Large-pipe-diameter shell section pair group extension device

A technology of large pipe diameter and cylinder section is applied in the field of pipeline prefabrication processing equipment and large pipe diameter cylinder section group docking device, which can solve the problems of low production efficiency, complicated construction process and long production cycle, and achieves low cost and high installation cost. The effect of simple structure and less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

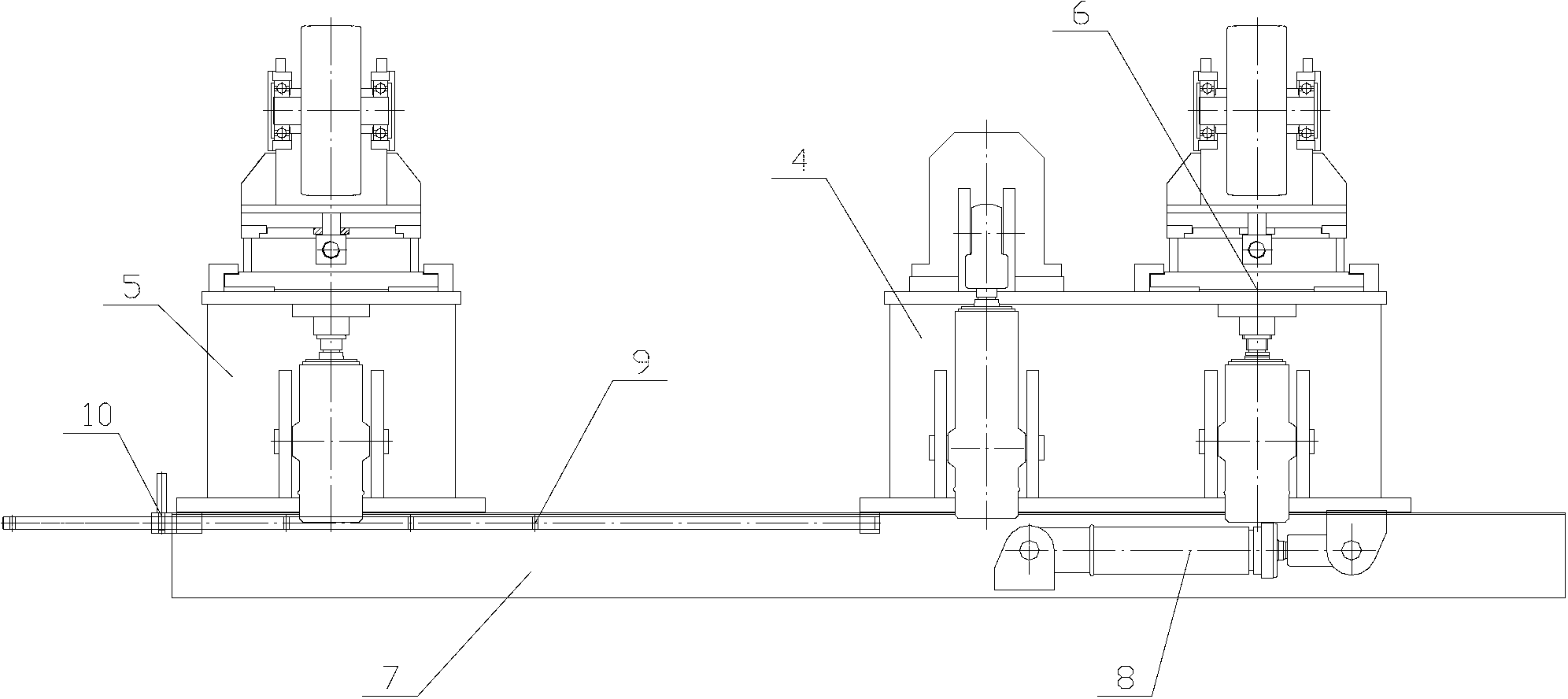

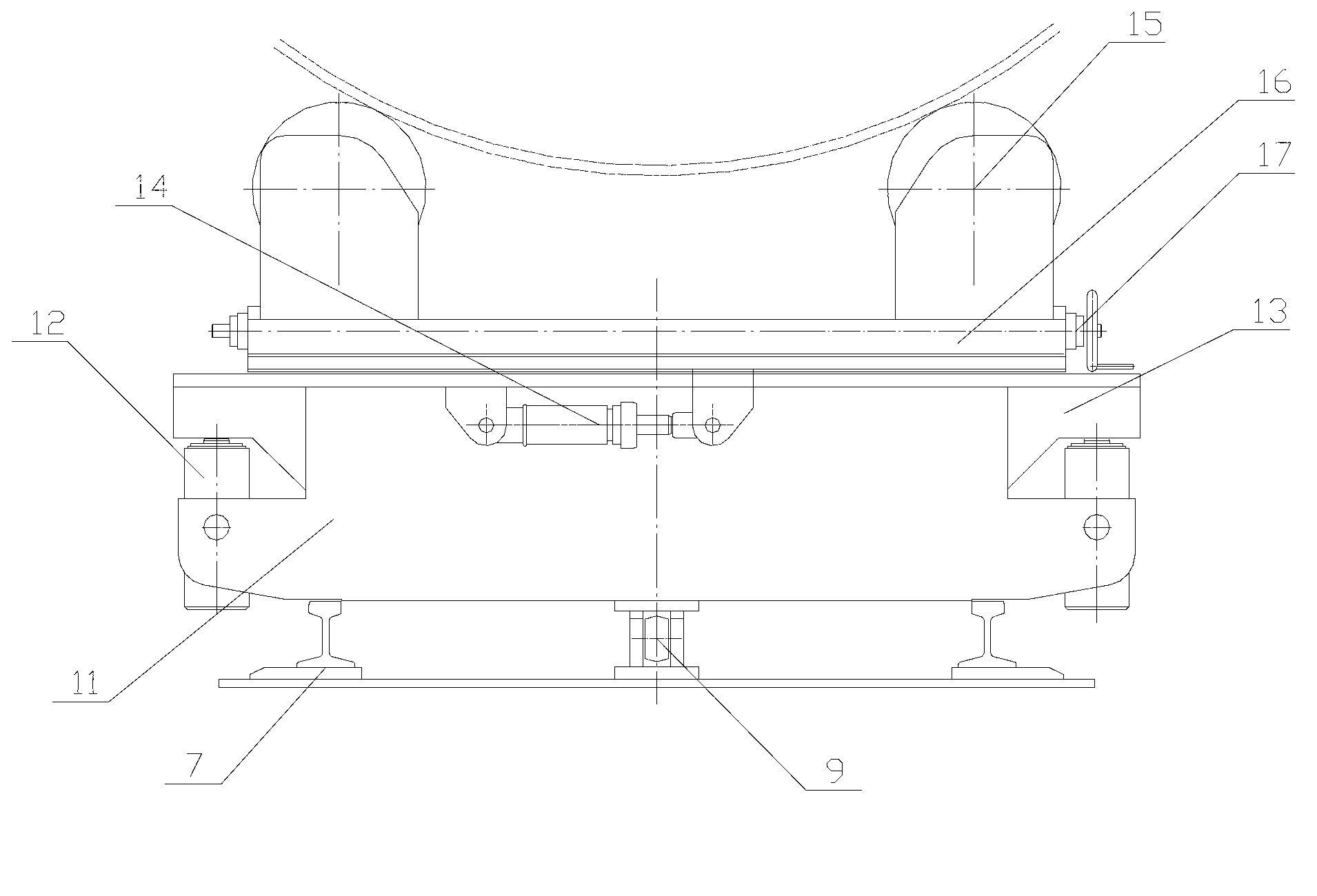

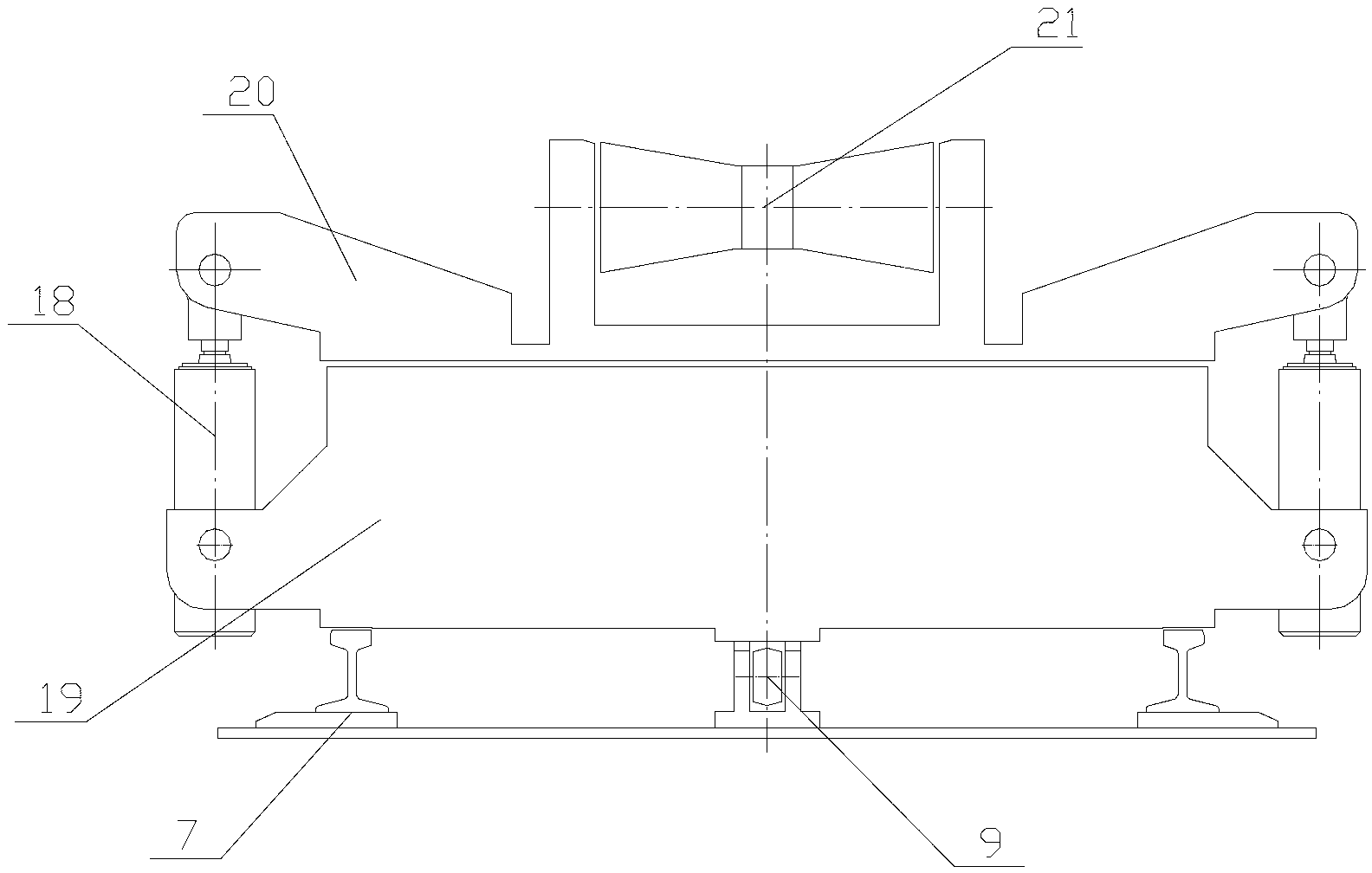

[0018] This embodiment provides a long pipe butt joint device with large pipe diameter, the structure is as follows: Figure 1 to Figure 3 As shown, it includes a sleeve joint three-dimensional adjustment device 1 and four conveying roller frames. Among the four conveying roller frames, two are active conveying roller frames 2, and two are conveying driven roller frames 3. The conveying roller frame 2 is located between the two driven conveying roller frames 3, and the electric motor of the active conveying roller frame provides the power to rotate the drum section during alignment, and the four conveyor roller frames and the three-dimensional adjustment device of the drum section 1 are installed side by side on a straight line; the cylinder joint three-dimensional adjustment device 1 includes a conveying roller frame 4 installed on the bottom guide rail 7, a first roller frame 5 and a second roller frame 6, and the conveying roller frame 4 is installed on the first roller Bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com