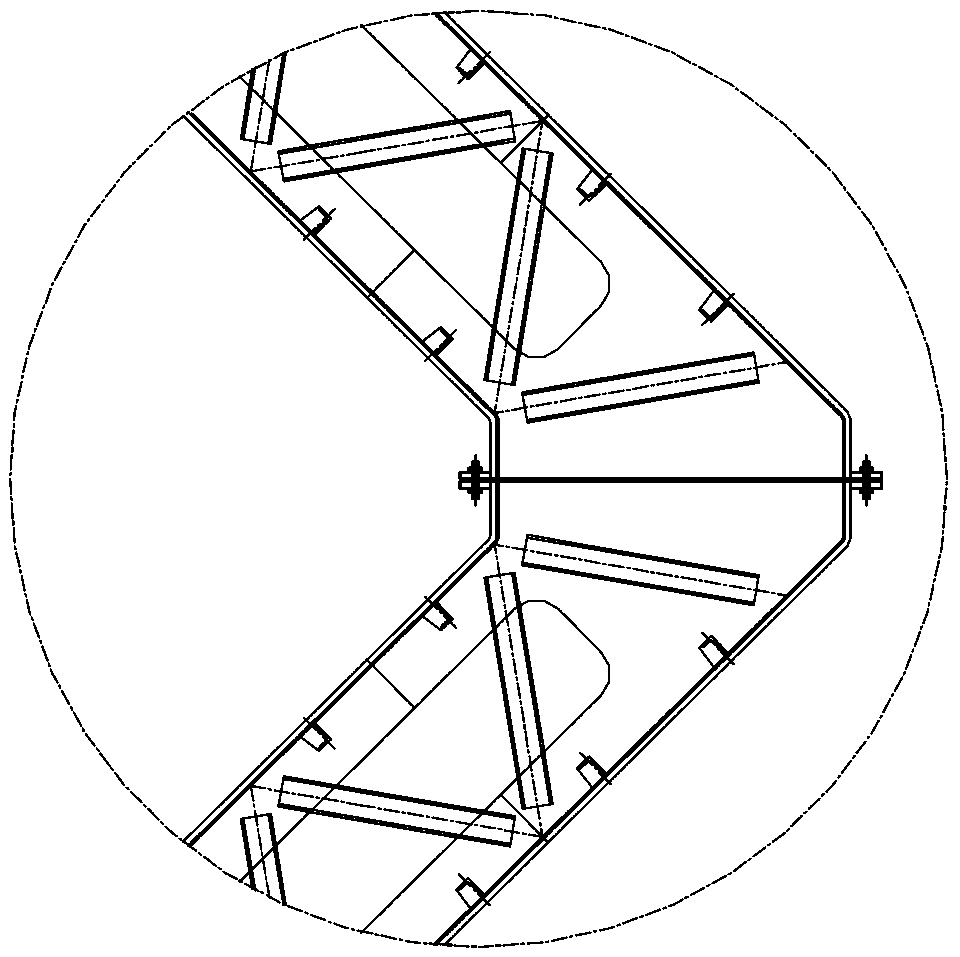

[0057] Such as Figure 6 The hoisting frame 5 shown includes a horizontal cantilever beam 5.1, a vertical cantilever beam 5.2 and a flat connecting rod 5.3. Due to insufficient bridge clearance, the hoisting frame is installed on the pier top of the bridge pier 16 in order to make reasonable use of the space. Specifically, the longitudinal cantilever beam 5.2 and the horizontal cantilever beam 5.1 are transported to the bridge pier by a transport ship, and then the longitudinal cantilever beam 5.2 is transported to the bridge pier. Hoisting is placed on the top of the pier, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com