Method for preparing doxofylline

A technology of doxofylline and theophylline, applied in the field of preparation of doxofylline, can solve problems such as product pollution, and achieve the effect of digesting organic solvent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

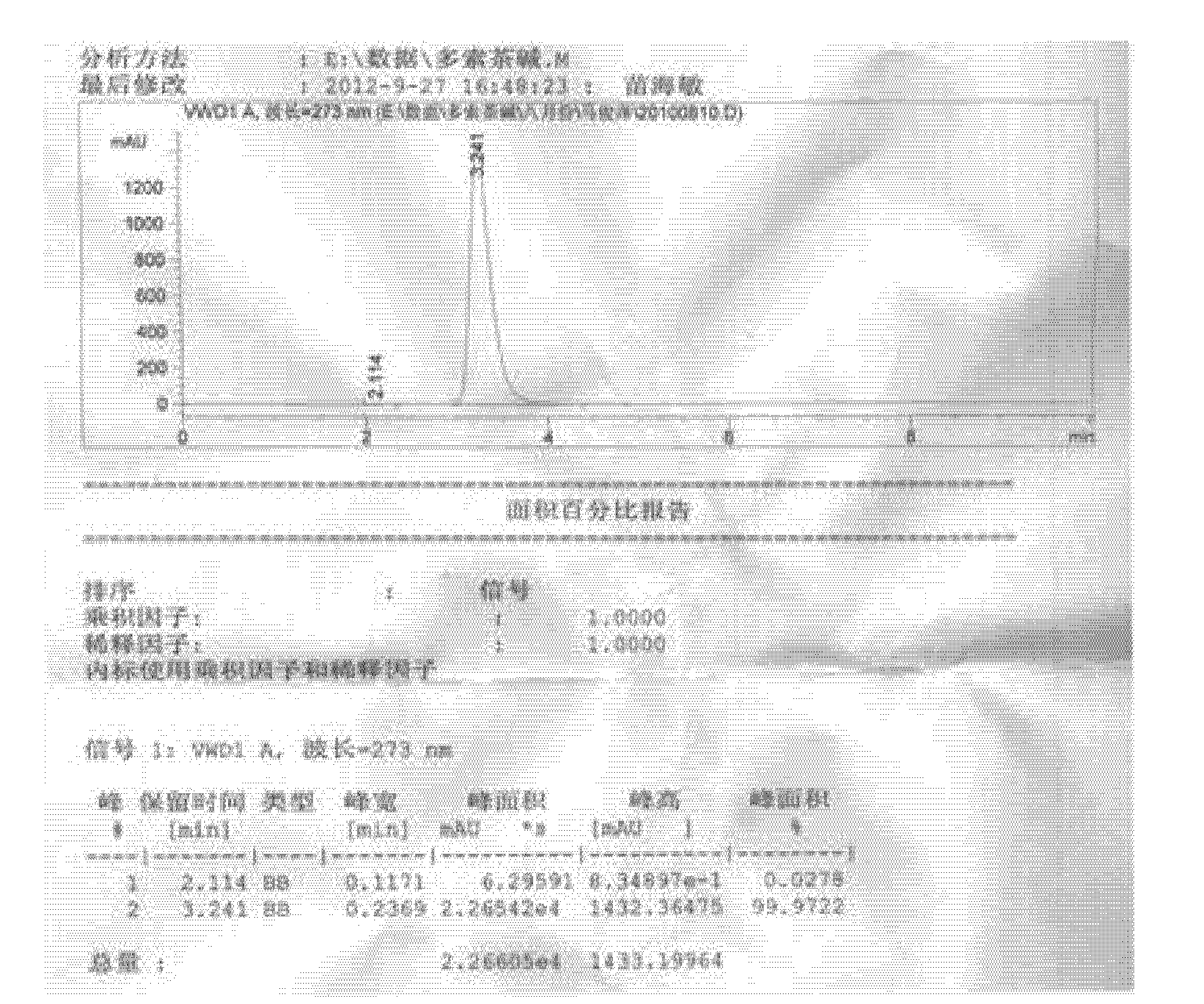

Image

Examples

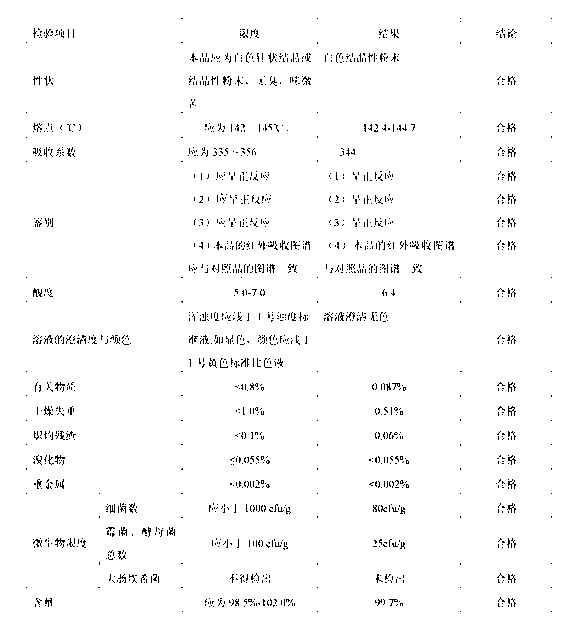

Embodiment 1

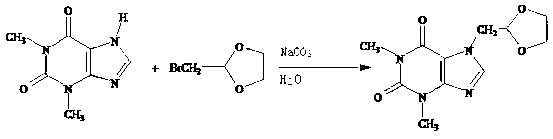

[0033] In the preparation method of doxofylline of the present invention, the detailed steps of the preparation method are as follows:

[0034] a. Take anhydrous theophylline and bromoacetaldehyde ethylene glycol as basic raw materials, use purified water as solvent, and anhydrous sodium carbonate as acid binding agent;

[0035] The mass ratio of the added amount between the anhydrous theophylline and bromoacetaldehyde ethylene glycol is 1:1.02, and the mass ratio of the added amount between the anhydrous theophylline and purified water is 1:10, The mass ratio between anhydrous theophylline and anhydrous sodium carbonate is 1:0.97;

[0036] b. Prepare various raw materials in the ratio between the raw materials described in step a. First, add 10.0 g of anhydrous theophylline, 9.7 g of anhydrous sodium carbonate and 100 ml of solvent purified water into the reaction vessel, and then heat to 100 ℃, keep stirring and refluxing during heating to completely dissolve the anhydrous theophy...

Embodiment 2

[0041] In the preparation method of doxofylline of the present invention, the detailed steps of the preparation method are as follows:

[0042] a. Take anhydrous theophylline and bromoacetaldehyde ethylene glycol as basic raw materials, use purified water as solvent, and anhydrous sodium carbonate as acid binding agent;

[0043] The mass ratio of the added amount between the anhydrous theophylline and bromoacetaldehyde glycol acetal is 1:1.2, and the mass ratio of the added amount between the anhydrous theophylline and purified water is 1:9, The mass ratio between the anhydrous theophylline and anhydrous sodium carbonate is 1:0.6;

[0044] b. Prepare various raw materials in the ratio between the raw materials described in step a. First, add 10.0 g of anhydrous theophylline, 6.0 g of anhydrous sodium carbonate and 90 ml of solvent purified water into the reaction vessel, and then heat to 110 ℃, keep stirring and refluxing during heating to completely dissolve the anhydrous theophyll...

Embodiment 3

[0049] In the preparation method of doxofylline of the present invention, the detailed steps of the preparation method are as follows:

[0050] a. Take anhydrous theophylline and bromoacetaldehyde ethylene glycol as basic raw materials, use purified water as solvent, and anhydrous sodium carbonate as acid binding agent;

[0051] The mass ratio of the added amount between the anhydrous theophylline and bromoacetaldehyde glycol acetal is 1:1.0, and the mass ratio of the added amount between the anhydrous theophylline and purified water is 1:11, The mass ratio between anhydrous theophylline and anhydrous sodium carbonate is 1:0.85;

[0052] b. Prepare various raw materials in the ratio between the raw materials described in step a. First, add 10.0 g of anhydrous theophylline, 8.5 g of anhydrous sodium carbonate and 110 ml of solvent purified water into the reaction vessel, and then heat to 105 ℃, keep stirring and refluxing during heating to completely dissolve the anhydrous theophylli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com